10

Inspection and Maintenance

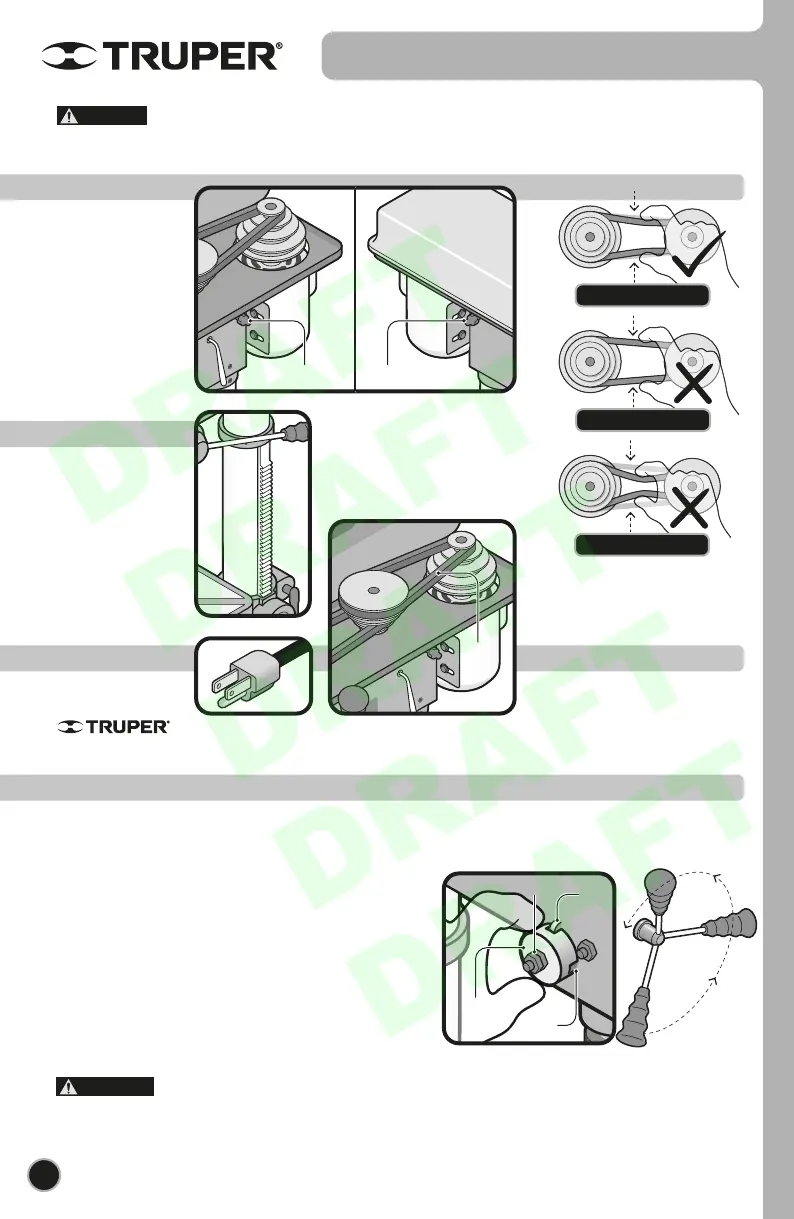

Right-Hand Side

Tension Securing Knob

Left-Hand Side

Tension Securing Knob

Bands

Spindle

Spring Cap

Weekly

Monthly

Each six month

When Needed

Band Tension and

Securing Knobs:

• Check the tension

adjustment in the

securing knobs in both

sides of the drill head

(model TAPI-8 only has

one knob in the

right-hand side of the

drill head).

