CXRC-SVX01J-EN

13

Installation - Mechanical

Unit Handling Procedure

WWAARRNNIINNGG

IImmpprrooppeerr UUnniitt LLiifftt!!

FFaaiilluurree ttoo pprrooppeerrllyy lliifftt uunniitt iinn aa LLEEVVEELL ppoossiittiioonn

ccoouulldd rreessuulltt iinn uunniitt ddrrooppppiinngg aanndd ppoossssiibbllyy

ccrruusshhiinngg ooppeerraattoorr//tteecchhnniicciiaann wwhhiicchh ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy,, aanndd eeqquuiippmmeenntt oorr

pprrooppeerrttyy--oonnllyy ddaammaaggee..

TTeesstt lliifftt uunniitt aapppprrooxxiimmaatteellyy 2244 iinncchheess ((6611 ccmm)) ttoo

vveerriiffyy pprrooppeerr cceenntteerr ooff ggrraavviittyy lliifftt ppooiinntt.. TToo aavvooiidd

ddrrooppppiinngg ooff uunniitt,, rreeppoossiittiioonn lliiffttiinngg ppooiinntt iiff uunniitt iiss

nnoott lleevveell..

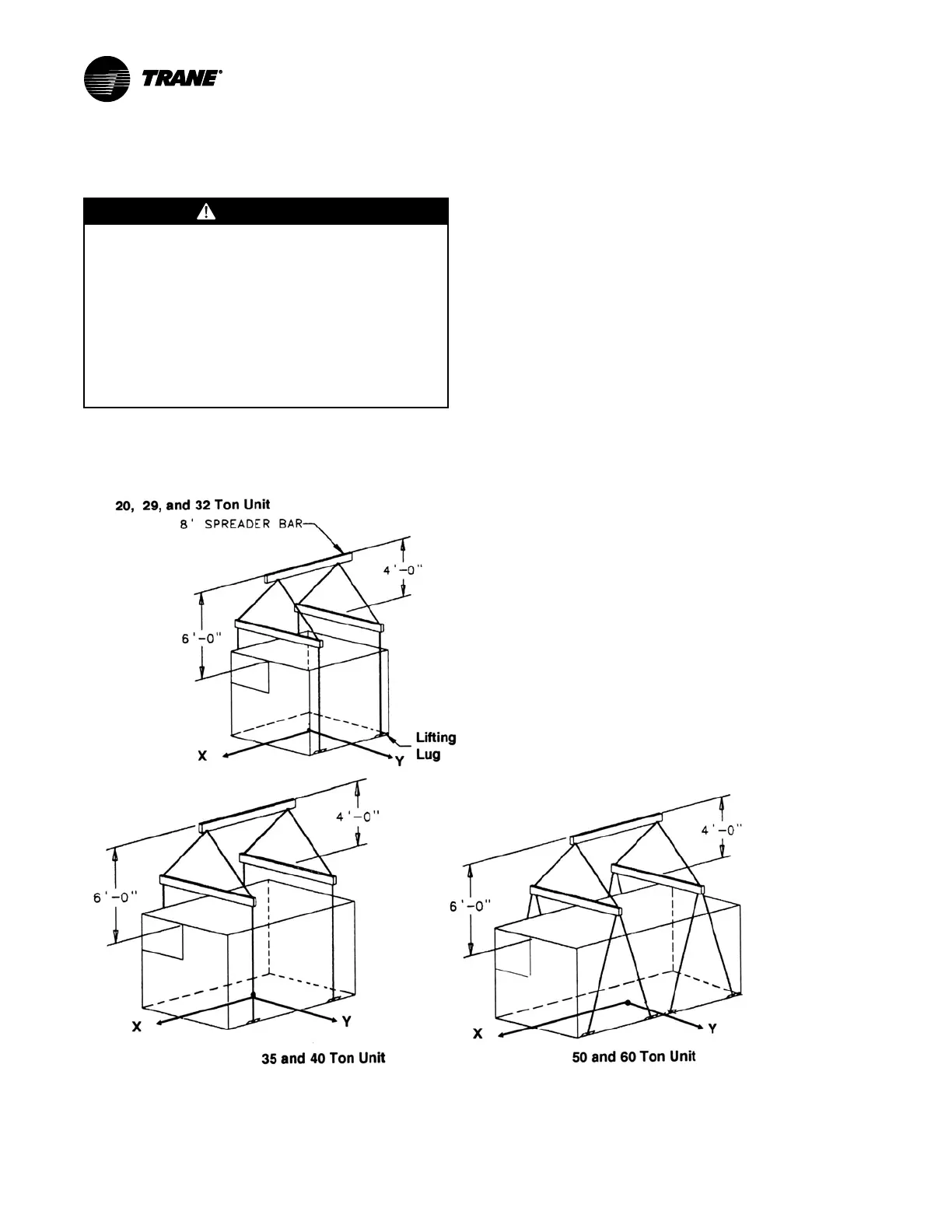

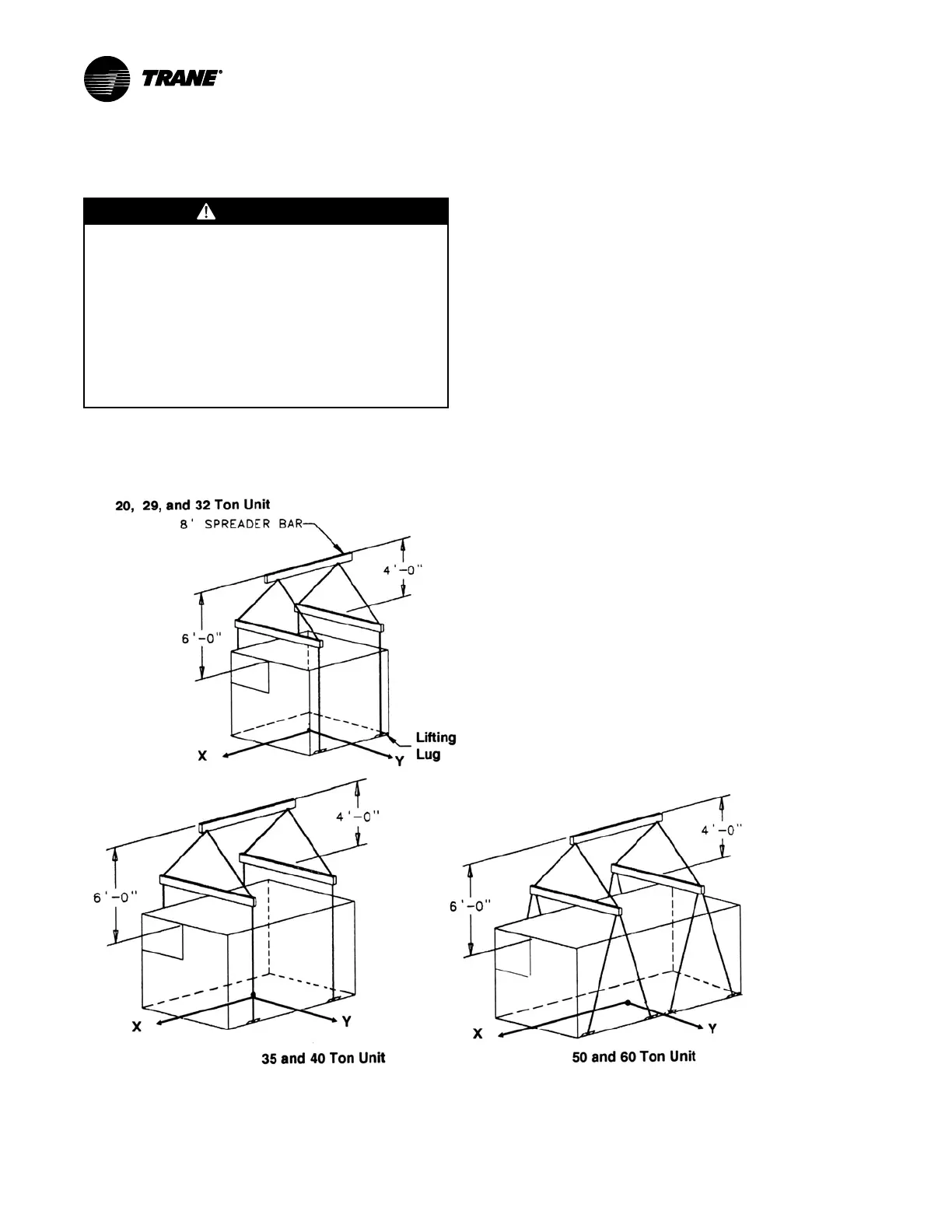

Lifting brackets are provided along the base rail on

both sides of the unit. Pass the lifting cables through

the 1.5-inch diameter holes in the brackets and install

spreader bars between the cables above unit. A label

on the unit base rail illustrates proper lifting procedure.

When rigged properly, the unit will balance at its center

of gravity.

Perform a test lift to ensure balance, equilibrium, and

unit levelness is maintained. Adjust rigging as required

based on initial test lift. Test adjusted rigging with

second test lift. Continue test lifting unit until

satisfactory results are obtained. Do not proceed with

final lift until the unit remains static, level and stable

during test lift. See Figure 11, p. 13.

NNoottee:: Maintain unit level throughout the lifting process

or structural damage may occur.

Figure 11. Proper Unit Rigging and Lifting Procedure Using Spreader Bars

Loading...

Loading...