4

Select Description

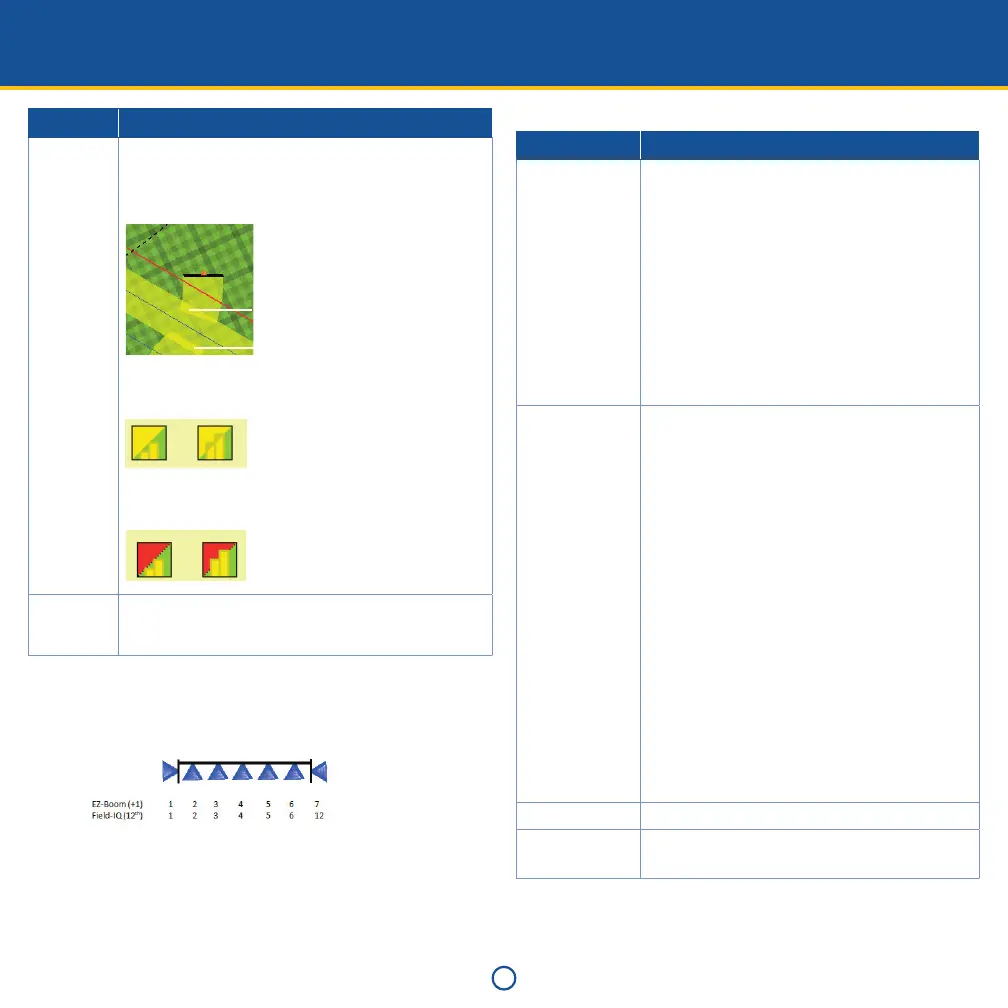

Overlap Start Overlap: The amount of intentional overlap when

going into a non-covered section of the field.

End Overlap: The amount of intentional overlap when

going into a previously covered area.

Start Overlap

End Overlap

Coverage Switching Overlap: The amount of side-to-side

coverage overlap before a section shuts down.

1%

99%

Boundary Switching Overlap: The amount of side-to-side

boundary overlap before a section shuts down.

1%

99%

Coverage

Allowable

Rate Error

Coverage allowable rate error.

c. If required, set Fence Nozzles. If Right or Both is selected, the

option for Right Nozzle Wiring appears. Select the wiring

configuration of your sprayer to ensure control of the correct

section for right fence nozzle:

7. Set up Rate Control.

a. If On, enter the number of drives for this location and select

the module serial number(s). If there is more than one module,

select the width associated with the module.

b. In Drive Setup, complete the Valve Setup. The options are:

Select Description

Valve Type • Servo: Standard 2-wire servo, performs more

slowly.

• Servo Fast: Fast 4-wire servo, performs more

quickly.

• PWM: 2-wire PWM valve, commonly used to

control hydraulic flow to the pump.

• Hardi % Bypass Servo: Used on Hardi sprayers

equipped with 3-way section valves that return

flow to the tank when the boom section is off.

• Pump Servo: Servo valve commonly used to

control hydraulic flow to the pump.

• Electric Over Hydraulic: A valve that uses electric

current to control the hydraulic valve output.

Plumbing Set the valve plumbing for servo-type valves only

(that is, Servo, Servo Fast, and Hardi % Bypass

Servo).

Note – Pump Servo does not have a plumbing type as it

controls hydraulic flow to the pump. This is similar to a

PWM setup.

The options are:

• Inline: The control valve is between the pump

and the sections/nozzles. This means that the

control valve controls the amount of material

out to the section/nozzles directly.

Note – To increase the amount of material that is sent

to the section/nozzles, the control valve must open

more in order to force more material to the sections/

nozzles.

• Bypass: The control valve is between the pump

and the tank. This means that the control valve

controls the amount of material that goes back

to the tank.

Note – To increase the amount of material that is sent

to the section/nozzles, the control valve must close

more in order to force more material to the sections/

nozzles.

Auxiliary Valve Disabled, Master, or Dump

Pump Disarming

Switch

Disabled or Enabled

Loading...

Loading...