CG-SVX027E-GB

20

4 UNT-PRC002-GB

Technical Data

FWD 08 12 20 30 45

Power supply (V/Ph/Hz) 230/1/50

Capacities

Cooling capacity on water (1) (kW) 5,2 8,3 15 18,8 30,1

Heating capacity on water (2) (kW) 6,3 11,9 18,9 20,9 38,2

Fan motor (type) 2 x direct drive centrifugal

Fan power input (3) (kW) 0,23 0,46 0,65 1,04 1,51

Current amps (3) (A) 1,1 2,2 3,1 4,7 5,5

Start-up amps (A) 3,2 5,5 9,3 14,1 16,5

Air flow

minimum (m

3

/h) 490 980 1400 1800 2700

nominal (m

3

/h) 820 1650 2300 3000 4500

maximum (m

3

/h) 980 1970 2600 3600 5400

Main coil

Water entering/leaving connections (type) ISO R7 rotating female

(Dia) 3/4" 3/4" 1 1/2" 1 1/2" 1 1/2"

Electric heater (accessory for blower only)

Electric power supply (V/Ph/Hz) 230/1/50 230/1/50 or 400/3/50 400/3/50 400/3/50 400/3/50

Heating capacity (kW) 2/4 8 10 12 12

Hot water coil (accessory for blower only)

Heating capacity (4) (kW) 6,3 12 17,4 22,4 34,5

G2 filter (filter box accessory)

Quantity 2 2 2 2 2

Dimensions ( LxWxth) (mm) 386x221x8 486x271x8 586x321x8 586*421*8 586*621*8

G4 filter (filter box accessory)

Quantity - 2 2 2 2

Dimensions ( LxWxth) (mm) - 486x264x48 586x314x48 586*414*48 586*614*48

Condensate pump (accessory) (type) Centrifugal

Water flow - lift height (l/h - mm) 24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5) (dB(A)) 36/40/43 38/41/44 46/50/53 47/52/57 47/52/58

Sound power level (5) (dB(A)) 46/50/53 48/51/54 56/60/63 57/62/67 57/62/68

Unit dimensions

Width x Depth (mm) 890 x 600 1090 x 710 1290 x 820 1290 x 970 1290 x 1090

Height (mm) 250 300 350 450 650

Shipped unit dimensions

Width x Depth (mm) 933 x 644 1133 x 754 1333 x 864 1333 x 1008 1333*1133

Height (mm) 260 310 360 460 660

Weight (kg) 32 46 61 76 118

Colour galvanised steel

Recommended fuse size

Unit alone (aM/gI) (A) 8/16 8/16 8/16 8/25 8/25

Unit with electric heater (gI) (A) 16 (2kW),25 (4kW) 40 (230V),3*16 (400V) 3*20 3*25 3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

Installation – Mechanical

Drainage

Locate the unit near a large capacity drain for water

vessel draindown during shutdown or repair. Water

piping is provided with drain connections. Refer to

“Water Piping.” All local and national codes apply.

Piping

A vent is provided on the top of the evaporator at the

return end. Be sure to provide additional vents at high

points in the piping to bleed air from the chilled water

system. Install necessary pressure gauges to monitor the

entering and leaving chilled water pressures.

Provide shutoff valves in lines to the gauges to isolate

them from the system when they are not in use. Use

rubber vibration eliminators to prevent vibration

transmission through the water lines. If desired, install

thermometers in the lines to monitor entering and

leaving water temperatures. Install a balancing valve

in the leaving water line to control water ow balance.

Install shutoff valves on both the entering and leaving

water lines so that the evaporator can be isolated

for service. Make sure the water circuit includes all

devices and controls used to provide proper water

system operation and unit operating safety. Refer to the

appropriate sections in the unit manual (Addendum_

PROD-SVX01) for Installation, appropriate procedures,

component specications and safety instructions.

