User's Information

Regular Dealer Maintenance

ELECTRIC SHOCK HAZARD. To prevent injury or death due

to electrical shock or contact with moving parts. Lock unit

disconnect switch in open position before servicing unit.

Cooling Season

To keep your unit operating safely and efficiently, a qualified

service technician should check the entire system seasonally,

and any other time that you feel a check is needed. Your

service technician may examine these areas of the unit:

1. filters (for possible cleaning)

2. motors (condenser and evaporator motors are perma-

nently lubricated)

3. gaskets (for possible replacement)

4. refrigerant coils (for possible cleaning)

5. safety controls (for mechanical cleaning)

6. electrical components and wiring (for possible replace-

ment and connection tightness)

7. condensate drain (for possible cleaning)

8. inspect the unit duet connections to see that they are

physically sound and sealed to the unit casing.

9. inspect the unit mounting support to see that it is sound.

10.inspect the unit to see that there is no obvious unit

deterioration.

Heating Season

At the beginning of each heating season complete the unit

inspections and service routines described in this section.

These steps should be performed ONLY by a qualified service

technician.

1. Inspect the control panel wiring and heating controls to

make sure connections are tight and wiring insulation is

intact.

2. Cheek the operation of the gas ignition system.

a. Turn the unit on and off at the thermostat to be sure

the ignition control and spark electrode are operating.

b. Turn off the gas supply with the unit operating to

verify that the gas valve closes and that a re-ignition

cycle is initiated by the ignition control.

3. Check the burner manifold pressure. A pressure tap is

provided in the gas valve for this purpose.

4. Visually inspect all of the unit's flue product passageways

for excessive deposit buildup or corrosion. If buildup or

corrosion is apparent, perform the necessary repairs.

5. Arrange for a qualified service technician to inspect the

unit every heating season to maintain safe and efficient

operation.

6. Visually check the main burner flames. They should be

bright blue flames extending up to the heat exchanger

sections.

