Instructions for Use and Maintenance 120H-HY – 190H-HY (0901)

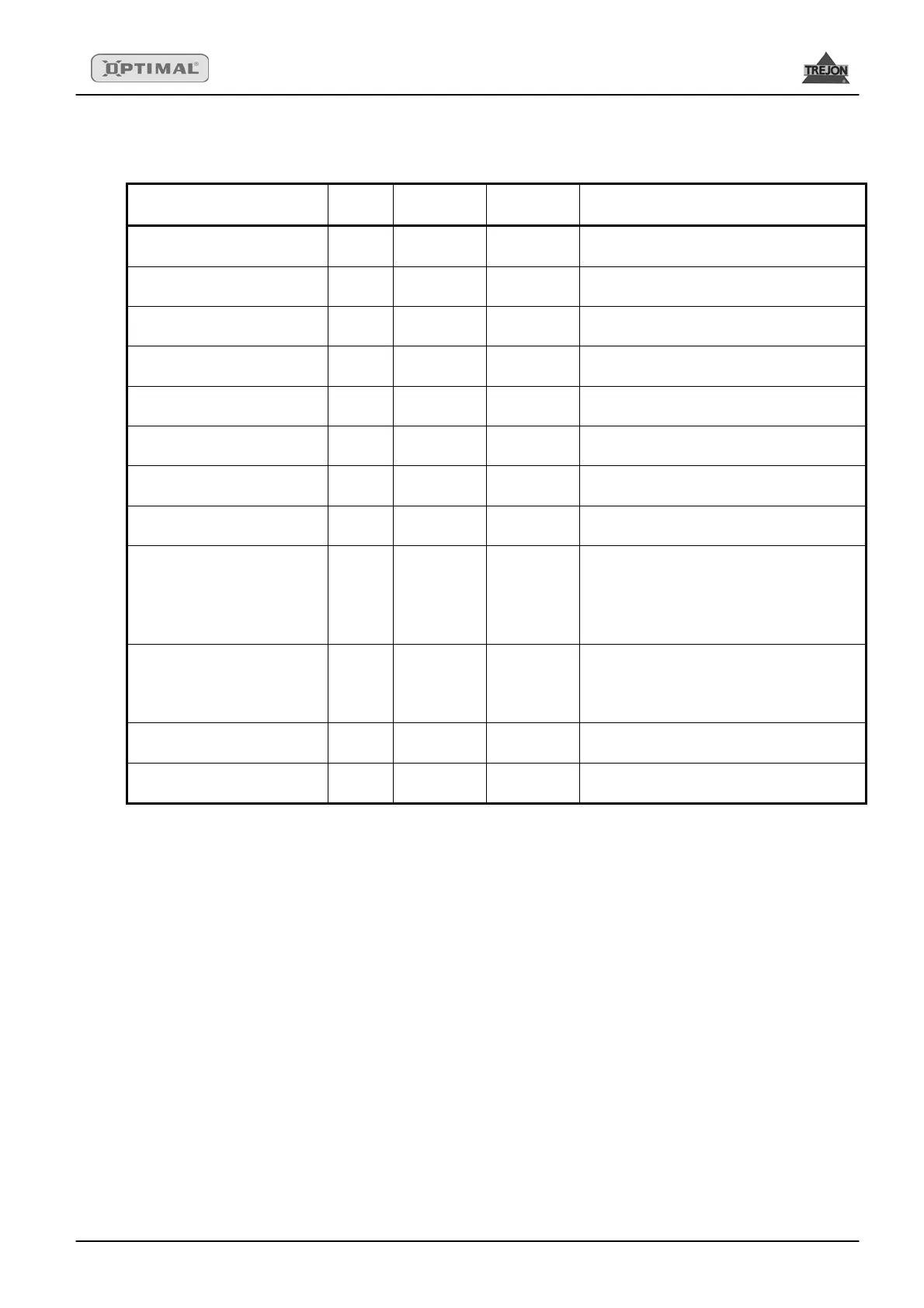

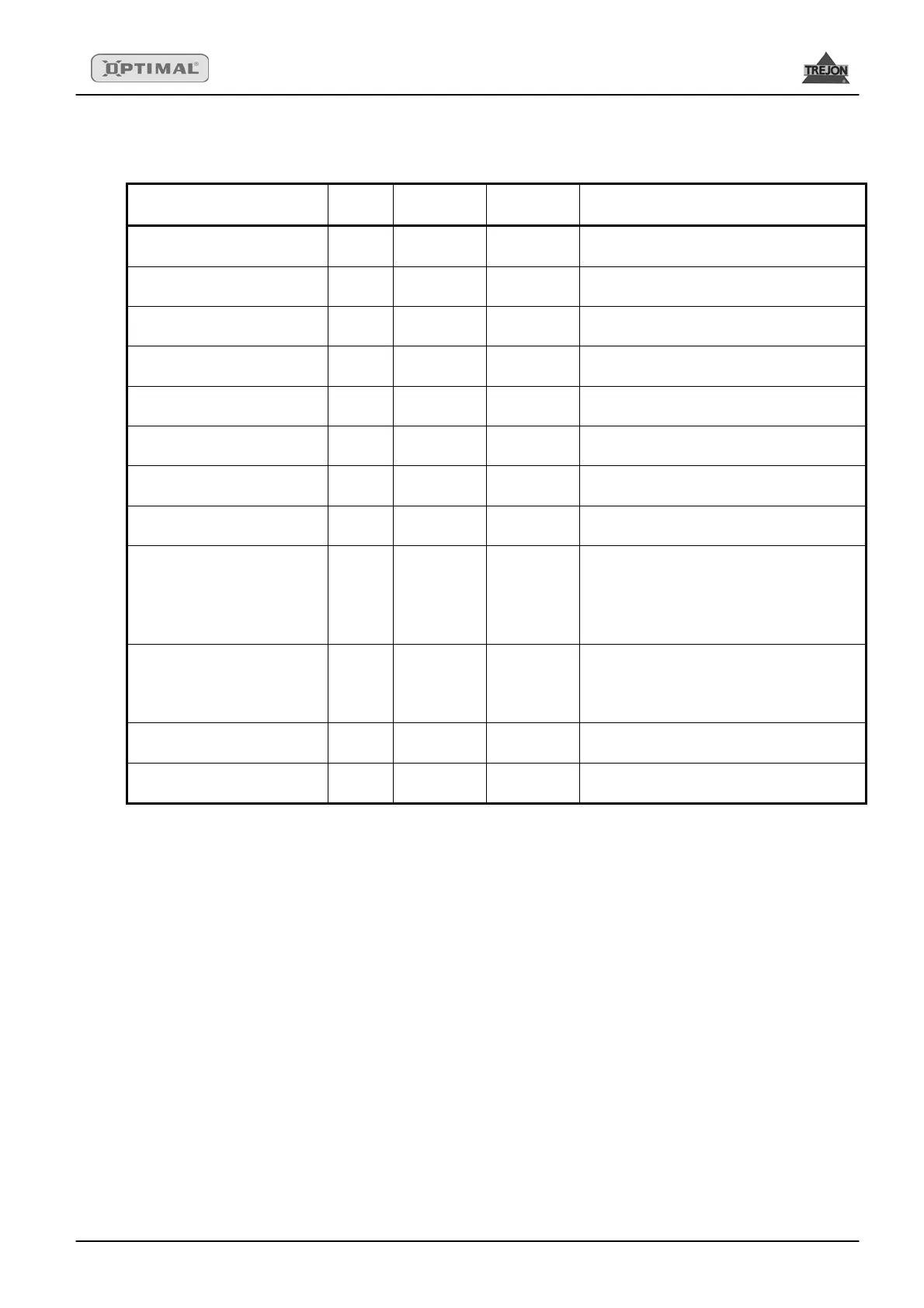

4.2 Maintenance schedule

Position Interv

al

Type Number Note

All screws and bolts 8 h Check

The whole

equipment

Check that all screws and bolts are

properly tightened and not loose.

Wearing edge Daily Check 1 pcs

Check the wearing edge for wear.

Turn over or replace as needed.

Cross shaft 40 h Grease 1 pcs NLGI2 EP

Shear bolt clutch

40 h

Grease 2 pcs NLGI2 EP

Feeding auger 40 h Grease

2pcs/

auger

NLGI2 EP

Transmission chain,

feeding auger

40 h Oil 1 pcs Engine oil 10W40

Transmission chain,

for gear box operation

40 h Oil 1 pcs Engine oil 10W40

Turntable gear 40 h Grease 2 pcs NLGI2 EP

Chain tensioner 40 h

Adjust-

ment

1 pcs

Check the tension. You should be

able to push the chain down about

7mm (9/32”) The feeder screw

should run smoothly without any

noise from the chain.

Gearbox 40 h Check 1 pcs

Visually check of the oil level, fill if

needed.

Oil SAE 80W/90 API GL4/GL5,

Industrial gear oil ISO VG 220

Gearbox

First

50 h

Oil change

Oil SAE 80W/90 API GL4/GL5,

ISO VG 220

Gearbox

500h/

yearly

Oil change

Oil SAE 80W/90 API GL4/GL5,

ISO VG 220

When lubricating use low temperature grease. These intervals are to be used for normal

usage. Always lubricate after cleaning with water.

trejonindustries.se

22

Loading...

Loading...