12 18-AC104D1-1G-EN

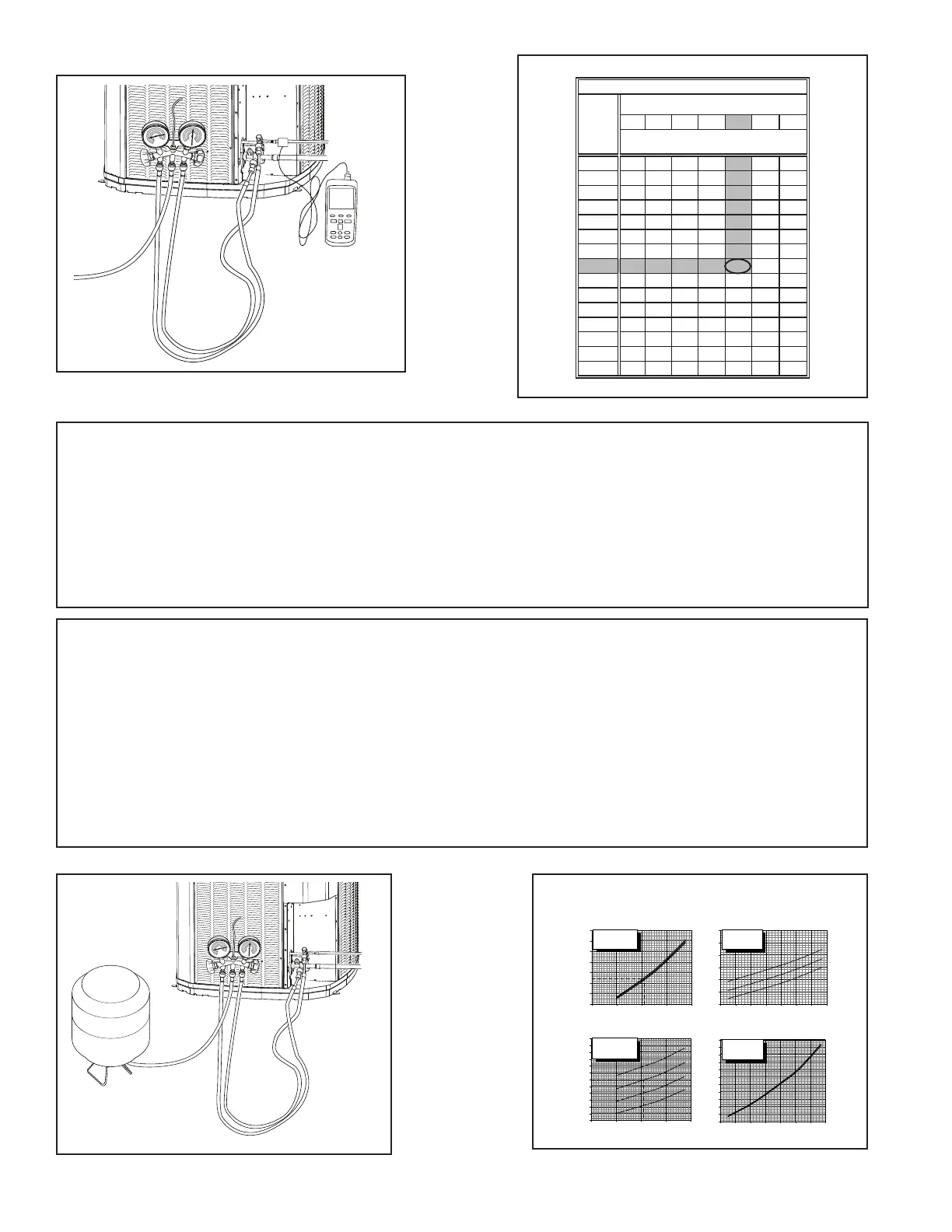

Table 14.2

8910 11 12 13 14

179 182 185 188 191 195 198

195 198 201 204 208 211 215

211 215 218 222 225 229 232

229 232 236 240 243 247 251

247 251 255 259 263 267 271

267 271 275 279 283 287 291

287 291 296 300 304 309 313

309 313 318 322 327 331 336

331 336 341 346 351 355 360

355 360 365 370 376 381 386

381 386 391 396 402 407 413

407 413 418 424 429 435 441

435 441 446 452 458 464 470

464 470 476 482 488 495 501

495 501 507 514 520 527 533

R-410A REFRIGERANT CHARGING CHART

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

LIQUID

TEMP

(

°

F)