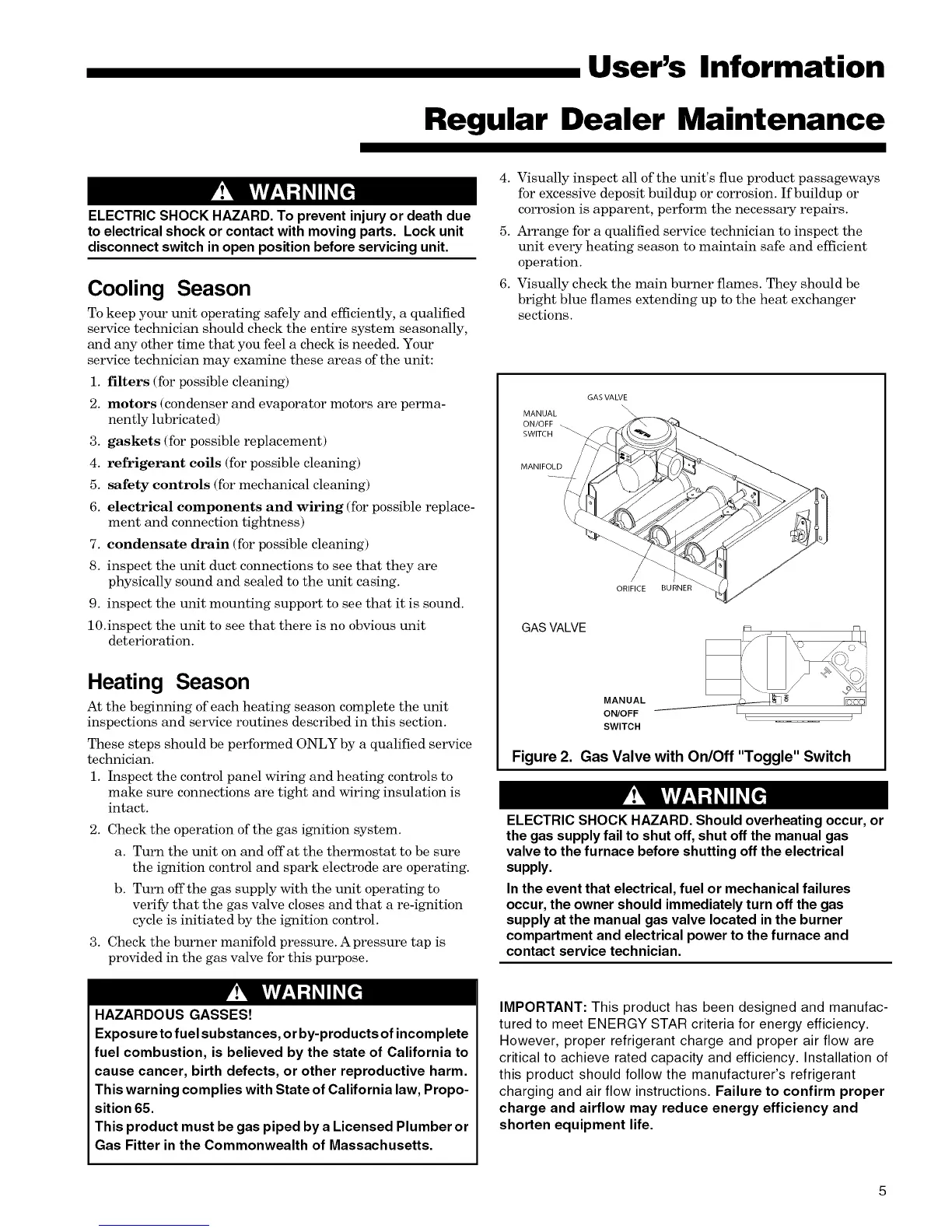

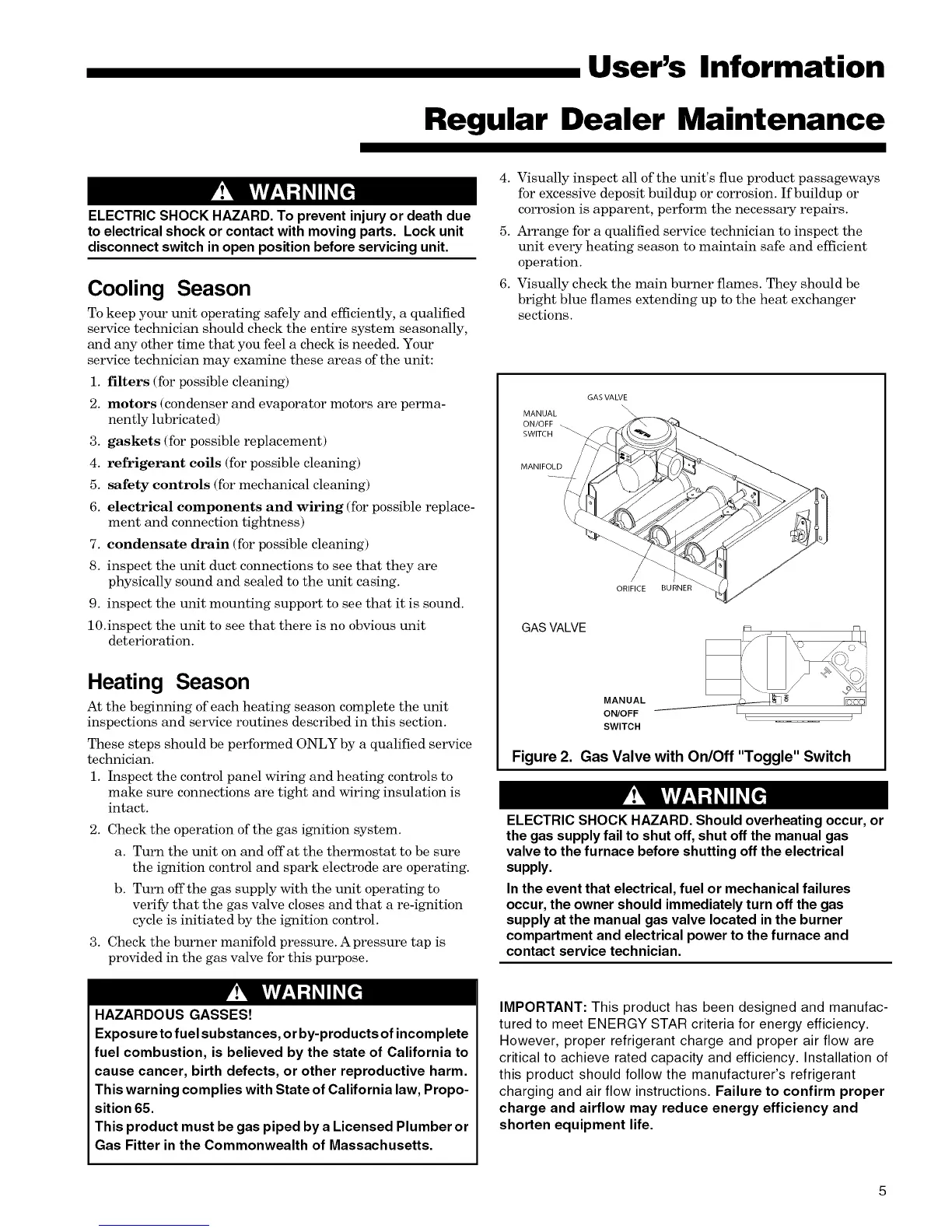

GAS VALVE

\\

MANUAL \\

ON/OFF __

SWITCH

MANIFOLD

ORIFICE BURNER

GAS VALVE

MANUAL

ON/OFF

SWITCH

R M

=k._/ ::

k

Figure 2. Gas Valve with On/Off "Toggle" Switch

ELECTRIC SHOCK HAZARD. Should overheating occur, or

the gas supply fail to shut off, shut off the manual gas

valve to the furnace before shutting off the electrical

supply.

In the event that electrical, fuel or mechanical failures

occur, the owner should immediately turn off the gas

supply at the manual gas valve located in the burner

compartment and electrical power to the furnace and

contact service technician.

V!'WkViVl-'!d

HAZARDOUS GASSES!

Exposure to fuel substances, or by-products of incomplete

fuel combustion, is believed by the state of California to

cause cancer, birth defects, or other reproductive harm.

This warning complies with State of California law, Propo-

sition 65.

This product must be gas piped by a Licensed Plumber or

Gas Fitter in the Commonwealth of Massachusetts.

IMPORTANT: This product has been designed and manufac-

tured to meet ENERGY STAR criteria for energy efficiency.

However, proper refrigerant charge and proper air flow are

critical to achieve rated capacity and efficiency. Installation of

this product should follow the manufacturer's refrigerant

charging and air flow instructions. Failure to confirm proper

charge and airflow may reduce energy efficiency and

shorten equipment life.

Loading...

Loading...