46

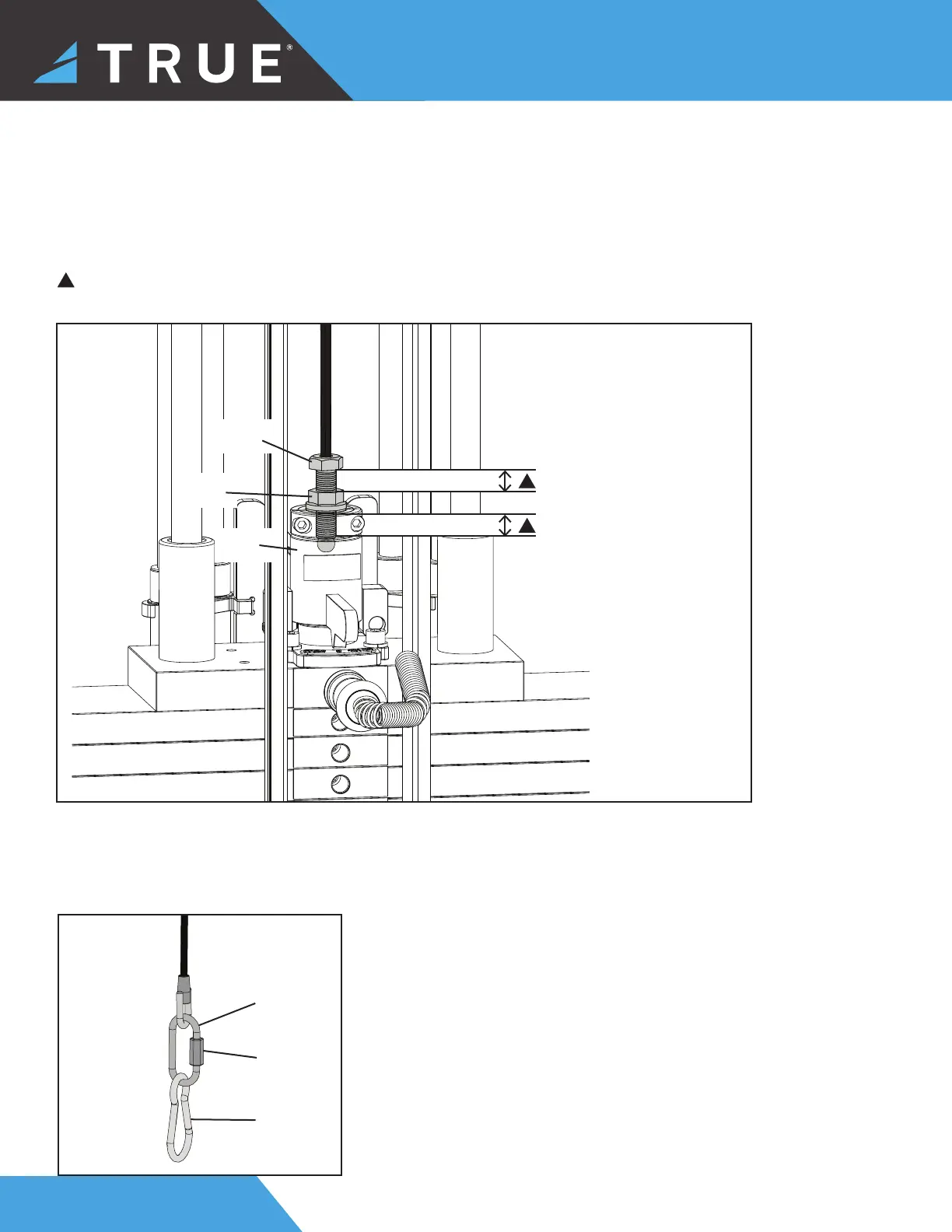

HANDLE FITTINGS (IF APPLICABLE)

Inspect the cable and fi ttings where handles are attached to the end of the cable. The fi ttings originally supplied with your

machine are load rated snap-links and quick-links. Be sure the hex nut on the quick link is fully tightened. Be sure that the

snap-link opens and closes easily and is fully engaged when closed. Replace if either are damaged.