FINAL SUBCOOLING (

°

F)

LIQUID GAGE PRESSURE (PSI)

From Dwg. D154557P01 Rev. 3

107 °F

STEP 6 - Adjust refrigerant level to attain proper gage pressure.

Add refrigerant if the Liquid Gage Pressure is lower than the chart value.

1. Connect gages to refrigerant bottle and unit as illustrated.

2. Purge all hoses.

3. Open bottle.

4. Stop adding refrigerant when liquid line temperature and Liquid Gage Pressure matches the charging char t

Final Subcooling value.

Recover refrigerant if the Liquid Gage Pressure is higher than the chart value.

STEP 7 - Stabilize the system.

1. Wait 20 minutes for the system condition to stabilize between adjustments.

Note: When the Liquid Line Temperature and Gage Pressure approximately match the chart, the system

is properly charged.

2. Remove gages.

3. Replace service port caps to prevent leaks. Tighten finger tight plus an additional 1/6 turn.

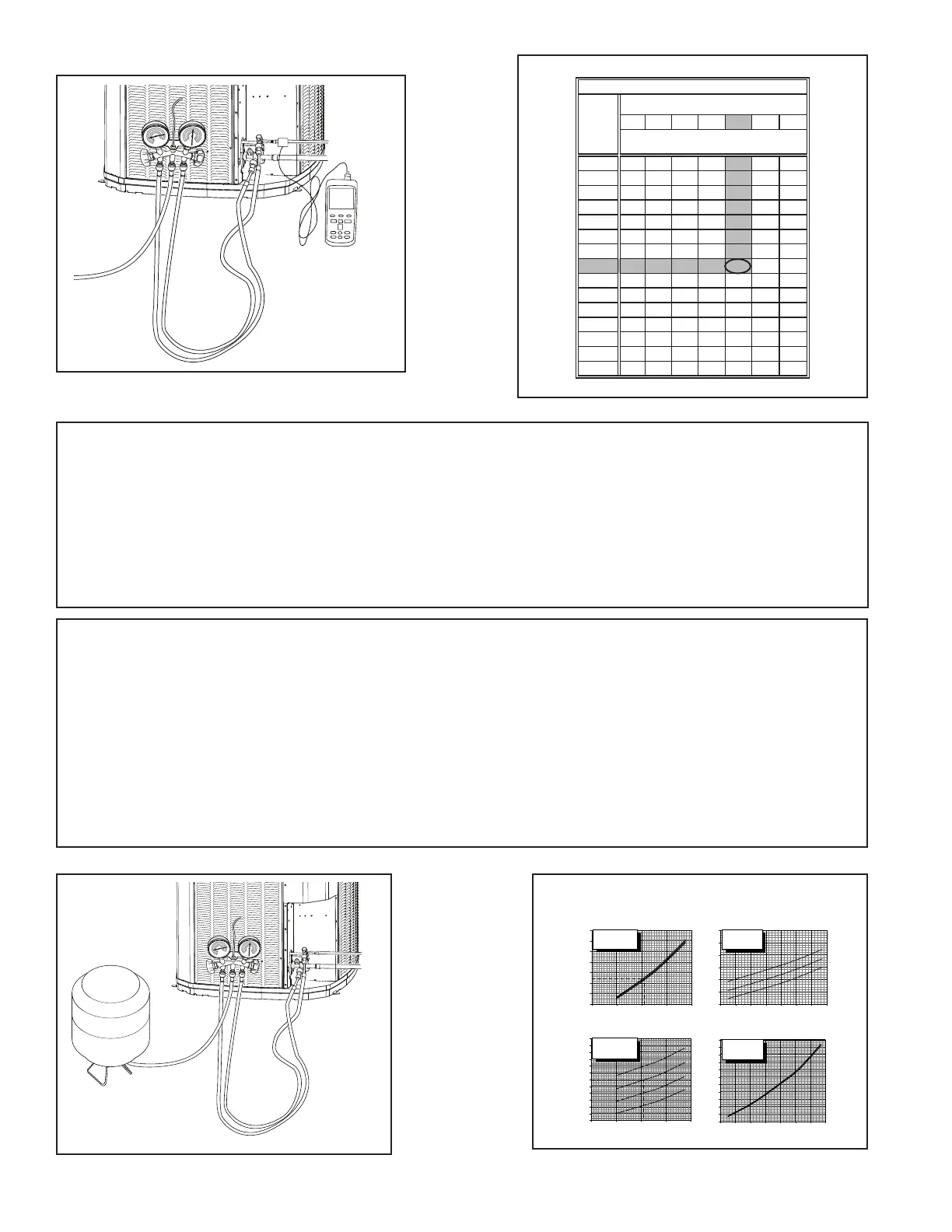

STEP 8 - Verify typical performance.

Refer to System Pressure Curves at the end of this document to verify typical performance.

(Example only)

PRESSURE CURVES FOR 4TWX5049E1

4TEE3F49C1 4TEE3F49C1

Cooling @ 1450 SCFM Heating @ 1350 SCFM

DISCHARGE PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

SUCTION PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

COOLING PERFORMANCE CAN BE CHECKED WHEN THE OUTDOOR TEMP IS ABOVE 65 DEG F.

