CAUJ-SVX01E-EN

35

• Maximum allowable pressure drop: 7 psig (1°F)

As the pressure drop in the liquid line increases, the

potential for liquid flashing, due to reduced refrigerant

pressure corresponding to a reduced liquid

temperature (subcooling), increases. Under these

conditions, liquid lines exposed to high surrounding

ambient temperatures must be insulated.

NNoottee:: Adding refrigerant to a system with improperly

sized refrigerant lines will only decrease system

performance and reliability and accentuate poor

operating condition.

Isolate all refrigerant lines from the building. This

prevents transferring line vibration to the structure. Do

not secure the lines rigidly to the building at any point

since this will defeat the isolation system of the unit.

See connection drawings in Dimension and Weights

chapter for refrigerant line size connections and

locations. Connect the liquid line piping to the stubs

provided at the liquid line shutoff valves.

NNoottee:: The installer must cut an appropriately-sized

opening in the unit sheet metal for the

refrigerant piping entrance into the unit.

Discharge (Hot Gas) Lines

Discharge lines should be pitched downward 1/2 inch

for each 10 feet of horizontal run in the direction of hot

gas flow and away from the compressor. Insulate any

portion of the discharge piping that is exposed to

outdoor ambient temperature.

Discharge line sizing is based on minimum velocity

required for good oil movement in system.

Basic discharge line parameters are:

• Maximum allowable pressure drop: 6 psig

• Maximum velocity: 3500 fpm

Minimum velocities at Minimum Load:

• Horizontal Lines: 500 fpm

• Vertical Lines: See table below.

A double riser system may be necessary to meet the

discharge line velocity requirements.

When either a single or double discharge riser is used,

the line should drop well below the discharge outlet of

the compressor before starting the vertical rise to

prevent the possibility of refrigerant draining back to

the compressor during the “Off” cycle.

