9

Dust extraction port

Note: The Triton Router is equipped with a Dust Extraction Port (15) for chip extraction above

the cut. The Dust Extraction Port accepts 38mm (1½") O.D. hose, supplied with the Triton Dust

Collector (DCA300).

• The dust extraction hose screws into position via a left hand thread

(anti-clockwise) (Image D)

Optional chip collector accessory

• An optional Dust Chute for effective chip extraction alongside the cut zone is available

through your local Triton retailer. It can be connected to any 38mm (1-½") O.D. hose

(Image E)

Extended baseplate & fence installation

1. Locate the two Baseplate Mounting Knobs (13) and loosen them completely. This permits

the mounting studs to engage the router securing holes on the Extended Baseplate (27)

2. Turn both the plunge router and the Extended Baseplate upside down

3. Press the Baseplate Mounting Knobs on the plunge router inwards, to expose the

mounting studs

4. Align the mounting studs with the router securing holes on the Extended Baseplate, and

slide into the keyhole slots (Image K)

Note: The orientation of the Extended Baseplate depends on where the support is required.

For edge work, locate the On/Off Power Switch (8) on the short overhang side of the base

5. Tighten the Baseplate Mounting Knobs on the plunge router firmly to secure the plunge

router to the Extended Baseplate

6. To fit the Fence (22) loosen the fence knobs, and slide the Fence along the tracks on the

Extended Baseplate (Image L). Lock at the required setting by tightening both fence knobs

Note:When routing trenches at distance from an edge, fit the Fence to the long end of the

Extended Baseplate.

Note: When performing edge work with a non-bearing guided cutter, fit the Fence to the short

end of the baseplate (Image J).

Note: If using a very large diameter cutter it may be necessary to fix wooden blocks to the

fence faces via the screw holes, to ensure the cutter does not contact the Fence.

Operation

WARNING: ALWAYS wear eye protection, adequate respiratory and hearing

protection, as well as suitable gloves, when working with this tool.

Switching ON & OFF

Note: When the router is connected to the power source, the On/Off

Power Switch (8) will illuminate in both ‘On’ and ‘Off’ positions.

Note: The Retracting Power Switch Cover (7) prevents accidental starting of the

router. It must be retracted before the router can be switched on. The Retracting

Power Switch Cover will remain open until the router is switched off.

1. Ensure that the plunge router is at the maximum extension of its travel, and that

the cutter will not conflict with any foreign objects when it is powered on

2. Connect the power cord to the mains, and slide the Retracting Power

Switch Cover back to reveal the On/Off Power Switch

3. Press the On/Off Power Switch in the ‘I’ position to turn the plunge router ON.

Whilst the On/Off Power Switch is in this position, the Retracting Power Switch

Cover will be prevented from re-covering the On/Off Power Switch

4. To turn OFF, press the On/Off Power Switch in the ‘O’ position. The

Retracting Power Switch Cover will slide back to its original position

Variable speed control

Note: Router speed settings are not critical. Generally the highest speed that

does not cause burn marks on the workpiece should be used. Where stated,

always follow the cutter manufacturers’ maximum speed limitations.

