182 RT-SVX36G-EN

Maintenance

Electrical Phasing:

If it becomes necessary to replace a compressor, it is very important to review and follow the

Electrical Phasing procedure described in the startup procedure of the IOM.

If the compressors are allowed to run backward for even a very short period of time, internal

compressor damage may occur and compressor life may be reduced. If allowed to run backwards

for an extended period of time the motor windings can overheat and cause the motor winding

thermostats to open. This will cause a “compressor trip” diagnostic and stop the compressor

If a scroll compressor is rotating backwards, it will not pump and a loud rattling sound can be

observed. Check the electrical phasing at the compressor terminal box. If the phasing is correct,

before condemning the compressor, interchange any two leads to check the internal motor

phasing.

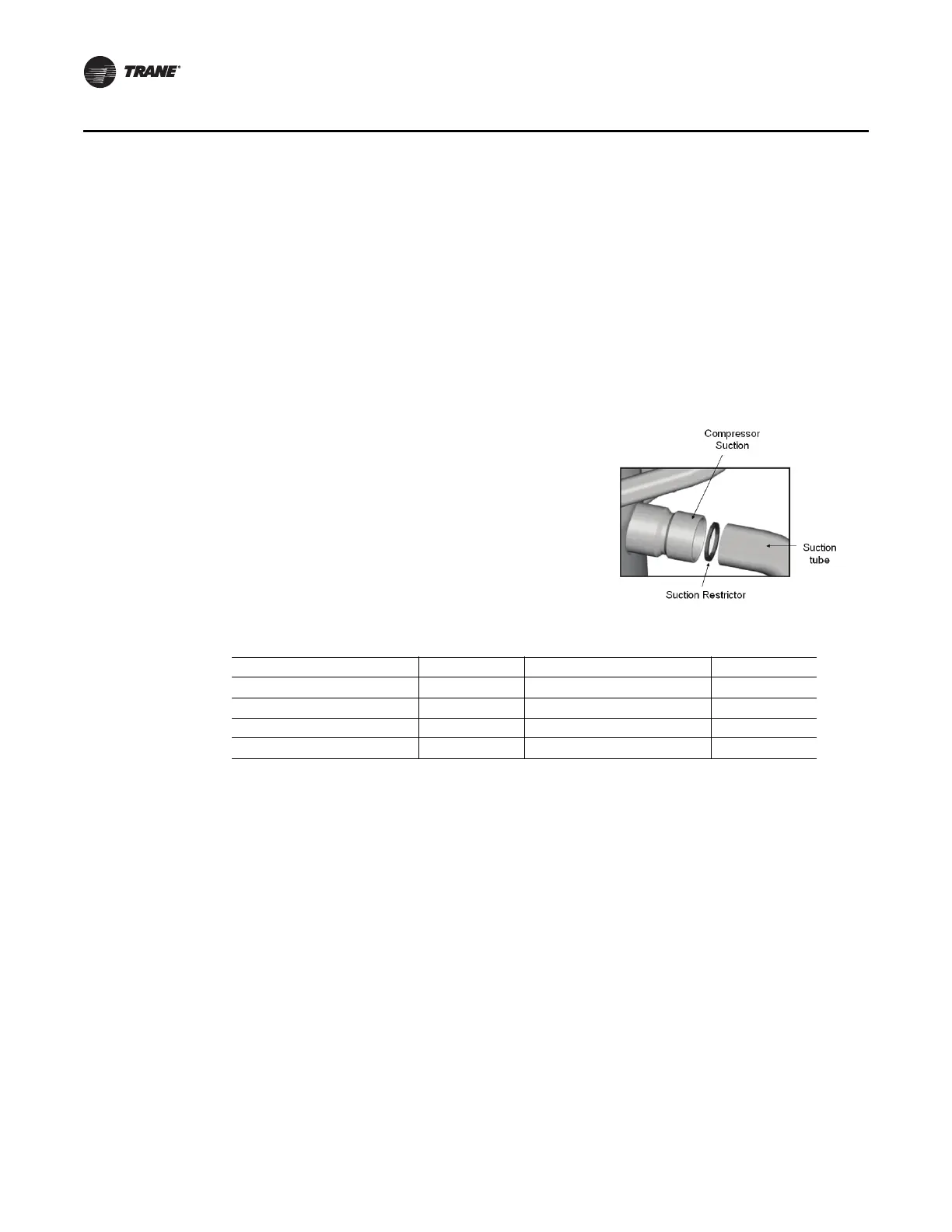

Precision Suction Restrictor:

Tandem manifold compressors that have unequal

capacity sizes utilize a precision suction restrictor to

balance the oil levels in the compressors. For tandem

manifold compressors in Intellipak units, this restrictor

is placed in the compressor indicated in Tab l e 6 8 .

When replacing this compressor, it is imperative that

the proper restrictor is selected from those provided

with the replacement compressor.

When the compressors are restarted verify that correct

oil levels are obtained with both compressors

operating.

Figure 95. Precision suction restrictor

Table 68. Suction restrictor location (AC/EC)

25 Ton Standard Capacity CSHD125 60 Ton Standard Capacity CSHD142

25 & 29 Ton High Capacity CSHD125 75 Ton Standard Capacity CSHN176

30 & 36 Ton High Capacity CSHD161 75 & 89 Ton High Capacity CSHN184

40 Ton Standard Capacity CSHD110 105 Ton High Capacity CSHN250

50 Ton Standard Capacity CSHD120 115 Ton High Capacity CSHN250

Loading...

Loading...