Sequence of Operation

RT-SVX21AC-EN 59

If the burner fails to ignite, the ignition module will attempt

two retries before locking out. The green LED will indicate

a lock out by two fast flashes. An ignition lockout can be

reset by;

1. Opening for 3 seconds and

closing the

main power

disconnect switch.

2. Switching the “Mode” switch on the zone sensor to

“OFF” an

d then to the d

esired position.

3. Allowing the ignition control module to reset

automaticall

y after one hour. Refer to the “Ignition

Control Module Diagnostics” section for the LED

diagnostic definitions.

When the fan selection switch is

set to the “Auto” position,

the RTRM

energizes the indoor fan relay (F) coil

approximately 30 second after initiating the heating cycle

to start the indoor fan motor (IDM).

Drain Pan Condensate Overflow Switch

(Optional)

This input incorporates the condensate overflow switch

(COF) mounted on the drain pan and the ReliaTel™

options module (RTOM). When the condensate level

reaches the trip point for 6 continuous seconds, the RTOM

will shut down all unit function until the overflow

condition has cleared. The unit will return to normal

operation after 6 continuous seconds with the COF in a

non-tripped condition. If the condensate level causes the

unit to shutdown more than 2 times in a 3 day period, the

unit will be locked-out of operation. A manual reset of the

diagnostic system through the zone sensor or Building

Automation System (BAS) will be required. Cycling unit

power will also clear the fault.

Electromechanical Controls

These units are offered with two control options,

electromechanical and ReliaTel™ controls. The ReliaTel™

controls is a microelectronic control feature, which

provides operating functions that are significantly

different than conventional electromechanical units.

Electromechanical Control Cooling

without an Economizer

When the thermostat switch is set to the “Cool” position

and the zone temperature rises above the cooling setpoint,

the thermostat Y contacts close. The compressor

contactor (CC1) coil is energized provided the low

pressure control (LPC1), high pressure control (HPC1) and

discharge line thermostat (TDL 1) are closed. When the

(CC1) contacts close, compressor (CPR1) and the outdoor

fan motor (ODM) start. If the first stage of cooling can not

satisfy the cooling requirement, the thermostat closes Y2.

The compressor contactor (CC2) coil is energized provided

the low pressure control (LPC2), high pressure control

(HPC2) and discharge line thermostat (TDL 2) are closed.

When the (CC2) contacts close, compressor (CPR2)

starts.

Electromechanical Control Evaporator Fan

Operation (for Gas Units)

When the thermostat fan selection switch is set to the

“Auto” position, the Ignition Module (IGN) energizes the

indoor fan relay (F) approximately 1 second after

energizing the compressor contactor coil (CC1) in the

cooling mode. In the heating mode, the Ignition Module

(IGN) energizes the indoor fan relay (F) coil approximately

45 second after gas ignition. Closing indoor fan relay (F)

coil starts the indoor fan motor (IDM). The (IGN) de-

energizes the fan relay (F) approximately 80 seconds after

the cooling requirement has been satisfied to enhance unit

efficiency.

When the heating cycle is terminated, the indoor fan relay

(F) coil

is de-en

ergized approximately 90 seconds after the

heating requirement.

When the thermostat fan selection switch is set to the

“On” position, the (IGN) keeps the in

door fan relay coil (F)

energized for continuous fan motor operation.