• Operating at reduced speed increases the risk of damage to the router as a

result of overload. Use very slow feed rates and/or multiple shallow cuts

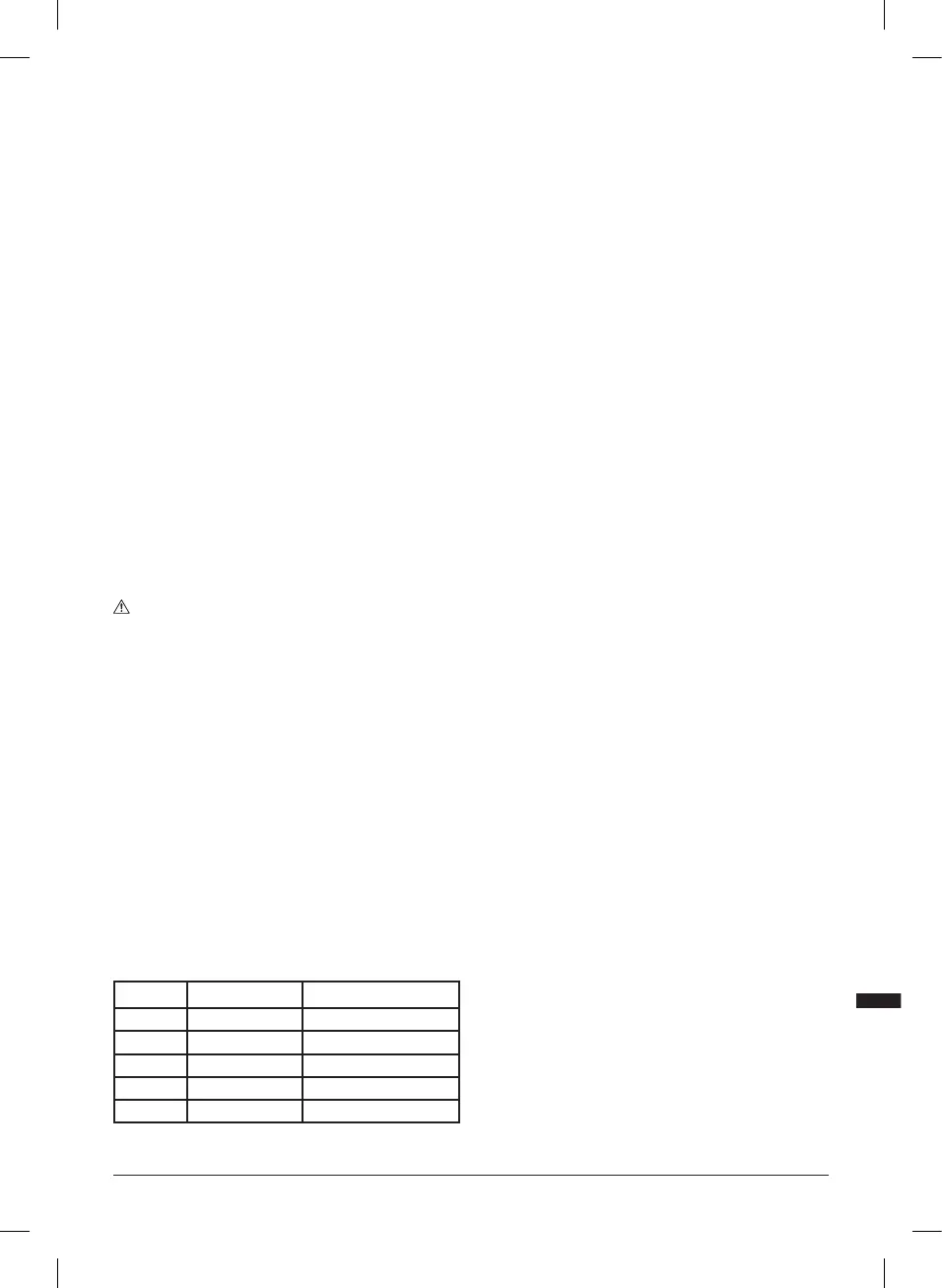

• The Speed Controller (10) is marked 1 to 5, corresponding approximately with the

speeds and cutter diameters below. Turn the dial to select the required speed

Setting RPM Cutter Diameter

5 21,000

Up to 25mm (1")

4 18,000

25-50mm (1"- 2")

3 14,500

50-65mm (2"- 2

1

⁄2")

2 11,000

Over 65mm (2

1

⁄2")

1 8000 Use only if burning

Cutting depth adjustment

Note: To lock the router at a particular depth of cut, plunge the router head down and rotate

the Plunge Lock Lever (11) to its lower position. This will hold the router head in this position.

