30 RTAC-SVX002A-EN

Installation Mechanical

CAUTION

Proper Water Treatment!

The use of untreated or improperly

treated water in a unit may result in

scaling, erosion, corrosion, algae

or slime. It is recommended that

the services of a qualied water

treatment specialist be engaged to

determine what water treatment, if

any, is required. Trane assumes no

responsibility for equipment failures

which result from untreated or

improperly treated water, or saline or

brackish water.

If using an acidic commercial

ushing solution, construct a

temporary bypass around the

unit to prevent damage to internal

components of the evaporator.

Dirt, scale, products of corrosion and

other foreign material will adversely

affect heat transfer between the water

and system components. Foreign

matter in the chilled water system

can also increase pressure drop and,

consequently, reduce water ow. Proper

water treatment must be determined

locally, depending on the type of

system and local water characteristics.

el establecimiento de un programa

adecuado para el tratamiento del agua.

La utilización en estas unidades de

agua no tratada o tratada de manera

inadecuada puede provocar un

funcionamiento ineciente y posibles

daños a los tubos. Consultar a un

especialista calicado en tratamiento de

agua para determinar si es necesario

tal tratamiento. La siguiente etiqueta

de exención de responsabilidad está

presente en cada unidad RTAC:

Neither salt nor brackish water is

recommended for use in Trane air-

cooled Series R® chillers. Use of

either will lead to a shortened life to

an indeterminable degree. The Trane

Company encourages the employment

of a reputable water treatment special-

ist, familiar with local water conditions,

to assist in this determination and in

the establishment of a proper water

treatment program.