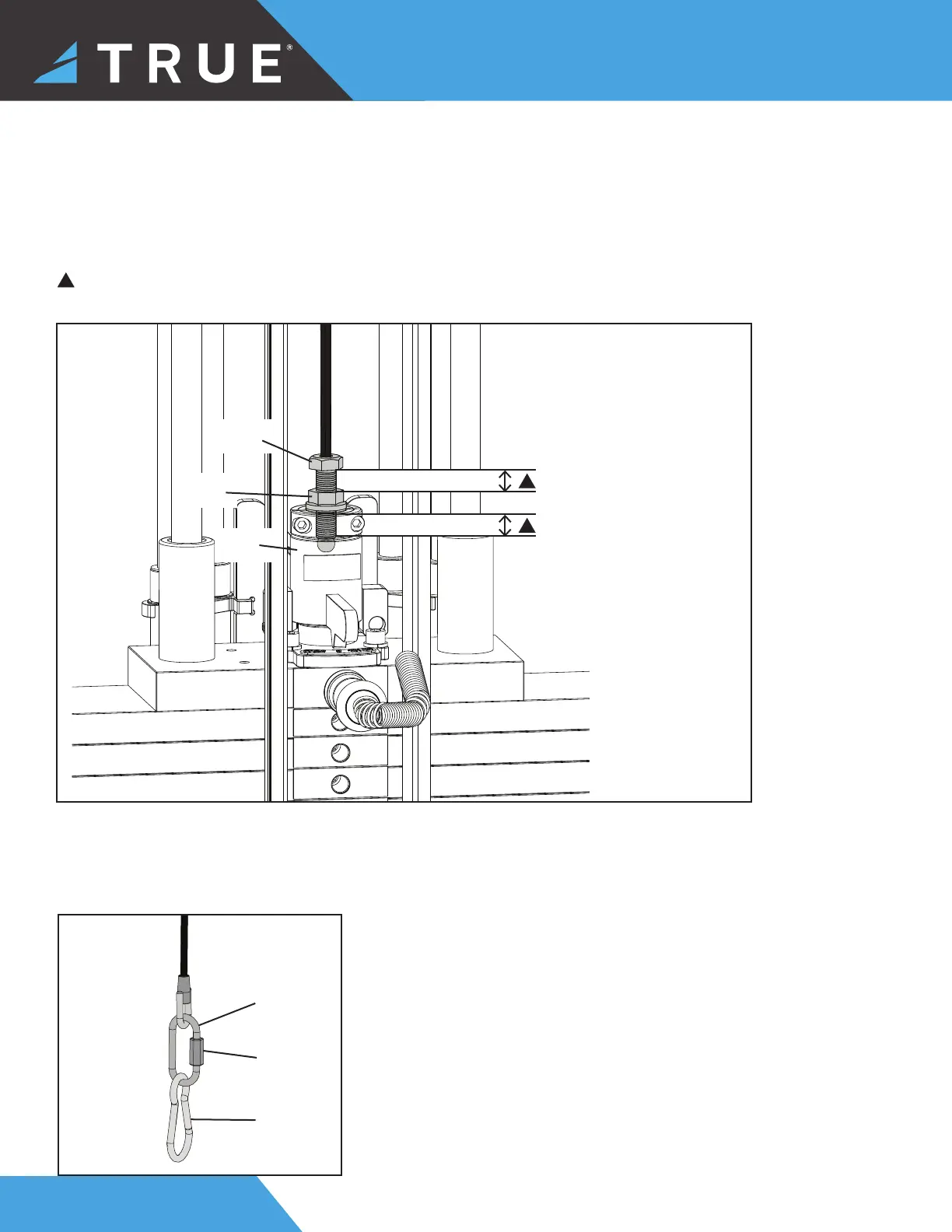

CABLE TENSION

Ensure that the cables are adjusted to remove any slack using the threaded end fi ttings. These are normally located at

the weight stack connection. Depending upon the machine, there may be multiple threaded fi tting on multiple cables. You

can determine if there is too much slack by performing the exercise. As you start to move a load arm or handle, the weight

stack should lift immediately. If not, the cable tension needs to be adjusted.

To adjust the cable tension, loosen the cable nut that is located on the cable bolt connected to the top plate. Tighten the

cable bolt until the top plate is barely lifted off of the fi rst weight plate and then re-tighten the cable nut.

!

CAUTION: A minimum of ¹⁄" (12.7mm) of the threaded portion of the cable bolt must be threaded into the top plate. No

more than 1" (25.4 mm) of the threaded portion of the cable bolt should be visible.

Top

Plate

Cable

Bolt

Cable

Nut

¹⁄๙" (12.7mm) minimum

1" (25.4mm) maximum

!

!

Hex

Nut

Quick

Link

Snap

Link

Loading...

Loading...