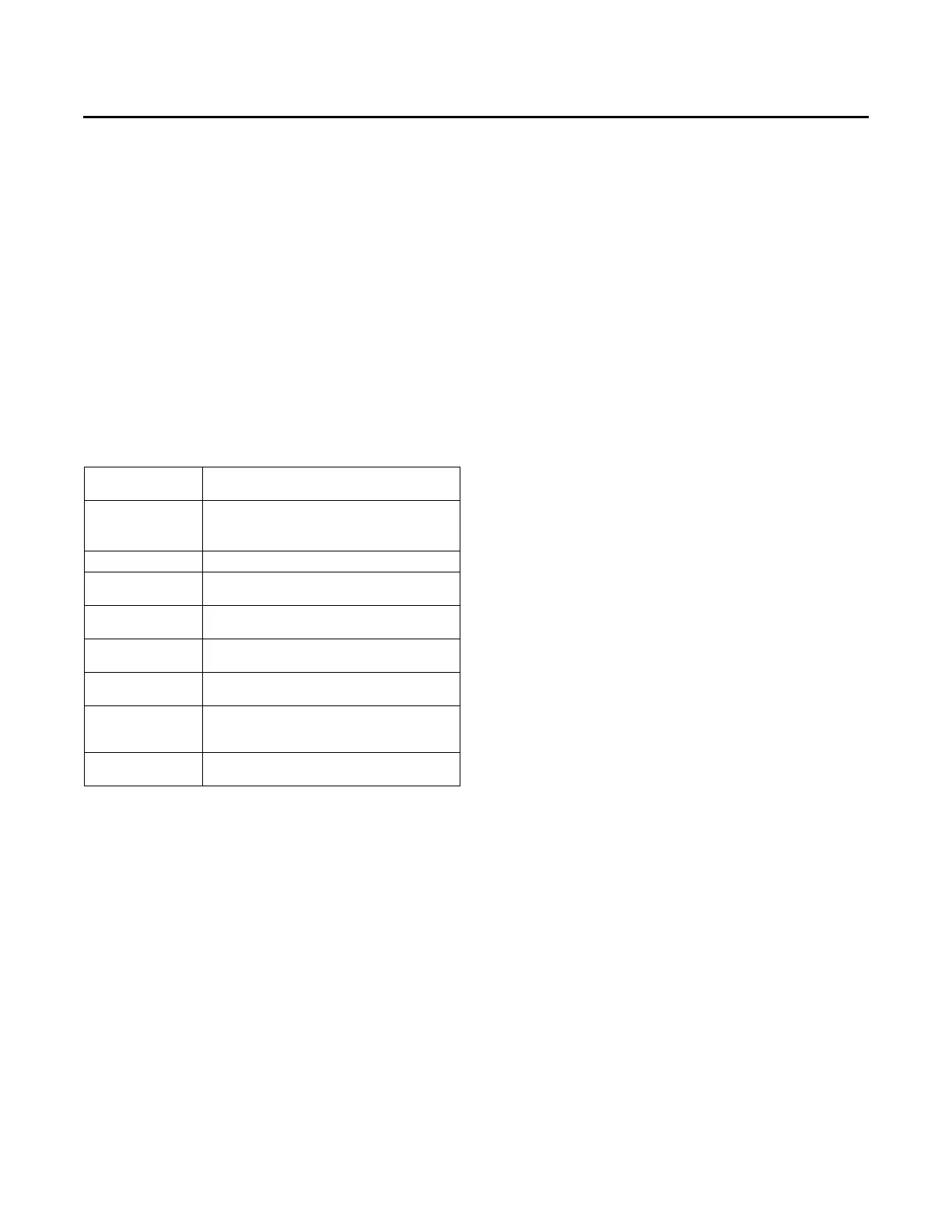

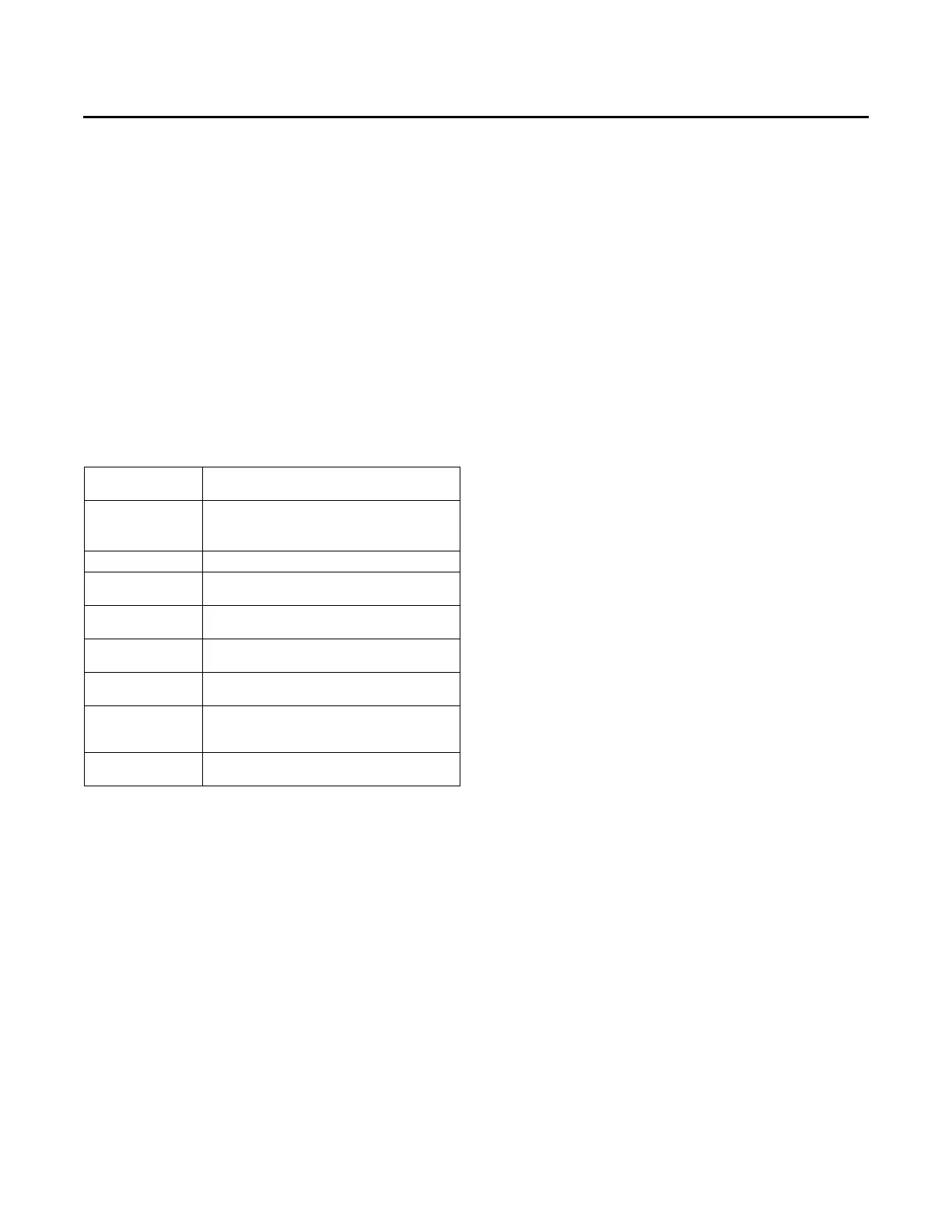

Table 19. Ignition module diagnostics

Steady light

Module is powered up, but no active call for

heat.

Blinking at

continuous

steady rate

Active call for heat.

One blink

Loss of communication.

Two blinks

System lockout (failure to ignite, no spark, low/

no gas pressure, etc.)

Three blinks

Pressure switch (no vent air flow, bad CBM,

closed at initial call for heat). Auto reset.

Four blinks

High limit (excessive heat in combustion

chamber, low airflow). Auto reset.

Five blinks

Flame sensed and gas valve not energized or

flame sensed and no call for heat.

Six blinks

Flame rollout (CBM failure, incorrect gas

pressure, incorrect primary air). Requires

manual reset of the switch.

Seven blinks

ReliaTel™ module will communicate a heat fail

diagnostic back to the RTRM.

Loading...

Loading...