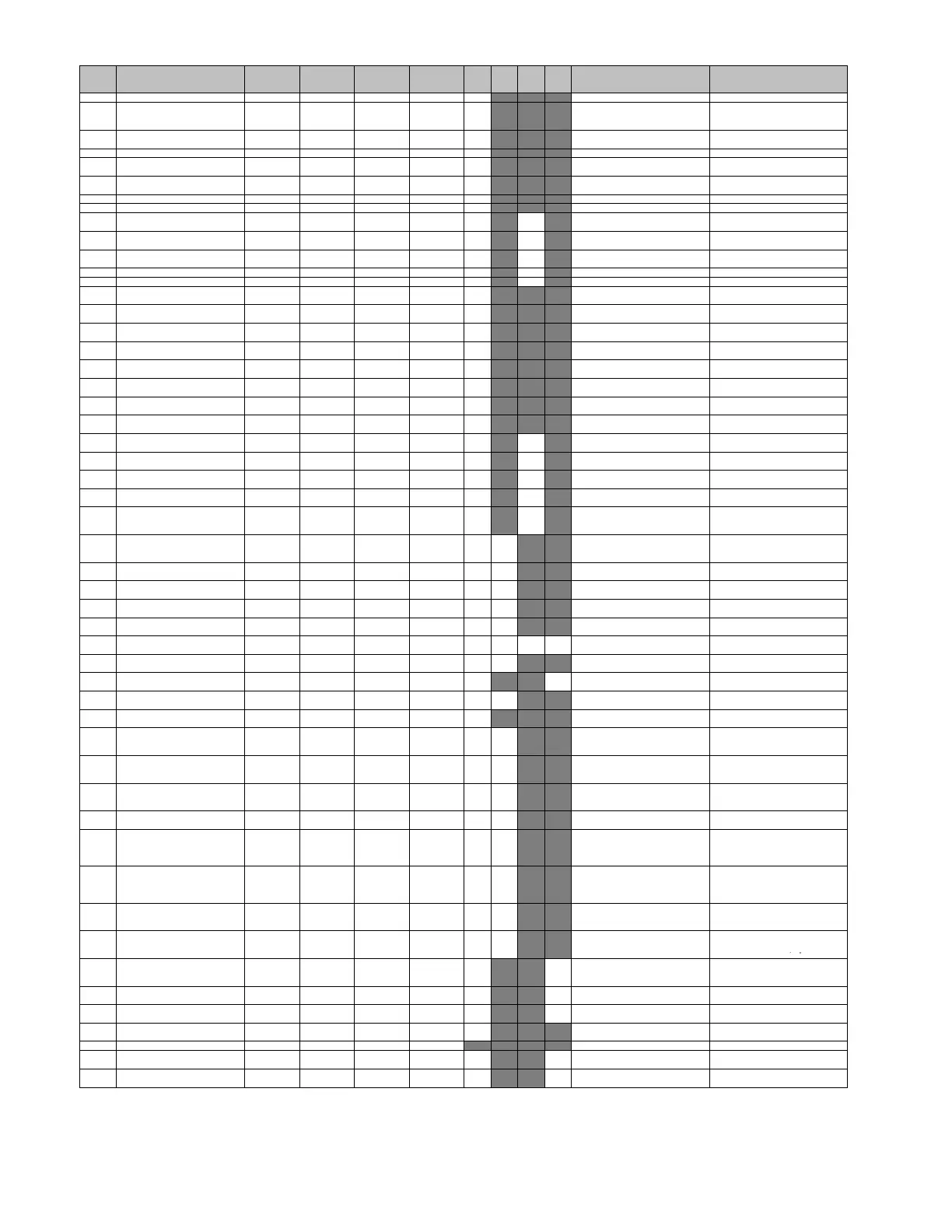

TAM822

ALERT CODES FOR *AM8

Alert

Code

Alert Group

Display

Assembly Text

A/TCONT900 A/TZONE 950

Notification

Level

AFC

Fault

Code

EVC

Fault

Code

EHC

Fault

Code

HHC

Fault

Code

Alert Description Possible Cause

18 Control failure CNTRL FLT ERR18 ERR 18.0 Critical

ON

Internal Control Error Control fault, replace AFC

19 Twinning fault TWIN ERR ERR19 ERR 19.0 Information 8 Air handler twinning error

More than one ID unit connected on the

communicating bus is not allowed

52 Indoor air sensor error ICAS OPEN N/A N/A Information 6 Indoor air sensor is open Sensor open, unplugged, wiring harness

52 Indoor air sensor error ICAS SHORT N/A N/A Information

6

Indoor air sensor is shorte

Sensor shorted, wiring harness

90 Communication busy fault SYS COM CRC N/A N/A Information 3 Excessive communication errors R & B to thermostat reversed polarity

