32

CVHE-SVN04M-EN

13. Reinstall all other chiller components which were

removed. Reconnect the inlet vane linkages.

14. Torque all bolts to specifications listed in Table 13,

p. 32.

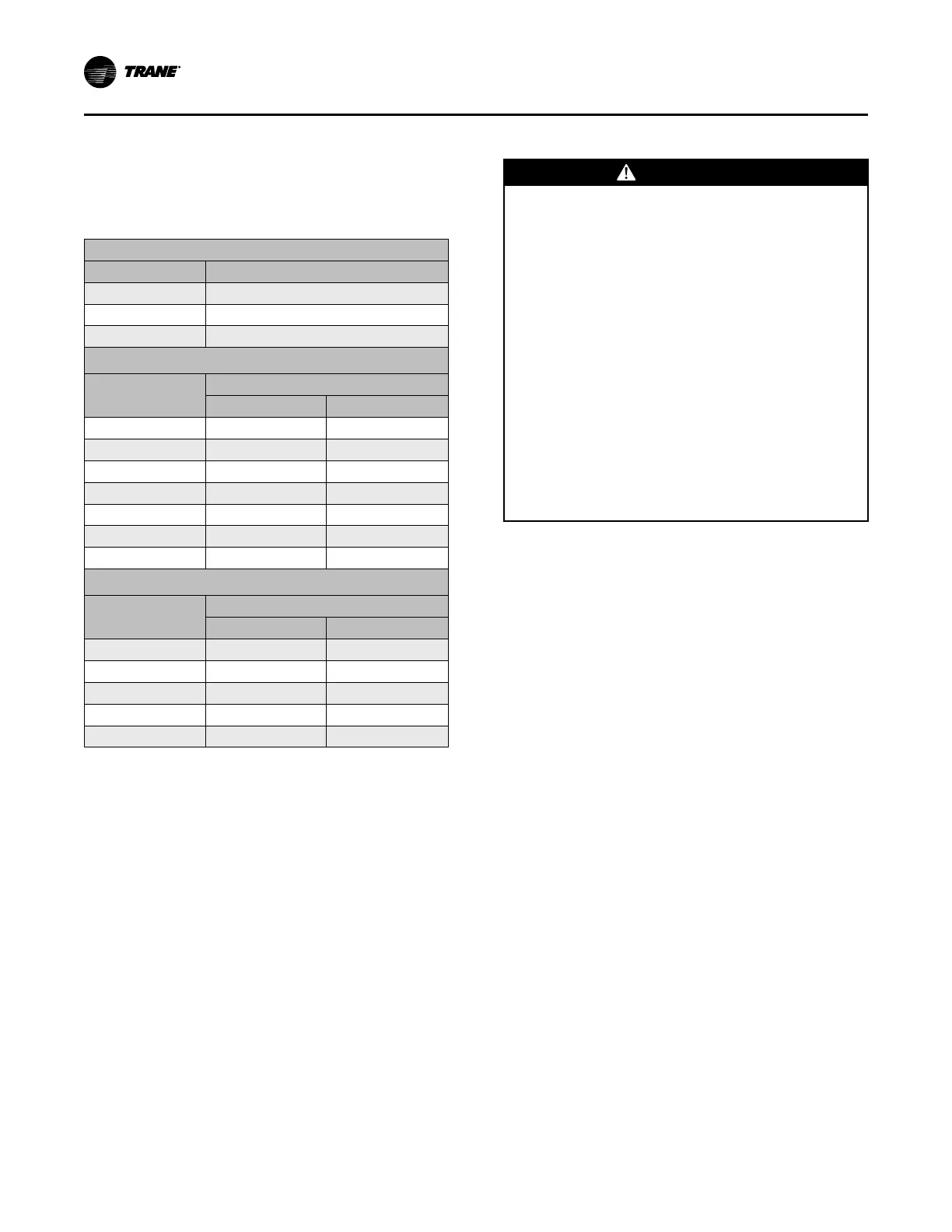

Table 13. Bolt torques

Non-gasket Joints Bolt Torques

Bolt Size (in) Torque (ft·lb)

1/2

70

5/8

150

3/4

250

All Other Metal Joints (O-Ring Joins) Shall Use the Following

Torques

Bolt Size (in)

Torque (ft·lb)

Min. Max

1/4

5 7

5/16

11 15

3/8

22 27

1/2

55 75

5/8

120 165

3/4

200 280

1 400 550

All Joints with Flat Elastomeric Gaskets Shall Use the Following

Bolt Torque

Bolt Size (in)

Torque (ft·lb)

Min. Max

5/16

8 12

3/8

12 18

1/2

33 50

5/8

70 90

3/4

105 155

15. Reconnect the previously cut compressor/motor oil

supply and return lines and the motor cooling lines

using the factory-supplied couplings.

