36 MS-SVN056C-EN

Outdoor Unit Installation

Procedure for pipe connection

1. Measure the required length of tube connection and proceed as follows. First

connect the indoor unit; then connect the outdoor unit.

– Fold the pipe appropriately. Do not twist the tube.

– Apply refrigerant oil on the surface of the flared pipe and on the union nuts; using hands, apply

tightening torque for 3 to 4 turns, before using the wrench.

– Employ two open-end wrenches simultaneously to connect or disconnect piping

• Outdoor unit service valves must be totally closed (original state). In order to connect them, loosen the

nuts and connect flared tubes in a timing not to exceed 5 minutes. If nuts remain loose during extended

time, it could lead to dust and other debris entering the system and consequently causing a system

malfunction. Therefore, before the final connection, purge air from the refrigerant line.

• Purge air after connecting the refrigerant line to both indoor unit and outdoor unit. Tighten nuts on the

service valves.

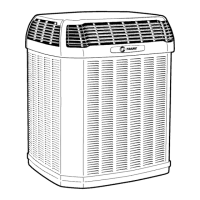

• Fold the thin-walled connecting tube.

– Cut the insulation material insulating material all over the pipe on the section to be folded.

– Expose the pipe. Proceed to fold it. Once folded, cover it completely with insulating material

– In order to prevent pipe from deforming or twisting, fold it at a suitable radius.