91 Communication inactive fault

SYS COMM

ERR

ERR91 ERR 91.02 Critical 3 Loss of Heat/Cool demand message

Open / Shorted data line / CCM

communication erro

91 Communication inactive fault NO SYS CLK ERR91 ERR 91.03 Critical

3

Loss of Bit Master Control fault, replace AFC

92 Fuse failure CHECK FUSE N/A N/A Critical

1*

24V fuse open error 24VAC circuit short

104 Heater relay fault

EH RLY

OPEN#

ERR104 ERR 104.0 User Display 12 2 Heater relay stuck open error Heater relay failure

104 Heater relay fault ALL RLY OPEN ERR104 ERR 104.02 Critical 12 2 All heater relay stuck open error Heater relay failure

104 Heater relay fault

EK RLY

WELD#

ERR104 ERR 104.01 Critical 12 3 Heater Relay Stuck Closed Error

Heater relay failure, open element, open

non cycling limit switch

105 Heater interlock rela

faul

BL INTLK OP ERR105 ERR 105.0 User Dis

la

12 8

Interlock Rela

Stuck O

en Erro

Blower interlock rela

failur

105 Heater interlock rela

faul

BL INTLK CL ERR105 ERR 105.01 User Dis

la

12 8

Interlock Rela

Stuck Closed Erro

Blower interlock rela

failur

106 External shutdown fault EXT SW OPEN ERR106 ERR 106.0 User Display 1 External shutdown input open error External float switch, other device open

114 PM bad or missing fault PM DATA ERR N/A N/A Information 2 PM data corrupt (Operation allowed) PM error

114 ID motor error ID MTR ERR ERR114 ERR 114.02 User Display 2

Motor HP is < than PM value (Operation

not allowed)

Incorrect VS motor or PM installed

114 PM bad or missing fault PM MISSING ERR114 ERR 114.03 Critical 2

PM missing with good local copy

(Operation allowed

PM error

114 PM bad or missing fault PM UNIT ERR N/A N/A Information 2

Bad data in PM with good local copy

O

eration allowed

PM error

114 PM bad or missing fault PM MEM ERR ERR114 ERR 114.05 Critical 2

Bad data in PM with no local copy

O

eration allowed

PM error

114 PM bad or missing fault PM MISSING ERR114 ERR 114.06 Critical 2

PM missing with no local copy (Operation

not allowed

PM error

114 ID motor error MTR PWR HI ERR114 ERR 114.07 User Display 2

Motor HP is > than PM value (Operation

allowed)

Incorrect VS motor or PM installed

123 Demand configuration fault EH CONFIG ERR123 ERR 123.0 User Display 12 6 Electric heat configuration rrror

KW jumper position on PARK

(replacement control only)

152 Heater element fault

EH ELMNT

OP#

ERR152 ERR 152.0 User Display 12 4 Heater element open Low airflow, dirty coil/filter

153 Thermal limit switch fault EH CTCO TRIP ERR153 ERR 153.0 User Display 12 5 Cycling thermal cut-out trip has occurred Low airflow, dirty coil/filter

154 EH airflow limit fault EH OFF/NO AF ERR154 ERR 154.0 Critical 12 7

Electric heat control locked out because of

insufficient airflo

EHC locked out

154 EH airflow limit fault EH LIM/NO AF ERR154 ERR 154.1 User Display 12 7

Electric heat control is under restricted

operation because of insufficient airflow

Heater-Air handler mismatch

155

Indoor electronic expansion valve

motor fault

EEV MTR ERR ERR155 ERR 155.0 User Display 11 5

EEV motor fault has been detected for 8

consecutive times and valve is locked out

Faulty EEV motor / wiring harness

155

Indoor electronic expansion valve

motor fault

EEV MTR ERR ERR155 ERR 155.01 User Display 11 1

EEV electric motor current indicates open

or short

Faulty EEV motor / wiring harness

156 System low on charge fault

SYSTEM1

ERR

ERR156 ERR 156.0 User Display 11 7 System 1 - High superheat

System low on charge, liquid line

restriction

ET/GT sensor calibratio

157 Condensate fault

CONDESAT

FL

ERR157 ERR 157.0 Critical 11 11 Condensate overflow condition detected Condensate line clogged

