9

Connecting the

room temperature

sensor and control

panel to the system

Fig. N: Take off the top cover

of the electronic control unit

(54) and plug in the connec-

tion cable from the room

temperature sensor (55 – no

need to be concerned about

polarity), the control panel

(48), and, if appropriate, the

timer switch (56). Slide the

cover back on.

Electrical

connection 12 V

Electric cables, switching

units and control units for

heaters must be arranged in

the vehicle in such a way that

their satisfactory operation

cannot be adversely affected

under normal operating con-

ditions. All cables leading to

the outside must be splash

proof at the leadthrough

opening.

Prior to working on electric

components the appliance

must be disconnected from

the power supply. Switching

off at the control panel is not

sufficient!

When carrying out electric

welding work on the body

the appliance connection

must be disconnected from

the vehicle electrical system.

If the connections are

transposed there is a

risk of cable burning. This al-

so rules out any guarantee or

liability claims.

Fig. N: To guarantee optimum

power supply, the heating

system must be connected

to the fused on-board net-

work (central electronics unit

10 A) with a 2 x 2.5 mm

2

cable (for lengths over 6 m

with 2 x 4 mm

2

cable). If rele-

vant, voltage drops in the

supply cable must be taken

into account. Connect the

negative lead to the central

earth. If connected directly to

the battery, the positive and

negative leads must be

fused. Use fully-insulated

6.3 mm push-on receptacles

(57) for the connection.

Do not connect any other

consumers to the supply line!

When using power packs,

please observe that the

appliance is only to be oper-

ated with safety extra-low

voltage in accordance with

EN 60742!

The Truma battery

charger NT 12/ 3-18

(Art. no. 39901-01) is recom-

mended for connecting multi-

ple 12 V devices. This charger

(with a charging current of

18 A) is suitable for charging

lead-acid or lead-gel batter-

ies. Other chargers must only

be used with a 12 V battery

as a buffer. Mains power sup-

plies and other power supply

equipment must have a con-

trolled 12 V output (AC com-

ponent less than 1 V).

For saving the battery

we recommend using

solar collectors. Please ask

for information from your

dealer.

Electrical connection

of the safety/drain

valve

Fig. G: Connect the valve

with the red continuous cur-

rent cable (+) to the fused

vehicle power supply (1 A).

Connect the 2-pin cable with

double connector (58) to the

control panel. Truma supplies

a 50 cm long extension cable

(Art no. 70070-08500) as a

special accessory.

It must be ensured that the

cable is not routed over the

air distribution pipes and/or

any hot parts of the equip-

ment such as the base!

The brown cable (59) is pro-

vided for the remote control

of the safety/drain valve (refer

to operating instructions –

accessories).

Electrical

connection 230 V

(special version)

The electrical connec-

tion is only to be

carried out by an expert (in

Germany, acc. to VDE 0100,

Section 721). The information

given here is not intended as

instructions for you to carry

out. It is for assisting the ex-

pert assigned to carry out the

job, acting as auxiliary infor-

mation when connecting the

appliance!

Connection to the mains sup-

ply is effected by means of

cables 3 x 1.5 mm

2

(e.g. hose

line H05VV-F) to a distributor

box (not included in the

scope of supply).

Always make sure to connect

carefully, observing the cor-

rect colours!

For maintenance and repair

work a disconnecting device

must be provided on the ve-

hicle for all-pole disconnec-

tion from the power supply,

with at least 3.5 mm contact

clearance.