Using untreated or improperly treated

water in these units may result in

inefcient operation and possible tube

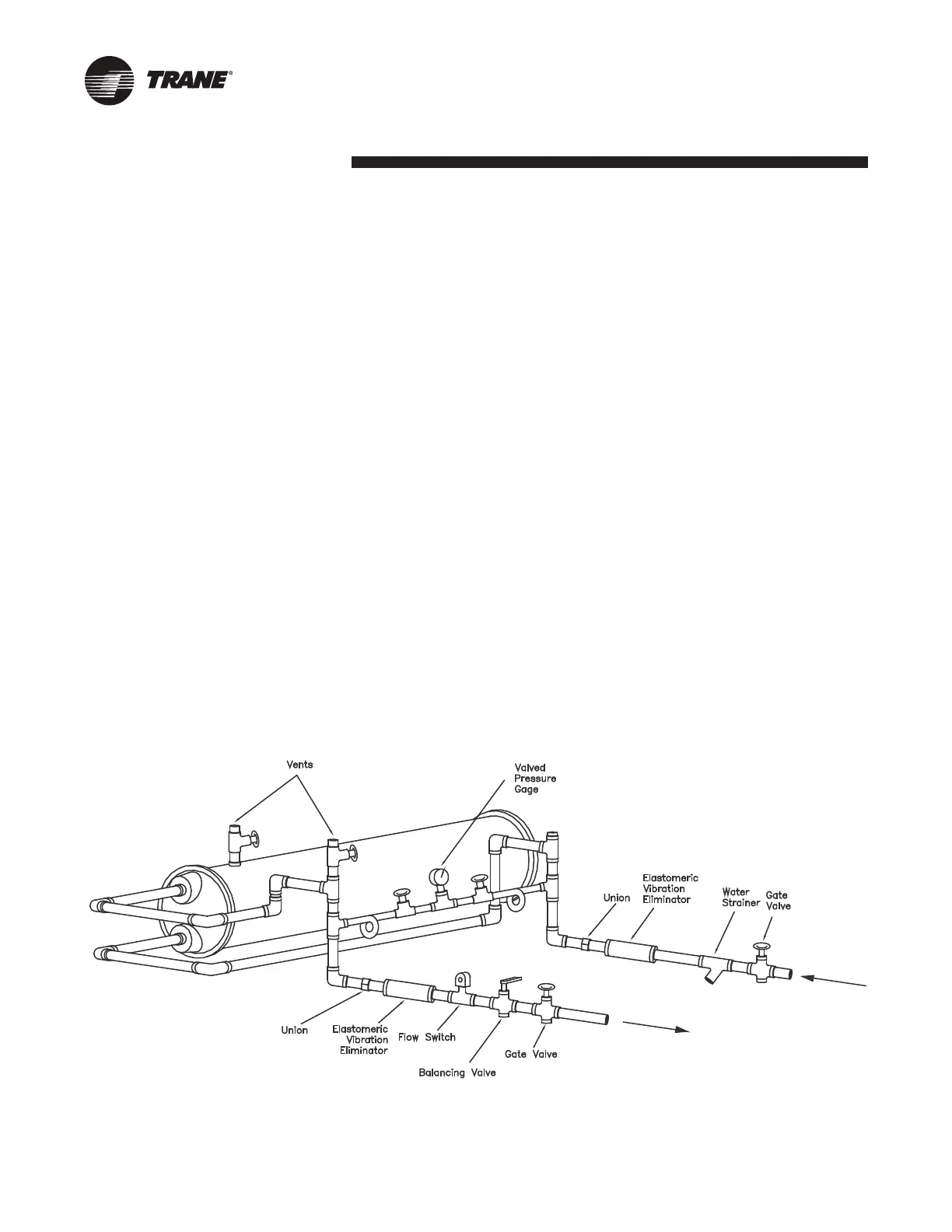

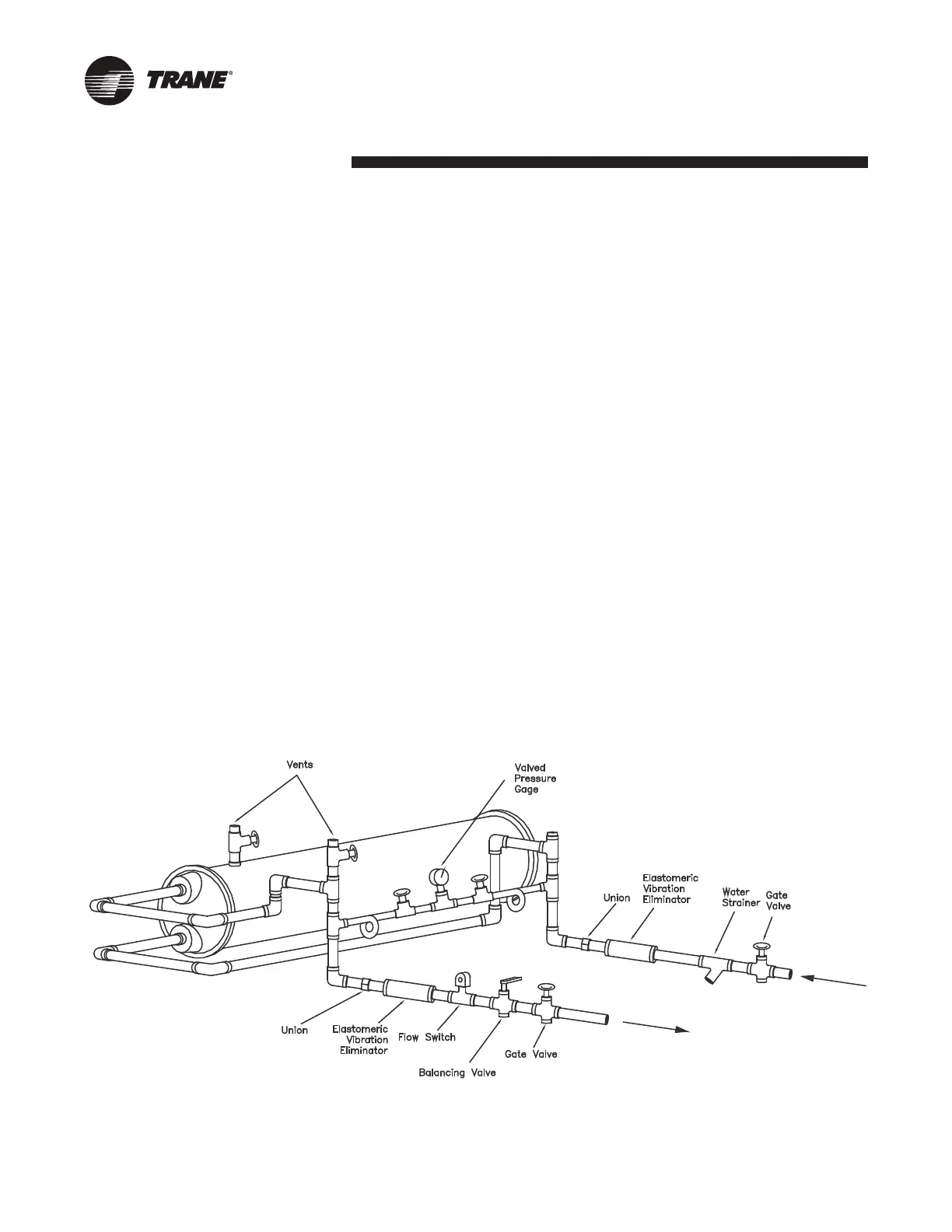

Fig. III-10 – Evaporator Water Pressure Drop

NOTE: Once the unit is installed at a site, one vertical or one diagonal unit support can be permanently removed if it creates an obstruction for water piping.

To read manifolded pressure gauges, open one valve and close the other (depending upon the reading desired). This eliminates errors resulting from differently

calibrated gauges installed at unmatched elevations.

damage. Consult a qualied water

treatment specialist to determine

whether treatment is needed. The

following disclamatory label is provided

on each RTAC unit:

NOTE: The use of improperly treated

or untreated water in this equipment

may result in scaling, erosion, corrosion,

algae or slime. The services of a

qualied water treatment specialist

should be engaged to determine what

treatment, if any, is advisable. The

Trane Company warranty specically

excludes liability for corrosion, erosion

or deterioration of Trane equipment.

Water Pressure Gauges

Install eld-supplied pressure

components as shown in Figure 25.

Locate pressure gauges or taps in a

straight run of pipe; avoid placement

near elbows, etc. Be sure to install

the gauges at the same elevation on

each shell if the shells have opposite

endwater connections.

Loading...

Loading...