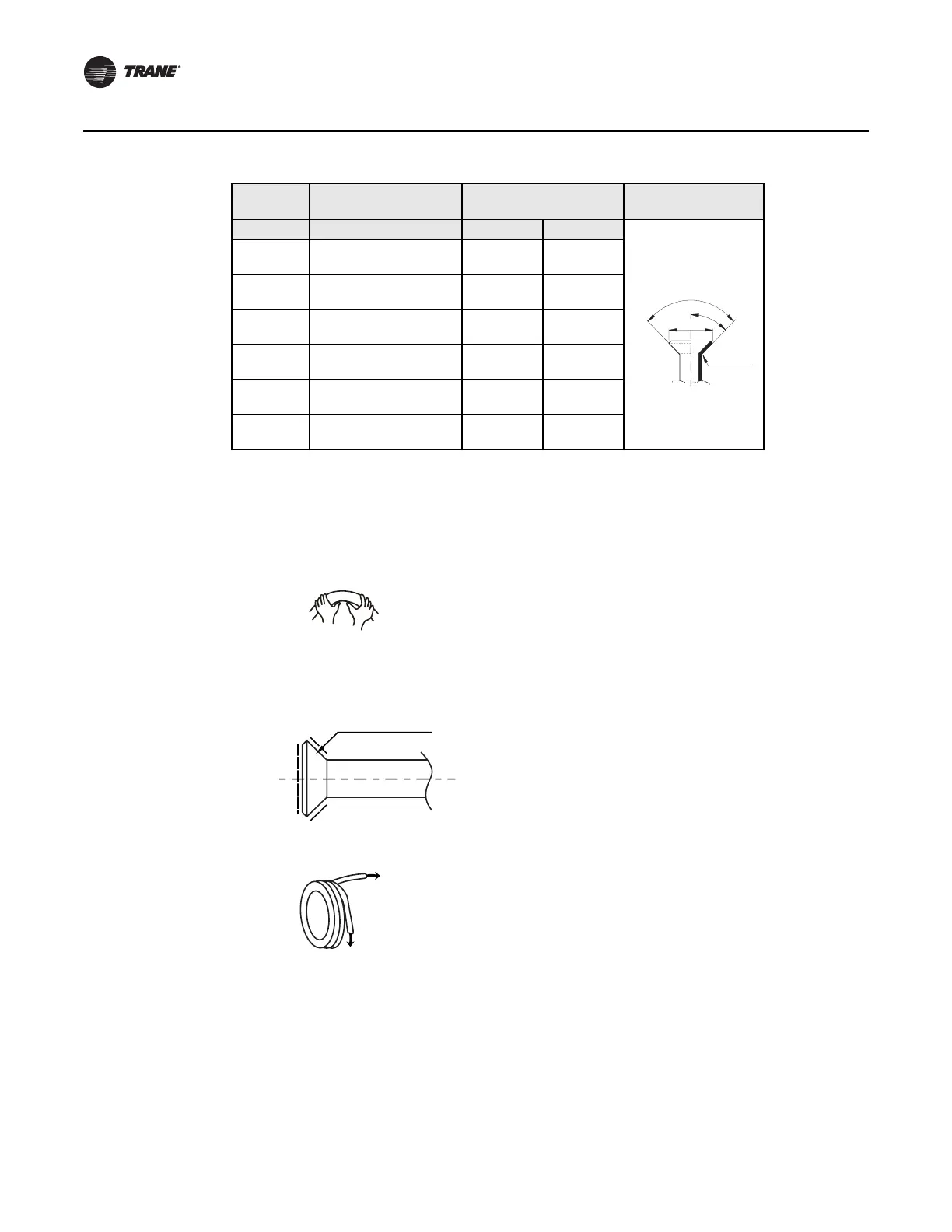

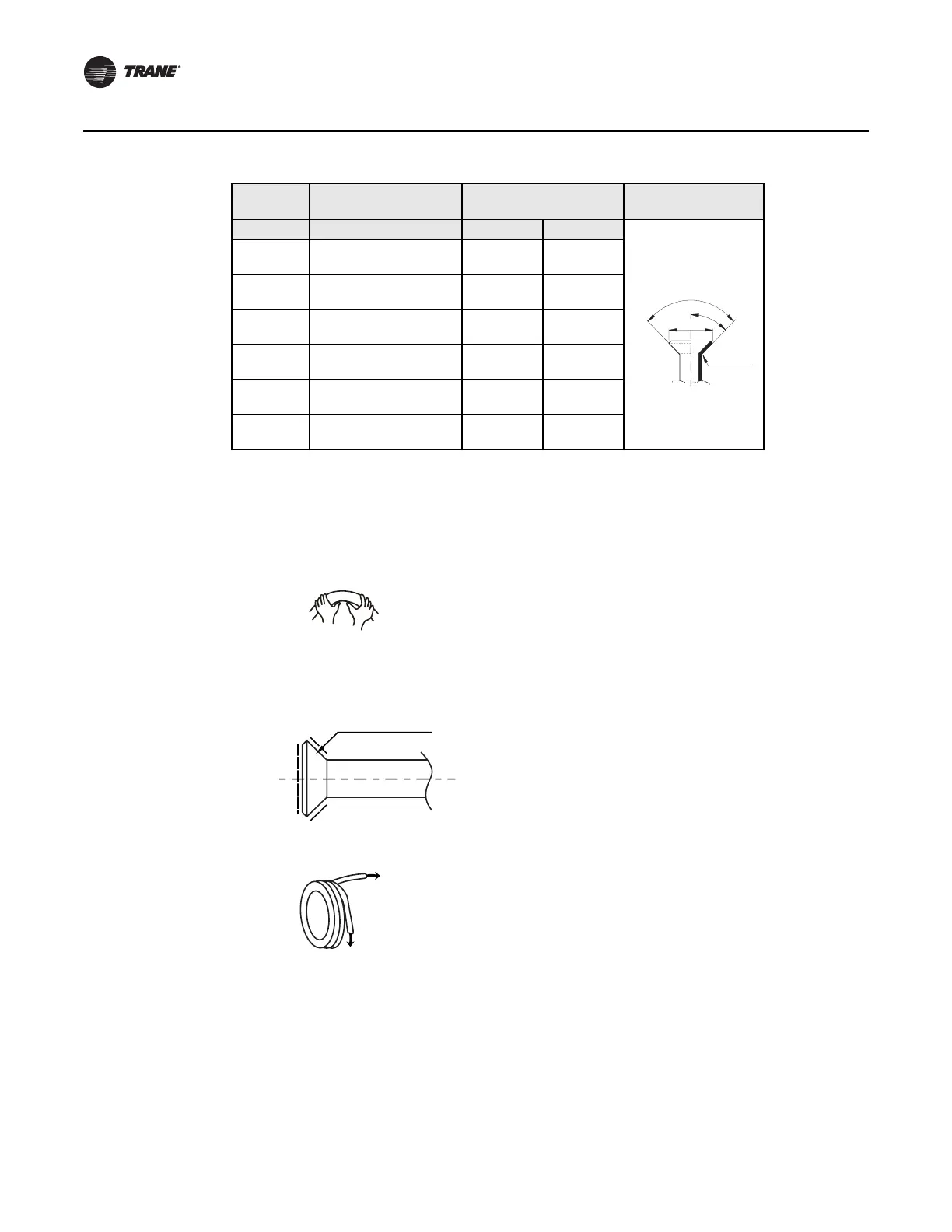

Tube

Diameter

Tightening Torque

Flare dimension (A)

(mm/inch) Flaring

Min. Max.

φ 6.4

14.2 + 17.2 N.m.

(144-176 kgf.cm)

8.3/0.3 8.3/0.3

φ 9.5

32.7 + 39.9 N.M

(333-407 kgf.cm)

12.4/0.48 12.4/0.48

φ 12.7

49.5 + 60.3 N.M

(504-616 kgf.cm)

15.4/0.6 15.8/0.6

φ 15.9

61.8 + 75.4 N.M

(630-770 kgf.cm)

18.6/0.7 19/0.74

φ 19.1

97.2 + 118.6 N.M

(990-1210 kgf.cm)

22.09/0.9 23.3/0.91

φ 22

109.5 + 133.7 N.M

(1117-1364 kgf.cm)

27/1.06 27.3/1.07

Fold pipe using thumbs at a

minimum radius of 100mm/3.94in

Loading...

Loading...