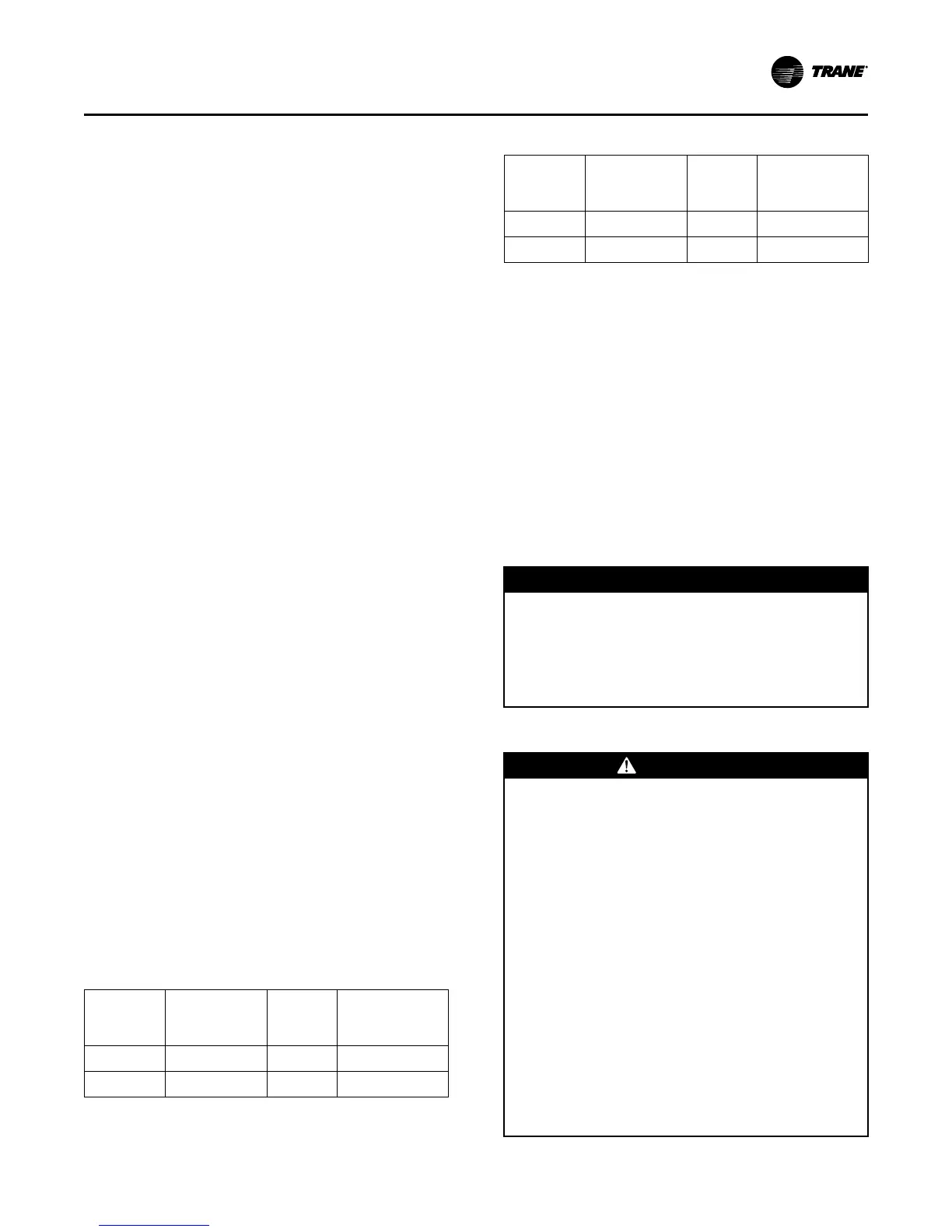

Table 12. Minimum vertical line velocities

Line Dia.

Minimum

Velocity

(fpm)

Line

Dia.

Minimum

Velocity (fpm)

7/8"

470

2-1/8"

750

1-1/8"

540

2-5/8"

