SUMMIT

•

27

DUAL SERVO STEERING SYSTEM

Summit uses dual-servo steering and a single heavy-duty servo saver for

powerful, responsive steering. To prevent unnecessary receiver battery

drain, it is important to make sure that the servos are “at rest” when the

steering is at neutral. If one servo is out of adjustment, then both servos

will work against each other, fighting to find center.

Adjusting The Steering System

1.

Remove the servo horns and steering links from the servos.

Disconnect the steering links from the servo saver.

2.

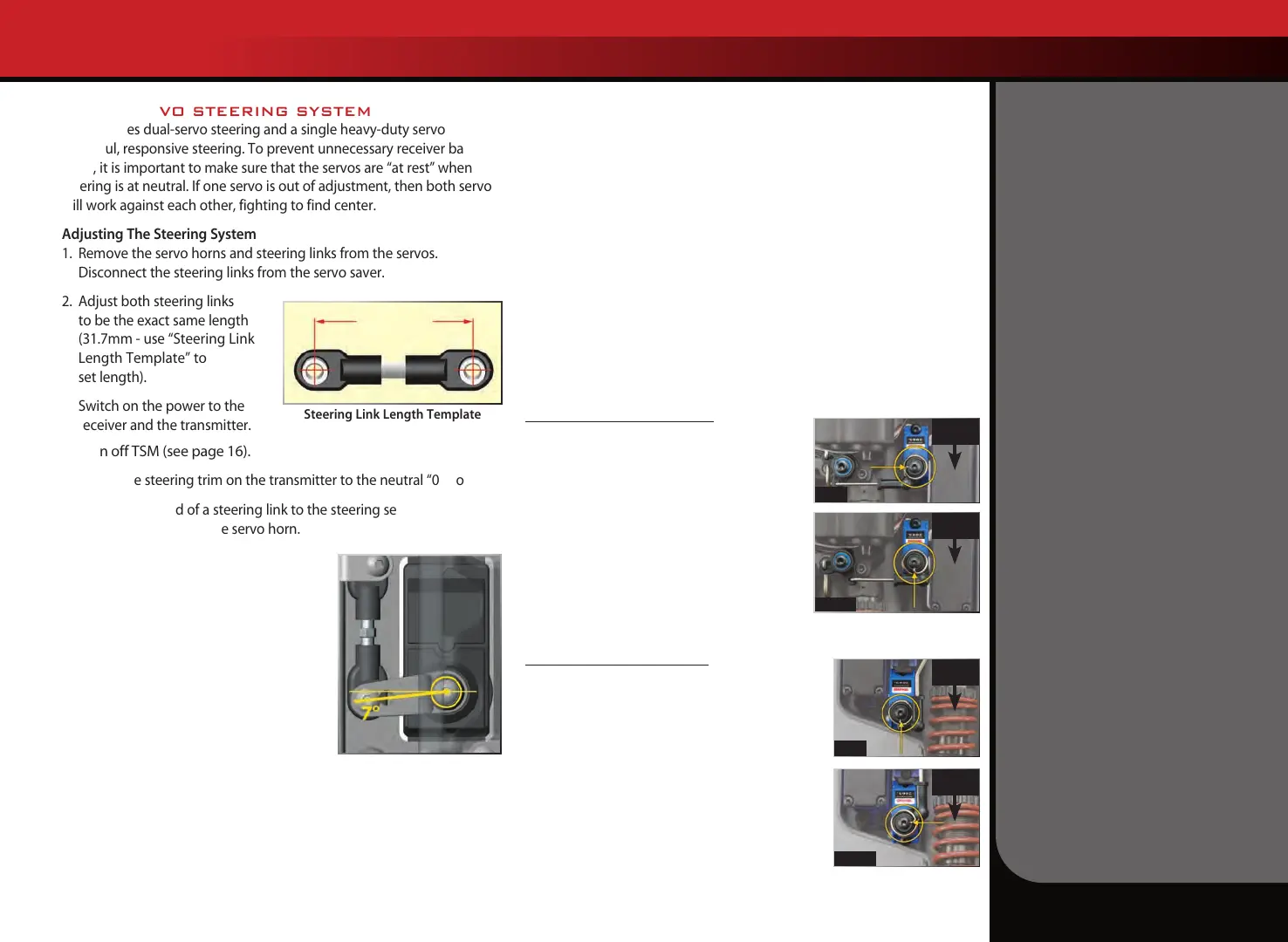

Adjust both steering links

to be the exact same length

(31.7mm - use “Steering Link

Length Template” to

set length).

3.

Switch on the power to the

receiver and the transmitter.

4. Turn off TSM (see page 16).

5. Adjust the steering trim on the transmitter to the neutral “0” position.

6. Connect one end of a steering link to the steering servo saver arm

and the other end to the servo horn.

7.