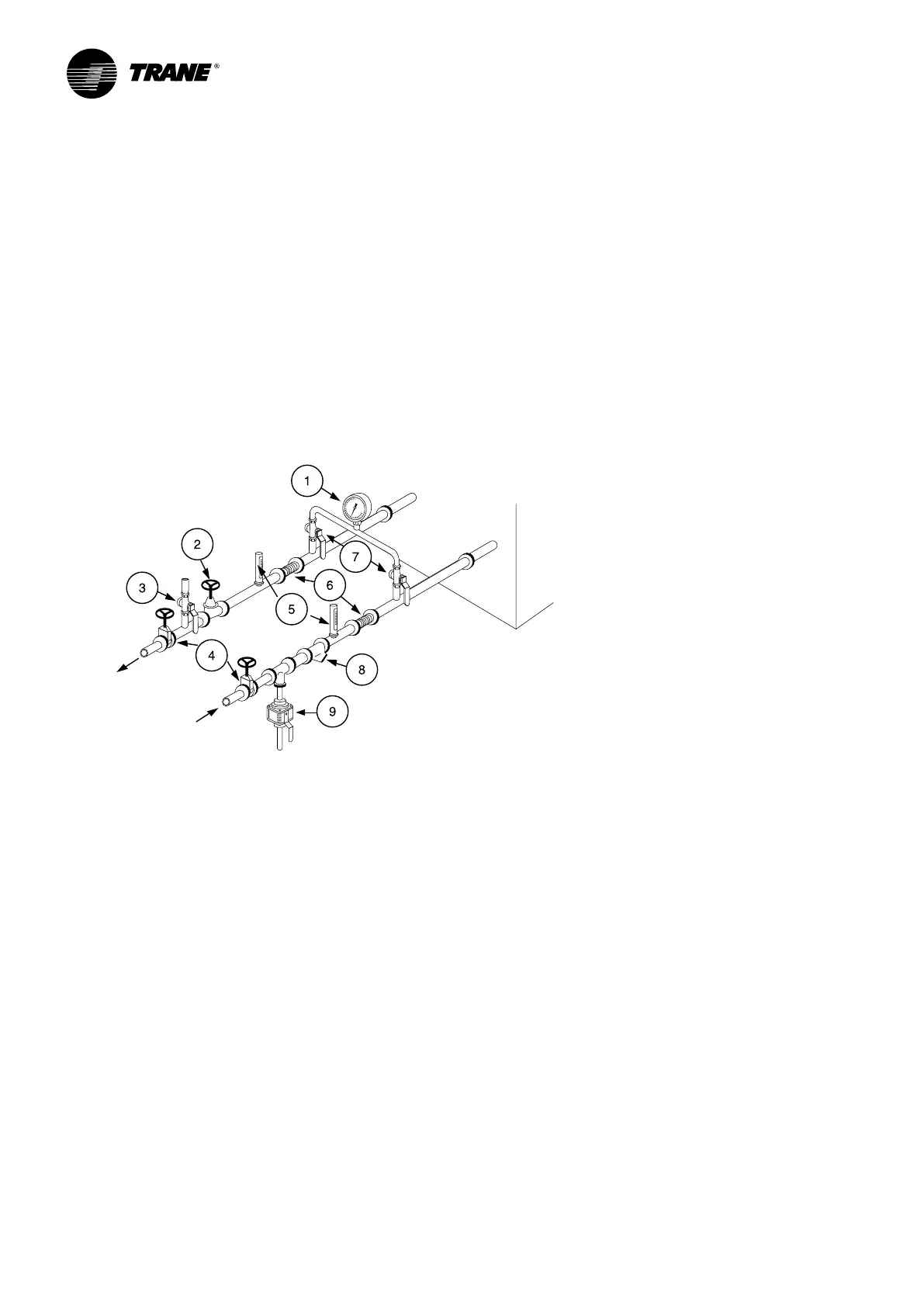

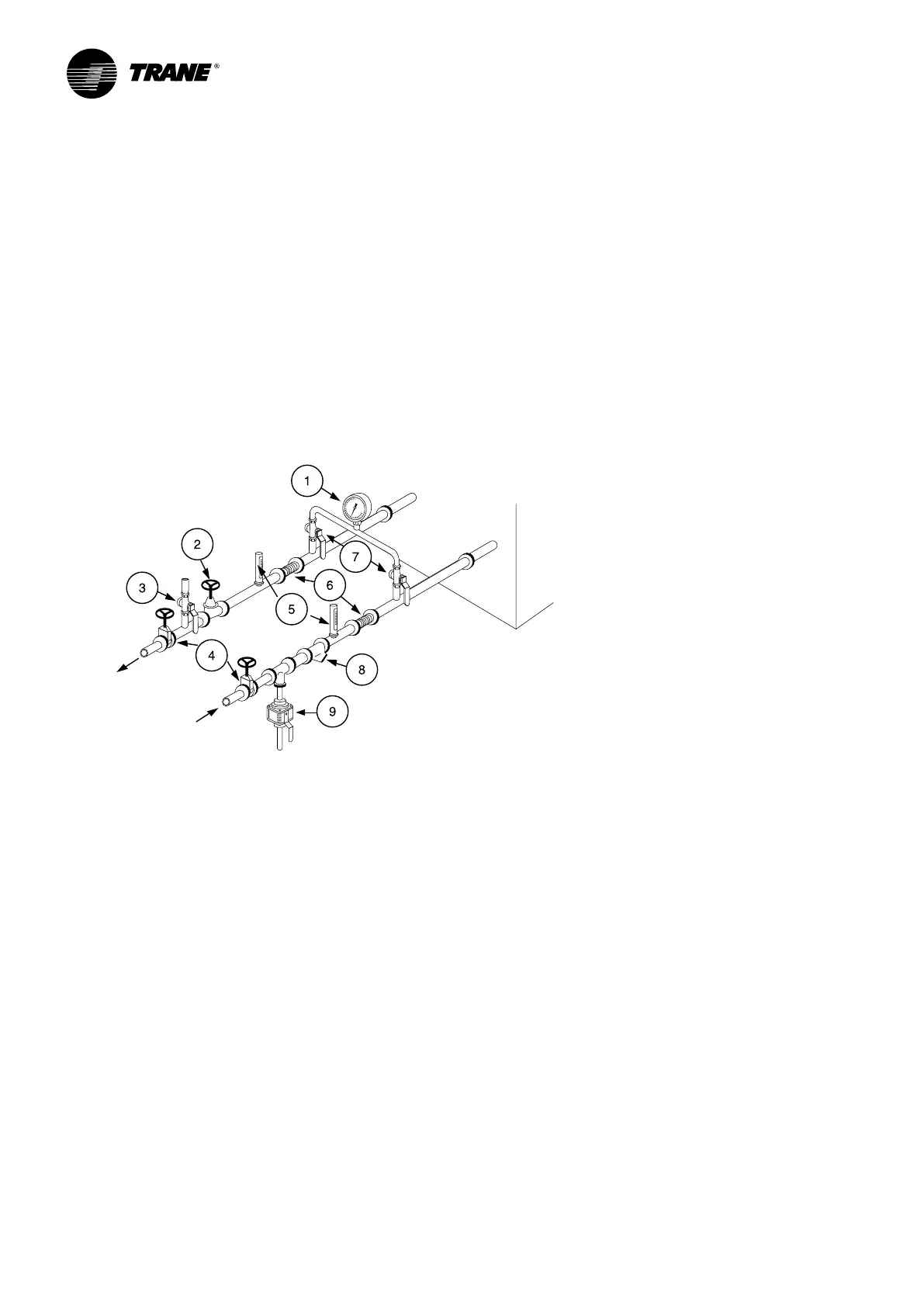

Figure 3 - Unit typical water circuit

1 = Pressure gauges: show entering and leaving water

pressure

2 = Balancing valve: adjusts water ow.

3 = Air purge allows to remove the air from the water

circuit during ll up.

4 = Stop valves: isolate chillers and water circuiting

pump during maintenance operations.

5 = Thermometers: indicate chilled water entering and

leaving temperatures.

6 = Expansion compensators: avoid mechanical stress

between chiller and piping installation.

7 = Stop valve located on the outlet connection: used

to measure the water pressure inlet or outlet of

evaporator.

8 = Strainer: avoid to get heat exchangers dirty. All

installation must be equipped with efcient strainer

in order that only clean water enters into exchanger.

If there is no strainer, reserve will be formulated by

the Trane technician at the start-up of the unit. The

trainer used must be able to stop all particles with a

diameter greater than 1 mm.

9 = Draining: used as the draining the plate heat

exchanger.

10 = Do not start the unit with low water volume or not

enough pressurized circuit.

Note: A pressure switch device to detect lack of water

is not included in the pump package. Installation of this

type of device is highly recommended to avoid sealing

damage due to operation of pump without enough

water.

Minimal installation water content

The water volume is an important parameter because

it allows as table chilled water temperature and avoids

short cycle operation of the compressors.

Parameters which influence the water temperature

stability

• Water loop volume

• Load uctuation

• Number of capacity steps

• Compressors rotation

• Dead band (adjusted on chiller controller)

• Minimum time between 2 starts of a compressor

Minimum water volume for a comfort application

For comfort application we can allow water temperature

uctuation at part load. The parameter to take

into account is the minimum operating time of the

compressor. In order to avoid lubrication problem

on a scroll compressor it must run at least 2 minutes

120 seconds) before it stops.

Loading...

Loading...