• There are three methods of cut depth adjustment, depending on the accuracy and

control required:

Free plunge

1. Free plunge depth adjustments can be made with the Plunge Selection Button (18)

engaged. Press the Plunge Selection Button deep inside the handle until it engages inward

(Image A)

2. Release the Plunge Lock Lever (11) and push the body of the router until the required

depth is reached. Re-lock the Plunge Lock Lever

Winder handle adjustment

1. Plunge depth adjustments can be made by turning the Winder Handle (19)

2. Disengage the Plunge Selection Button (18), and ensure the button is flush with the

Winder Handle (Image K)

3. To release the Winder Handle, pull the Winder Handle Clutch Ring (17) inwards (Image B)

4. Release the Plunge Lock Lever (11) and twist the Winder Handle until the desired depth of

cut is reached. Release the Winder Handle Clutch Ring, and lock the Plunge Lock Lever

Micro Winder

Note: For use in Winder Handle (19) plunge mode only.

1. Disengage the Plunge Selection Button (18), and ensure that the Plunge Lock Lever (11) is

unlocked

Note: If the Micro Winder (20) is turned with the Plunge Lock Lever engaged, the Micro Winder

will start clicking and the cut depth will remain unchanged.

2. Turn the Micro Winder clockwise to increase cut depth and anti-clockwise to reduce cut

depth. Adjust the cut depth until the desired height is reached

Note: When the end of the depth adjustment range is reached, the Micro Winder will offer

greater resistance and will begin to ‘click’.

3. Engage the Plunge Lock Lever, particularly for heavy cuts

Depth stop & turret

1. The Depth Stop (3) and Turret Stops (1) are used to accurately pre-set up to three different

cut depths

2. Loosen the Depth Stop Lock Knob (5) and retract the Depth Stop (3) fully, then re-tighten

(Image F)

3. Set the turret posts to the required plunge depths using the scales on the stationary turret

post (Image G)

Note: To change turret posts, rotate the entire turret assembly to align with the Depth Stop.

4. With the desired cutter installed into the Collet (23), adjust the plunge depth until the tip of

the cutter touches the workpiece

5. Rotate the turret until the fixed turret post is in line with the Depth Stop. Release the stop,

allowing it to spring on to the post, then re-tighten the Depth Stop Lock Knob. The plunge

depth is now set at zero

6. Rotate the Turret Stops until the turret post with the desired plunge depth is aligned with

the Depth Stop

Optional template guide bushes

Different template guide bushes are available for template routing. Accessory kits are available

through your local Triton retailer.

Making a cut

Note: NEVER operate the router freehand without some form of guide. Guidance can be

provided by a bearing guided router bit cutter, the supplied guides, or a straight edge (Image I).

1. ALWAYS hold the router using both hands, on the handles provided. Ensure that the

workpiece will not move. Use clamps wherever possible

2. Allow the motor to reach its full operating speed

3. Lower the router bit cutter into the workpiece whilst moving the router slowly, keeping the

baseplate held flat against the workpiece

4. If edge cutting, the cutting of the workpiece should be on the left side relative to the

cutting direction, (Fig I). Keep the pressure constant and allow the cutter to work

steadily through the material. Be aware that knots, and other variations, will slow

the rate of progress

Note: To avoid ‘bit chatter’, direct the cut anti-clockwise for external cuts, and clockwise for

internal cuts.

Note: Moving the router too fast can result in a poor quality finish, and overloading of the

motor. Moving the router too slowly can result in overheating the workpiece.

Note: Normal operation of a router is to plunge the head after the router has been switched on.

Note: Do not operate the router upside down unless securely mounted in a well-guarded router

table (e.g. Triton brand).

330165_OwnerManual_08JUL21 .indd 9330165_OwnerManual_08JUL21 .indd 9 09/07/2021 09:1609/07/2021 09:16

Loading...

Loading...