158 Coil freeze fault ID COIL FRST ERR158 ERR 158.0 User Display 11 13 Indoor coil freeze condition detected

Low / incorrect airflow, low refirgerant

char

e

ET sensor calibratio

159 Unit Bus fault

AFC COMM

ERR

ERR159 ERR 159.0 Critical 5 14 1 1 AFC communication error

Wire harness between AFC and

distribution board

159 Unit Bus fault

EHC COMM

ERR

ERR159 ERR 159.01 User Display 5 1 EHC communication error

Wire harness between EHC and

distribution board

159 Unit Bus fault

HHC COMM

ERR

ERR159 ERR 159.02 User Display 5 1 HHC communication error

Wire harness between HHC and

distribution board

159 Unit Bus fault

EVC COMM

ERR

ERR159 ERR 159.03 User Display 5 14 EVC communication error

Wire harness between EVC and

distribution board

159 Unit Bus fault

CDA COMM

ERR

ERR159 ERR 159.04 Information 5 Display Assembly communication error

Wire harness between Display Assembly

and distribution board

160 Indoor EEV control configuration error CONFIG FLT ERR160 ERR 160.0 User Display 11 15

Configuration group index or evap

temperature sensor type are not

confi

ured

PM programming or internal

communication error

161 Evaporator temperature sensor fault ET SEN ERR ERR161 ERR 161.0 User Display 11 3

Indoor coil temperature sensor reading is

out of range, indicates open or short

Sensor open / shorted, unplugged, wiring

harness problem

161 Gas temperature sensor fault GT SEN ERR ERR161 ERR 161.01 User Display 11 4

Indoor coil temperature sensor reading is

out of range, indicates open or short

Sensor open / shorted, unplugged, wiring

harness problem

163 Indoor EEV control fault EEV CNTL FLT ERR163 ERR 163.0 User Display 11 2

EEV electric motor drive or feedback or 12

V failure detected

EEV motor drive or motor feedback or 12v

failure

164 Indoor EEV fault

EEV CLSE

ERR

ERR164 ERR 164.0 User Display 11 6

EEV migrated to 'Close' position but

superheat is not at the desired set point,

valve is not responding to a change in

osition

Possible stuck valve, ET/GT sensor

calibration

164 Indoor electronic expansionvValve fault

EEV OPEN

ERR

ERR164 ERR 164.01 User Display 11 6

EEV migrated to 'Open' position but

superheat is not at the desired set point,

valve is not responding to a change in

osition

Possible stuck valve, ET/GT sensor

calibration

166 Superheat is flooding fault SYSTEM4 ERR ERR166 ERR 166.0 User Display 11 10 System 4 - Low superheat

Stuck valve, ET/GT sensor calibration,

restricted distributor line that ET is

connected to

167

Indoor electronic expansion valve

control is not controlling because

outdoor status is unknown

OD DATA MISS ERR167 ERR 167.0 User Display 11 16 OD status unknown to EVC

If Comm LED on OD unit is flashing the

correct device count, replace AFC

out

oor status

s un

now

168

Indoor heat demand is not available to

hydronic heat control

HH FAULT ERR168 ERR 168.0 User Display 12 6

Hydronic Heat is not controlling because

Indoor heat demand is not received

If Unit LED on HHC is flashing once every

four seconds, replace HHC

169

Hydronic heat control configuration

fault

HH CONFIG ERR169 ERR 169.0 User Display 12 5

Hydronic heat capacity is unknown to

h

dronic heat control

Dip switch on HHC not set (replacement

control onl

170

Hydronic heat control freeze condition

detected

HH FRZ DET ERR170 ERR 170.0 User Display 12 2 Hydronic heat coil freeze detected

Hydronic coil freeze inlet temperature

sensor reading is less than 38ºF

171 Communication inactive fault

BLW COMM

ERR

ERR171 ERR 171.0 Critical 4* Blower Communication is not detected Faulty wiring harness, VS motor

172 Display Assembly stuck key KEY FAULT ERR172 ERR 172.0 User Display Display Assembly has a stuck key Faulty Display Assembly

173

Open coil freeze sensor (hydronic heat

onl

HH FRZ OPEN ERR173 ERR 173.01 User Display 12 4

Hydronic coil freeze inlet temperature

sensor o

en condition detecte

Sensor open, unplugged, wiring harness

o

en

173

Shorted coil freeze sensor (hydronic

heat onl

HH FRZ

SHORT

ERR173 ERR 173.0 User Display 12 3

Hydronic coil freeze inlet temperature

sensor short condition detecte

Sensor short, wiring harness shorted

Notes:

1. * AFC STATUS LED will be solid ON during this fault•

2. COMM LED (amber) will flash the number of communicating devices connecte

3. BM LED should be ON Solid when power is applied

4. STATUS LED will flash once per second in Idle mode.

Once a thermostat demand is received, it will flash 1 time/100 CFM requested

5. UNIT LED (blue) will flash once every four seconds when communications are norma

Loading...

Loading...