T5

-14-

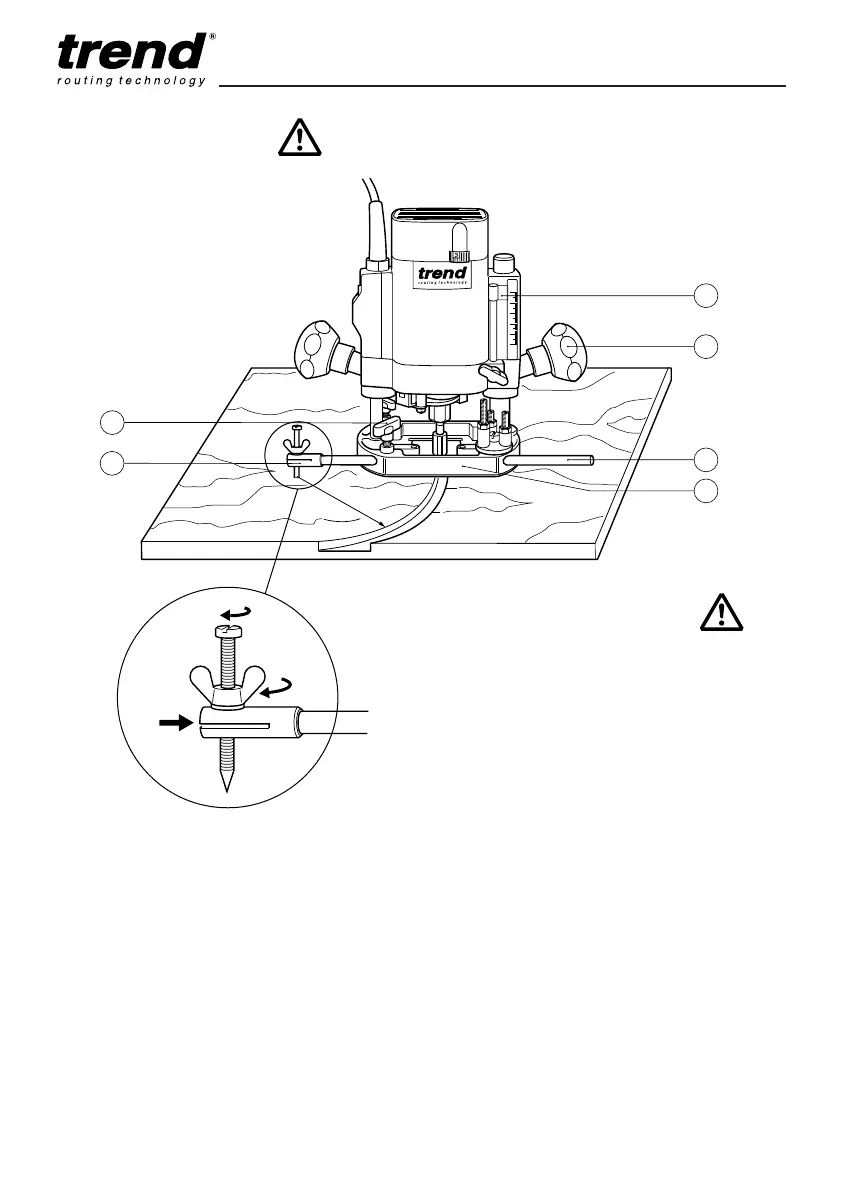

Beam Trammel Routing

Cutting Arcs with the Router

■ Place the machine on the workpiece.

■ Set the cutting depth using the depth stop (2).

■ Fasten the fence rod (1) in the routing base

(3) with the thumb knob (4).

■ Fit on the beam trammel point (5) as shown.

■ Measure the radius and fix the point of the

beam trammel in position.

■ Switch on the machine.

■ After releasing the plunge locking knob (6),

lower the machine slowly as far as the depth

stop and lock it there.

■ Cut grooves, rebates etc. at a steady rate of

feed, in an anti-clockwise direction. Ensure

the beam trammel point does not move.

■ When finished, release locking knob to raise

the machine.

■ Switch off the machine.

Fitting the beam trammel attachment

■ Fit the beam trammel attachment (A) to the

end of one rod and tighten wing nut (C)

securely.

■ Height adjustment of the pivot point can be

achieved by loosening wing nut (C) and

rotating screw (B).

■ Once set to the correct height, lock securely

wing nut (C).

MANU-T5 v8.0 1/9/05 12:06 pm Page 14

Loading...

Loading...