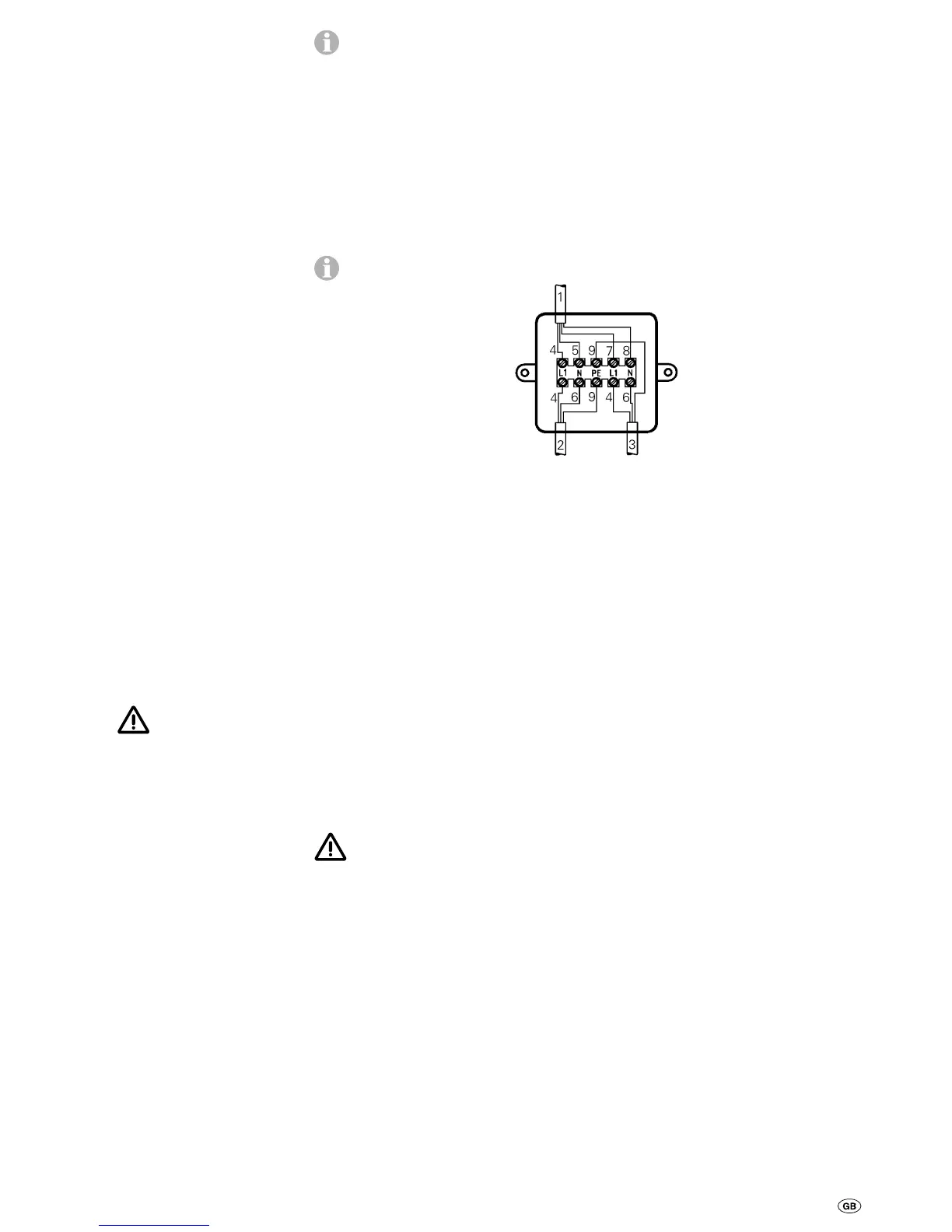

Mount splitting box near to

the appliance – on the vehicle

floor or on the wall (length of

cable: 90 cm).

Connect operating unit cable,

feed lead 230 V, and heat

sleeve cable as shown in the

illustration.

1 = control panel cable

2 = supply 3 x 1.5 mm

2

3 = heating collar cable

4 = brown

5 = green

6 = blue

7 = yellow

8 = white

9 = yellow/green

All cables must be secured

with cable clips.

Function check

After installation, the gas

feed line must be tested for

tightness by the pressure-

drop method. A test certifi-

cate (in Germany, for exam-

ple, in accordance with

DVGW Worksheet G 607 for

motor vehicles or G 608 for

boats) is to be issued.

Then check all functions of

the appliance, as specified in

the operating instructions, in

particular the water content

draining function.

There shall be no claims

under guarantee for dam-

age caused by frost!

The operating instructions

and completed guarantee

card are to be given to the

owner of the vehicle.

Warning

information

The installer or vehicle owner

must apply the yellow sticker

with the warning information,

which is enclosed with the

appliance, to a place in the

vehicle where it is clearly

visible to all users (e.g. on

the wardrobe door)! Ask

Truma to send you stickers,

if necessary.

Loading...

Loading...