Brazing

WWAARRNNIINNGG

EExxpplloossiioonn HHaazzaarrdd aanndd DDeeaaddllyy GGaasseess!!

FFaaiilluurree ttoo ffoollllooww aallll pprrooppeerr ssaaffee rreeffrriiggeerraanntt

hhaannddlliinngg pprraaccttiicceess ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy..

NNeevveerr ssoollddeerr,, bbrraazzee oorr wweelldd oonn rreeffrriiggeerraanntt lliinneess oorr

aannyy uunniitt ccoommppoonneennttss tthhaatt aarree aabboovvee aattmmoosspphheerriicc

pprreessssuurree oorr wwhheerree rreeffrriiggeerraanntt mmaayy bbee pprreesseenntt..

AAllwwaayyss rreemmoovvee rreeffrriiggeerraanntt bbyy ffoolllloowwiinngg tthhee

gguuiiddeelliinneess eessttaabblliisshheedd bbyy tthhee EEPPAA FFeeddeerraall CClleeaann

AAiirr AAcctt oorr ootthheerr ssttaattee oorr llooccaall ccooddeess aass aapppprroopprriiaattee..

AAfftteerr rreeffrriiggeerraanntt rreemmoovvaall,, uussee ddrryy nniittrrooggeenn ttoo

bbrriinngg ssyysstteemm bbaacckk ttoo aattmmoosspphheerriicc pprreessssuurree bbeeffoorree

ooppeenniinngg ssyysstteemm ffoorr rreeppaaiirrss.. MMiixxttuurreess ooff

rreeffrriiggeerraannttss aanndd aaiirr uunnddeerr pprreessssuurree mmaayy bbeeccoommee

ccoommbbuussttiibbllee iinn tthhee pprreesseennccee ooff aann iiggnniittiioonn ssoouurrccee

lleeaaddiinngg ttoo aann eexxpplloossiioonn.. EExxcceessssiivvee hheeaatt ffrroomm

ssoollddeerriinngg,, bbrraazziinngg oorr wweellddiinngg wwiitthh rreeffrriiggeerraanntt

vvaappoorrss pprreesseenntt ccaann ffoorrmm hhiigghhllyy ttooxxiicc ggaasseess aanndd

eexxttrreemmeellyy ccoorrrroossiivvee aacciiddss..

Except as noted in the following, braze with the

following filler metals:

• Braze all copper-to-copper joints with A.W.S. BcuP-

6 filler metal.

• Braze all copper-to-brass joints with A.W.S. BcuP-6

filler metal using white or black brazing flux.

• Braze all other joints with A.W.S. Bag-28 filler

metal.

Bleed dry nitrogen through the lines while brazing to

prevent the formation of oxides which can contaminate

the oil and refrigerant systems.

NNoottee:: Use silver soldering with 96% Sn-4% Ag (for

example, J.W. Harris Co. Stay Brite

®

) to replace

brazing when the heat from brazing would be

detrimental to the immediate or nearby parts.

EExxaammpplleess::

1. Joints next to threaded joints in which the copper

or brass threads become too soft and/or Loctite®

loses its sealing capability due to excess heat.

2. Joints next to valves in which the valves cannot be

taken apart or are not recommended for brazing.

Final Installation Procedures

After the chiller has been moved to the equipment

room and reassembled under Trane supervision, leak

testing, and evacuation can be performed by Trane or

under Trane supervision. Upon verification of leak

tightness, installation can proceed for unit piping,

wiring, etc. After installation has been completed, fill

out CTV-ADF001*-EN (CenTraVac

™

Installation

Completion Check Sheet and Request for Trane

Service) to schedule the startup; the chiller

RReeaasssseemmbbllyy

Loading...

Loading...