825

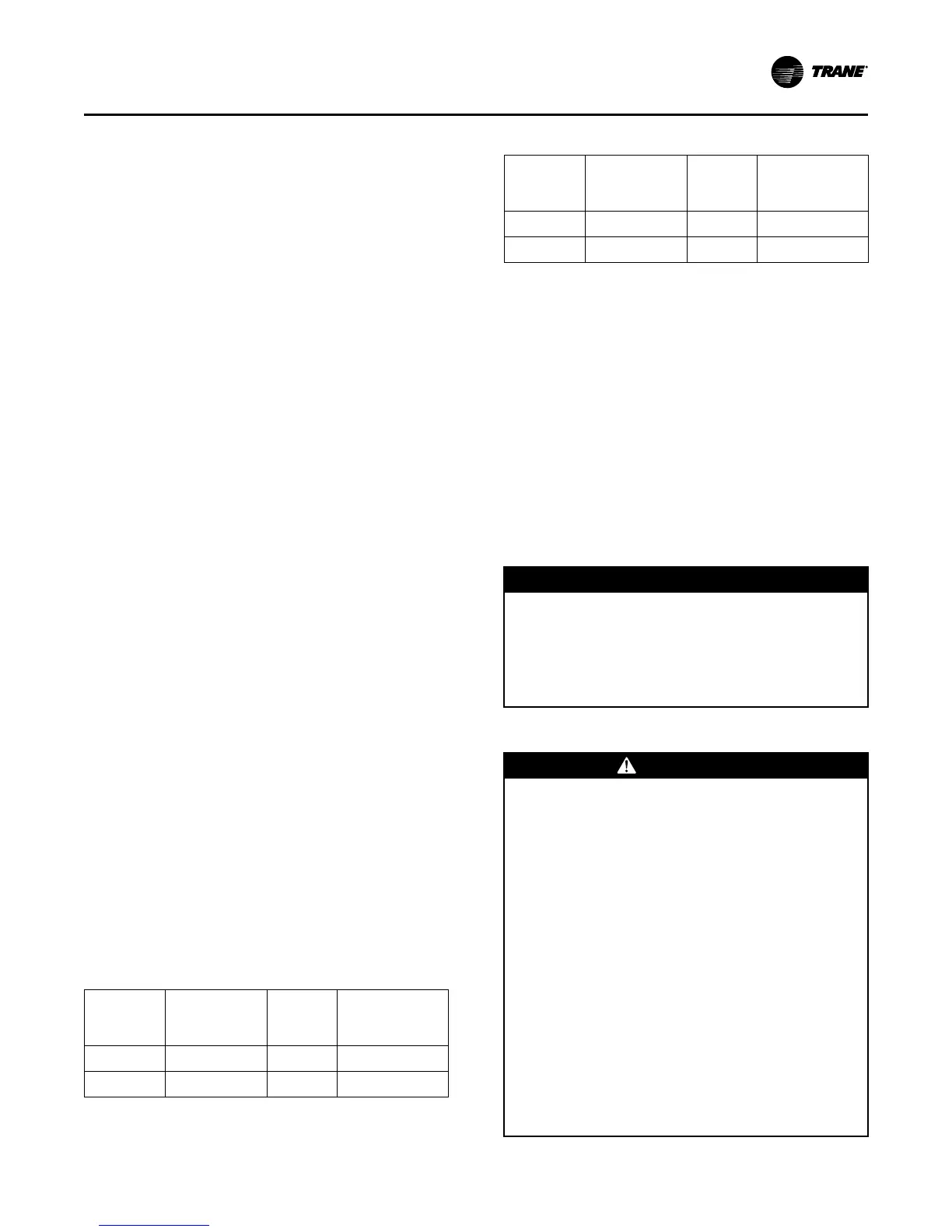

Table 12. Minimum vertical line velocities (continued)

Line Dia.

Minimum

Velocity

(fpm)

Line

Dia.

Minimum

Velocity (fpm)

1-3/8"

600

3-1/8"

915

1-5/8"

650

3-5/8"

975

Final Refrigerant Pipe Connections

To access the refrigerant pipe connections, remove the

louvered side grills. See connection drawings in

Dimensions and Weights chapter..

These condensing units are shipped with a Nitrogen

holding charge. Install pressure gauges to the

appropriate access valve(s) and take a reading.

• If no pressure is present, see Leak Testing

Procedure section.

• If pressure is present, relieve the pressure before

attempting to unsweat the “seal” caps.

• If refrigerant connections are not capped, but are

“spun-end” tubes, use a tubing cutter to remove

the end from the pipe.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

DDrriilllliinngg oorr ssaawwiinngg ppiippee ssttuubbss ccoouulldd iinnttrroodduuccee

ccooppppeerr cchhiippss iinnttoo tthhee ssyysstteemm aanndd ccaauussee eeqquuiippmmeenntt

ddaammaaggee..

DDoo nnoott ddrriillll aa hhoollee iinn tthhee sseeaall ccaappss oorr ssaaww tthhee eennddss

ooff ppiippee ssttuubbss..

Brazing Procedures

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn aanndd DDeeaaddllyy

GGaasseess!!

FFaaiilluurree ttoo ffoollllooww aallll pprrooppeerr ssaaffee rreeffrriiggeerraanntt

hhaannddlliinngg pprraaccttiicceess ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy..

NNeevveerr ssoollddeerr,, bbrraazzee oorr wweelldd oonn rreeffrriiggeerraanntt lliinneess oorr

aannyy uunniitt ccoommppoonneennttss tthhaatt aarree aabboovvee aattmmoosspphheerriicc

pprreessssuurree oorr wwhheerree rreeffrriiggeerraanntt mmaayy bbee pprreesseenntt..

AAllwwaayyss rreemmoovvee rreeffrriiggeerraanntt bbyy ffoolllloowwiinngg tthhee

gguuiiddeelliinneess eessttaabblliisshheedd bbyy tthhee EEPPAA FFeeddeerraall CClleeaann

AAiirr AAcctt oorr ootthheerr ssttaattee oorr llooccaall ccooddeess aass aapppprroopprriiaattee..

AAfftteerr rreeffrriiggeerraanntt rreemmoovvaall,, uussee ddrryy nniittrrooggeenn ttoo

bbrriinngg ssyysstteemm bbaacckk ttoo aattmmoosspphheerriicc pprreessssuurree bbeeffoorree

ooppeenniinngg ssyysstteemm ffoorr rreeppaaiirrss.. MMiixxttuurreess ooff

rreeffrriiggeerraannttss aanndd aaiirr uunnddeerr pprreessssuurree mmaayy bbeeccoommee

ccoommbbuussttiibbllee iinn tthhee pprreesseennccee ooff aann iiggnniittiioonn ssoouurrccee

lleeaaddiinngg ttoo aann eexxpplloossiioonn.. EExxcceessssiivvee hheeaatt ffrroomm

ssoollddeerriinngg,, bbrraazziinngg oorr wweellddiinngg wwiitthh rreeffrriiggeerraanntt

vvaappoorrss pprreesseenntt ccaann ffoorrmm hhiigghhllyy ttooxxiicc ggaasseess aanndd

eexxttrreemmeellyy ccoorrrroossiivvee aacciiddss..

IInnssttaallllaattiioonn MMeecchhaanniiccaall

Loading...

Loading...