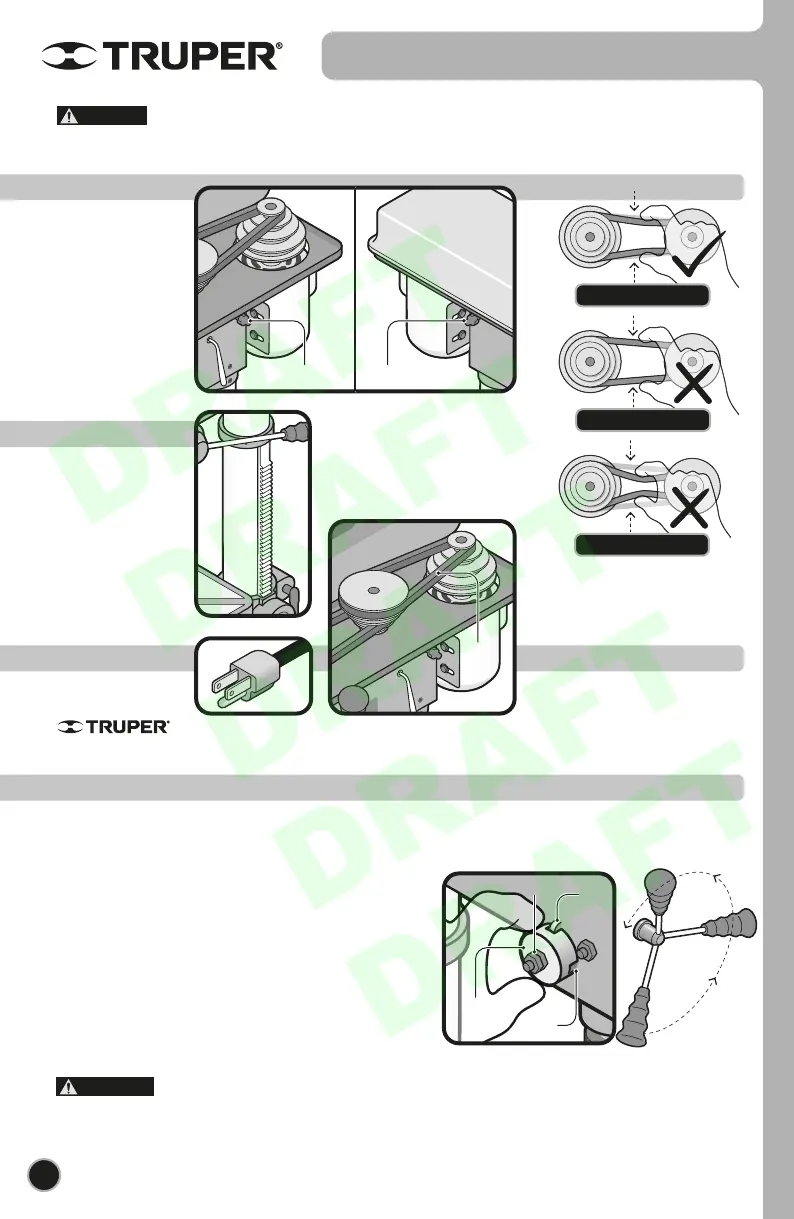

Adjust tension in the star control:

• Hold the spindle spring cap with one hand. Loosen with your

other hand the nuts found in the spring cap. Do not remove the

nuts completely out of the screw.

• Pull out the cap while holding it firmly. Turn it around its axis until

it matches the drill head stop with the next notch of the spring cap.

• Turn the cap clockwise to loosen tension and counterclockwise to

increase tension.

• Verify the notch in the spring cap is in place and then adjust the

nuts. The second nut makes friction with the first one (blind nut). These, shall not touch the spring cap when adjusted.

Too much tension in the star control makes it turn back with force to its original position, which could hit

the operator if not cautious enough.

• Check the bands are duly tense

and correctly adjusted. The band

tension is correct if the bands can

be tightened approximately one

centimeter.

Column and Rack:

• Lubricate the column

using commercial oil.

• Grease the rack with

commercial grease

(For bearing lubrication).

Bands:

• Check the bands inside the drill

head are not porous or worn.

Cleansing:

• Frequently shake de dust out inside the drill motor. Apply cleaning wax to the drill work bench and column to keep them

always clean. Do not remove shavings with your hands. Use a brush.

Electric system:

• Have a

Authorized Service Center check the drill electric system.

To get a safe and faultless operation, as well as significantly extend the useful life of the drill, a regular and

correct maintenance is needed. Make sure the tool is disconnected before inspecting, carrying out maintenance or repairs.

Nuts

Notch

Stopper

Too much tension

Adequate tension

Too loose

Column

Rack

Star

Control

CAUTION

WARNING

ENGLISH

DRAFT

DRAFT

DRAFT

DRAFT

DRAFT

Loading...

Loading...