TO CHECK COOLING PERFORMANCE, SELECT THE PROPER INDOOR CFM, ALLOW PRESSURES TO STABILIZE. MEASURE INDOOR WET BULB

TEMPERATURE, OUTDOOR TEMPERATURE, DISCHARGE AND SUCTION PRESSURES. ON THE PLOTS LOCATE OUTDOOR TEMPERATURE (1);

LOCATE INDOOR WET BULB (2); FIND INTERSECTION OF OD TEMP. & ID W.B. (3); READ DISCHARGE OR SUCTION PRESSURE IN LEFT

COLUMN (4).

EXAMPLE: (1) OUTDOOR TEMP. 82 F.

(2) INDOOR WET BULB 67 F.

(3) AT INTERSECTION ACTUAL:

(4) DISCHARGE PRESSURE @ 1450 CFM IS 323 PSIG DISCHARGE PRESSURE SHOULD BE +/- 10 PSI OF CHART

(5) SUCTION PRESSURE @ 1450 CFM IS 140 PSIG SUCTION PRESSURE SHOULD BE +/- 3 PSIG OF CHAR

INTERCONNECTING LINES

GAS - 7/8" O.D.

LIQUID - 3/8" O.D.

DWG.NO. 4TWX5049E1

110

115

120

125

130

135

140

145

150

155

160

165

170

40 60 80 100 120

200

250

300

350

400

450

500

550

40 60 80 100 120

(1)

(1)

(3)

(3)

(5)

(4)

(2)

(2)

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM

71, 67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM

71, 67, 63 AND 59 DEG F.

30

40

50

60

70

80

90

100

110

120

130

140

-5 5 15 25 35 45 55 65

200

250

300

350

400

450

500

-5 5 15 25 35 45 55 65

INDOOR ENTERING

DRY BULB CURVES

TOP TO BOTTOM

80, 70, AND 60 DEG F.

INDOOR ENTERING

DRY BULB CURVES

TOP TO BOTTOM

80, 70, AND 60 DEG F.

Loading...

Loading...