38

PKGP-SVX03D-EN

Troubleshooting and Diagnostics

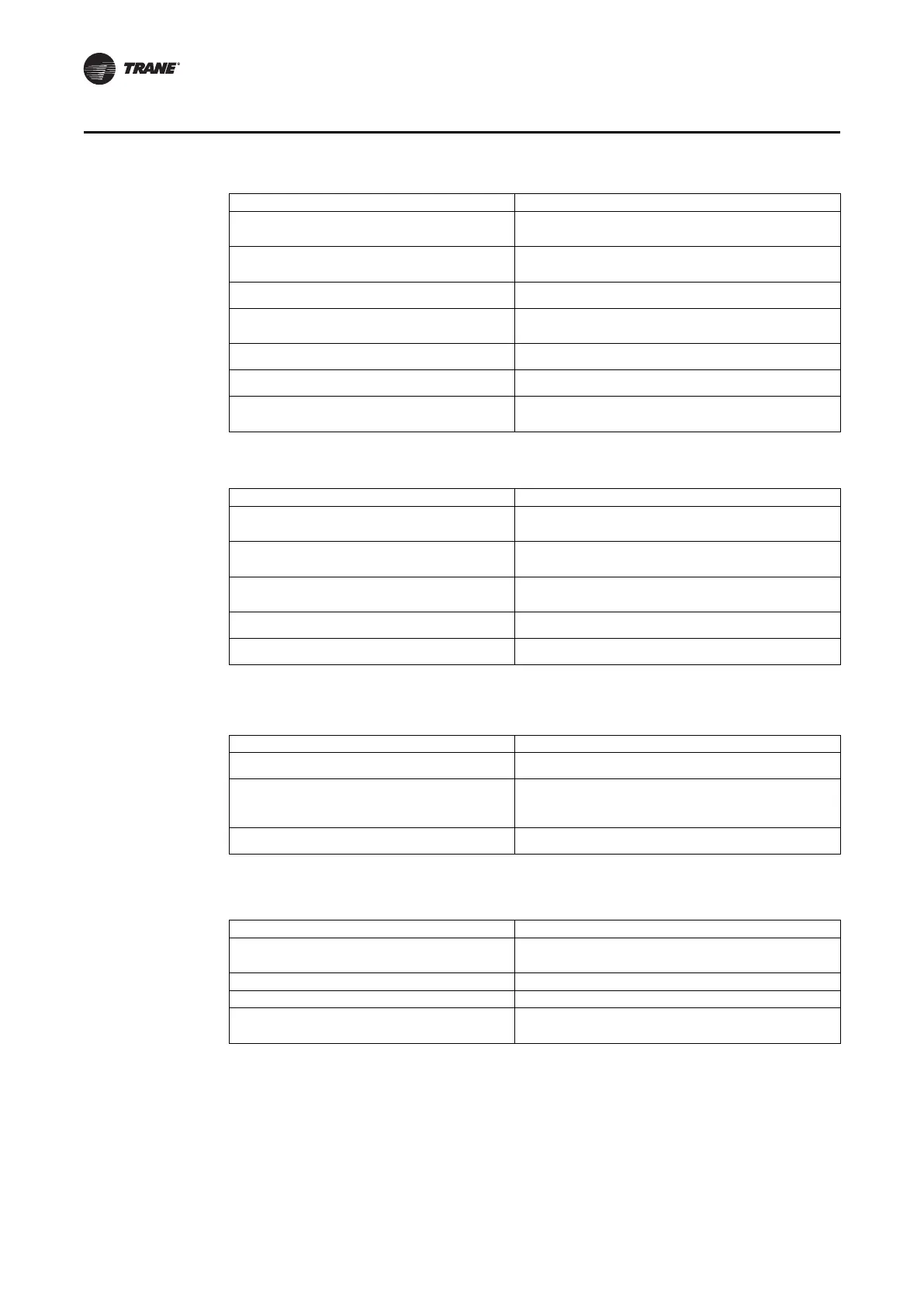

H. Inadequate air cooling capacity

I. Too low suction pressure

J. Too high suction pressure

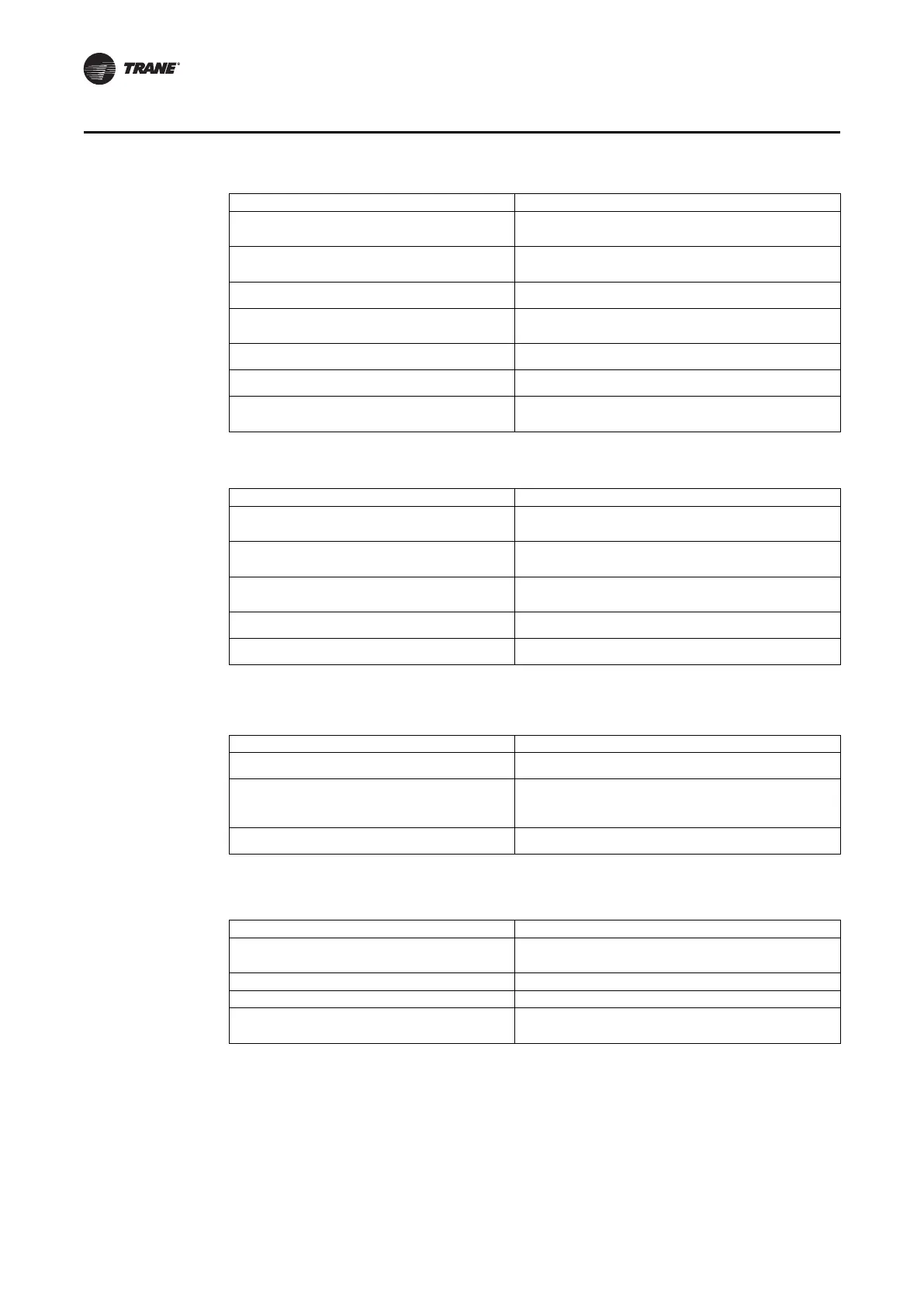

K. Too low discharge pressure

Possible cause Solution

Insufficient coolant (low superheat degree and

supercooling degree)

Supply coolant.

Blocked dry lter (temperature from coolant pipe to dryer

room is changed)

Change the dry lter

Improper regulation of expansion valve Regulate the expansion valve again.

Blocked expansion valve (too high superheat degree and

too high water temperature)

Repair or change the expansion valve.

Too low water ow of evaporator Check the lter screen and regulate water ow.

Non-condensed gas in the system Vacuumize the system and re-ll it with the coolant.

Leak of compressor valve and high suction pressure (high

high-pressure pressure, and low low-pressure pressure)

Change the compressor

Possible cause Solution

Insufcient charge of coolant (high superheat degree and

low supercooling degree)

Identify the leak point, repair it, and recharge the coolant.

Too low setting of temperature switch (too low low-

pressure pressure and too low outlet water temperature)

Regulate the temperature switch again.

Too low cold water ow

Check whether the filter screen is blocked and whether the

balance valve is correctly set.

Blocked dry lter Check whether the dry lter is frosted, and if necessary, change it.

Blocked expansion valve (high superheat degree) Clean or change the expansion valve.

Possible cause Solution

Inadequate coolant (high superheat degree, low

supercooling degree and air bubbles in the sight glass)

Identify the leak point, repair it, and recharge the coolant.

Rupture or leak of vent valve of compressor Change the compressor

Poor low voltage switch Change the poor control element.

Ensure minimum operating environmental temperature.

Exercise proper discharge pressure control or provide an ambient

temperature locking switch

Possible cause Solution

Too high cooling load (high supply water temperature) Please refer to Section E.

Excessive liquid feed of expansion valve (too low

superheat degree, leading to overowing of liquid onto the

compressor)

Regulate superheat setting and check whether the thermo probe

is mounted in the gas line.

Rupture of air suction valve (high noise of compressor) Change the compressor

Loading...

Loading...