45

CABLE INSPECTION AND MAINTENANCE

One of the most critical areas that require frequent inspection on any weight machine is the cable or belt system that

lifts the weight stack if the machine is equipped with those items. Sudden failure of a worn cable can, in some instances,

result in injury to the user. It is the responsibility of the facility to inspect the cables frequently. Cables are components that

wear over time. This means that the more often a piece of equipment is used, the greater the likelihood that cable wear

will occur. This holds true for equipment made by any manufacturer and applies to urethane belts as well as wire rope

cables. Listed below are the areas of the cable that require inspection.

IMPORTANT! TRUE recommends that all cables be replaced on an annual basis to maintain the safety of all users.

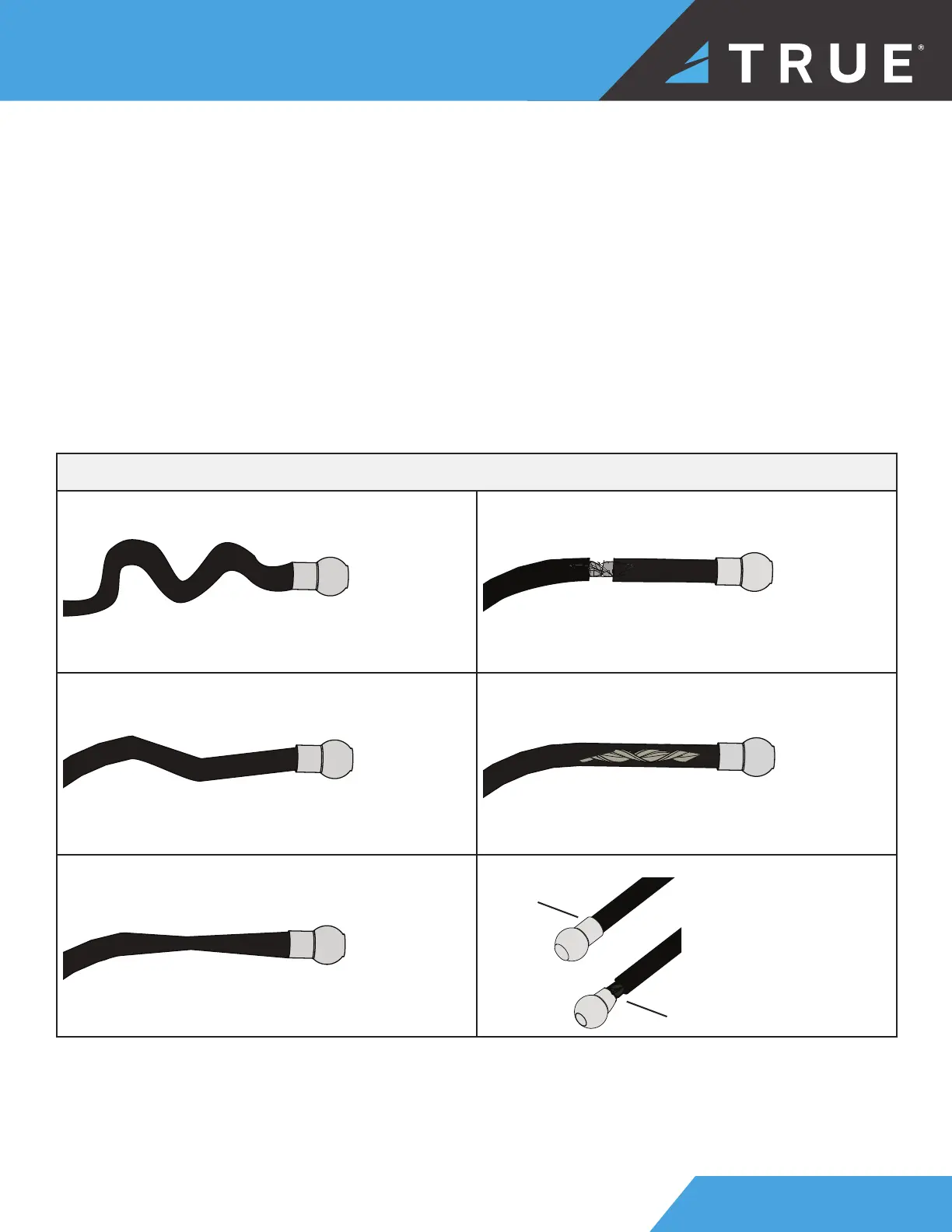

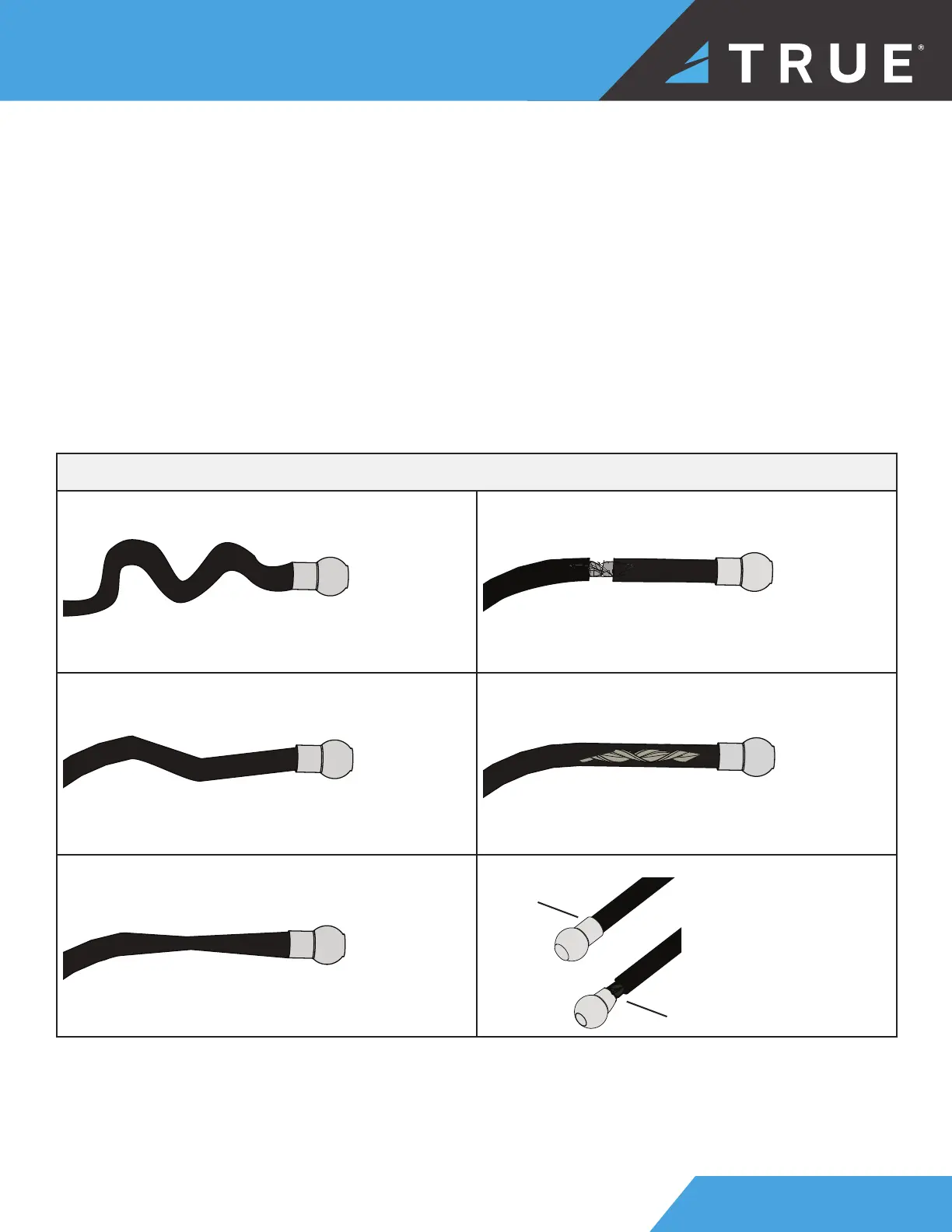

CABLE WEAR

Inspect all cables for any signs of wear. Pay close attention to the cable in the area of the end fi ttings and attachment

points. Inspect the areas around the pulleys and/or cams. Shown below are examples of cables that exhibit signs of

potential failure. If any of these conditions are apparent, the machine should immediately be taken out of service and

repaired. Be sure to use only cables supplied by TRUE. DO NOT use cables that have fi ttings attached with hand-crimp

tools.

Examples of Cable Wear

Twisted Cable (Zig-Zag Pattern) Break in the Cable Cover

Break or Bend in the Cable Tear in the Cable Cover

Stretched Cable Covering Crimp Connector Dislodged

Bad

Good

Loading...

Loading...