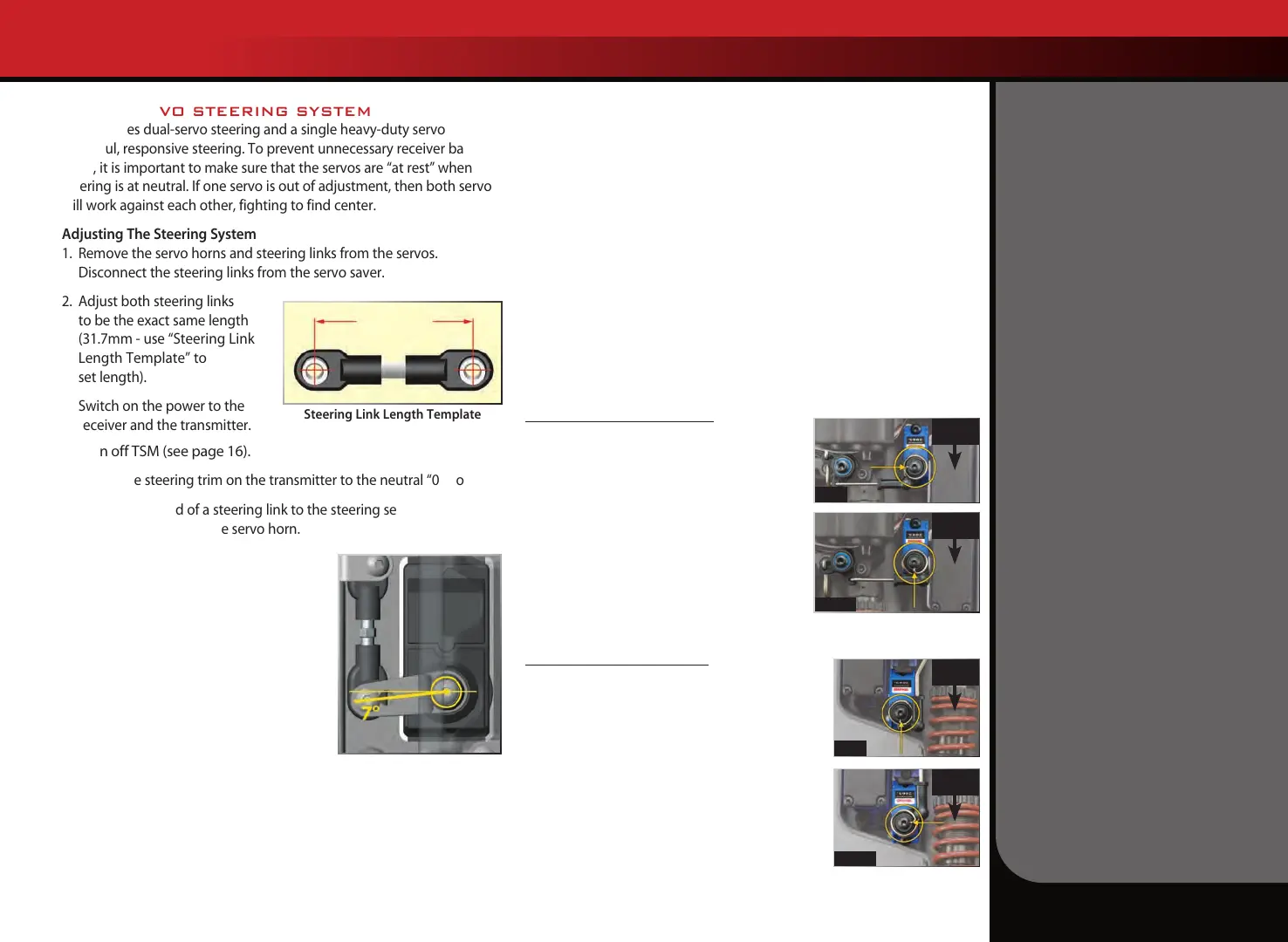

Position the steering servo saver arm

perpendicular to the centerline of the

vehicle.

8.

While holding the steering servo saver

arm in the position mentioned in step

6, install the servo horn onto the servo

such that the steering link is parallel

with the centerline of the vehicle. This

will automatically set the servo horn at

the 7-degree offset shown in

the illustration.

9.

Install the second servo horn on the other side following the same

procedure.

If necessary, fine-tune the length of the second steering link to

eliminate any load on the steering system in the neutral position. If you

are using aftermarket servos, it is important to use servo horns designed

for Summit. Optional steering servo horns are sold separately for use

with non-Traxxas servos.

T-LOCK SERVO INSTALLATION

The Summit’s T-Lock differential control servos are installed and pre-

set at the factory. If you need to remove the servos or the servo horns

for maintenance or cleaning, carefully note their orientation when you

reinstall them to make certain the T-Lock system operates properly.

Before reinstalling the spring-loaded servo horns, reset the servos’

output shafts to the “diffs open” position.

1. Switch the transmitter and receiver on and plug the T-Lock servos

into their correct positions on the receiver unit (see page 11).

2. Operate the transmitter’s T-Lock switch to make certain both servos

operate properly, then place the switch in the full-up position for

unlocked front and rear diffs (see page 19).

3. Install the servo horns as shown below. Switch the transmitter and

on-board electronics off before completing the installation.

Front Differential T-Lock Servo

Differential Open: Install the spring-loaded

servo horn so the spring slot is parallel to the

linkage and the bellcrank is pushed away from

the servo, as viewed in the photo.

Differential Locked: Switch the transmitter

and receiver on. Move the T-Lock switch to the

middle position to lock the front differential.

Confirm that the servo’s output shaft turns

counterclockwise to rotate the servo horn to the

position shown, with the spring slot perpendicular

to the linkage and the bellcrank pulled toward the servo.

Rear Differential T-Lock Servo

Differential Open: Install the spring-loaded servo

horn so the spring slot is parallel to the linkage

and the bellcrank is pulled toward the servo, as

viewed in the photo.

Differential Locked: Switch the transmitter and

receiver on. Move the T-Lock switch to the bottom

position to lock the rear differential. Confirm that

the servo’s output shaft turns counterclockwise to

rotate the servo horn to the position shown, with

the spring slot perpendicular to the linkage and

the bellcrank pushed away from the servo.

Steering Link Length Template

31.7mm

TUNING ADJUSTMENTS

Front of

Truck

Open

Open

Locked

Locked

Front of

Truck

Front of

Truck

Front of

Truck

Loading...

Loading...