®

OPERATOR’S MANUAL

MAINTENANCE MANUAL

PARTS LIST

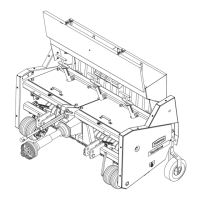

60” Inch Seeder

Product Number 85851

Starting Serial Number P00801

PATENT PENDING

Manual Number 665365 Rev B

DANGER -

IF INCORRECTLY USED THIS MACHINE CAN CAUSE SEVERE INJURY.

THOSE WHO USE AND MAINTAIN THIS MACHINE SHOULD BE TRAINED IN ITS

PROPER USE, WARNED OF ITS DANGERS, AND SHOULD READ THE ENTIRE MANUAL

BEFORE ATTEMPTING TO SET-UP, OPERATE OR SERVICE THE MACHINE.

TURFCO MFG. INC.

1655 101st. Avenue NE

•

Minneapolis, MN 55449-4420 USA

Phone (763) 785-1000

•

FAX (763) 785-0556

•

www.turfco.com

2011 Turfco Mfg., Inc.

TURFCO

®

60” Inch Seeder