Addendum: Clean-In-Place System

E09 TD-4100XD

A-4 E09 TD-4100XD Oil In Water Monitor

Clean-In-Place Addendum

PN 106169

Rev B

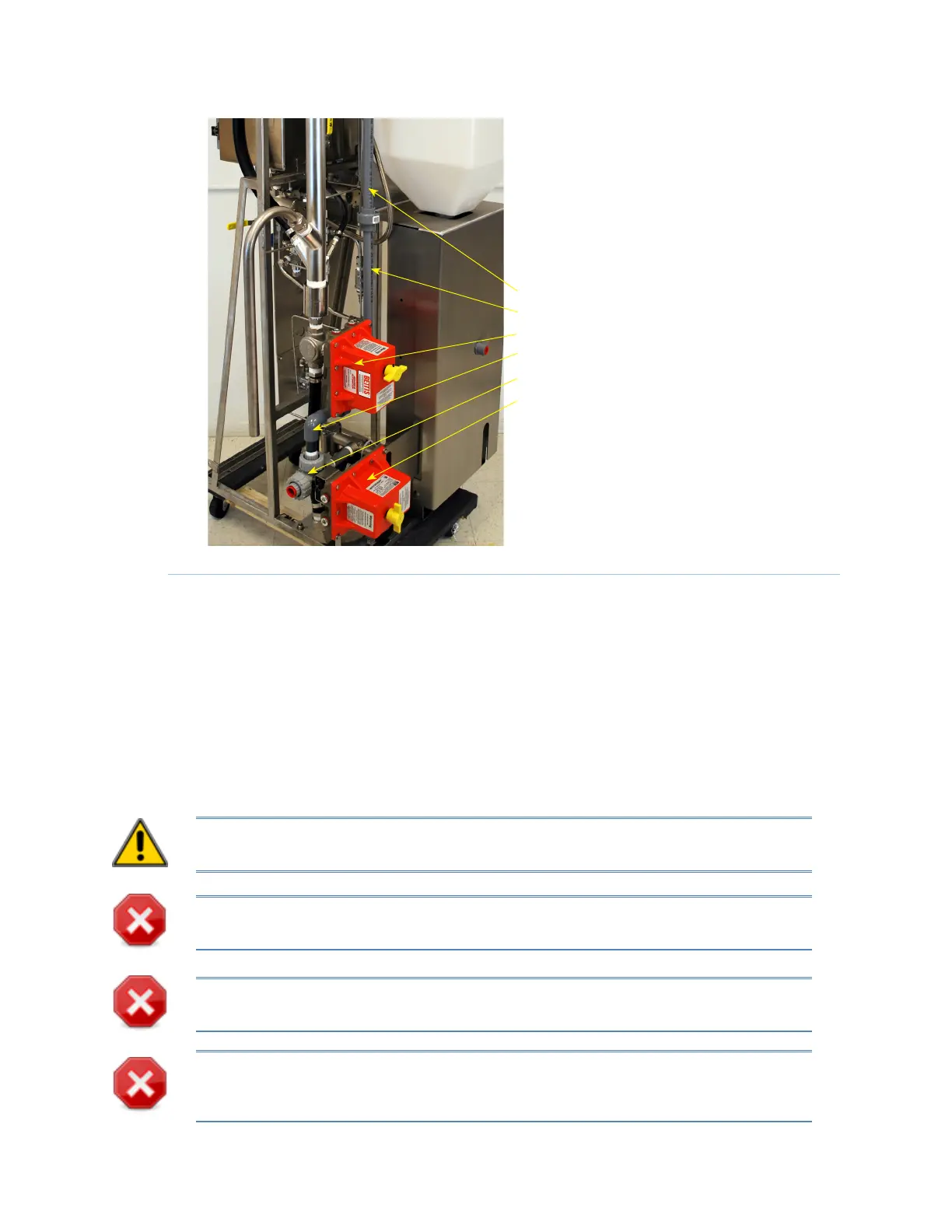

The nished CIP system showing the parts requiring

assembly.

Piece 3

Piece 4

Piece 5

Piece 2

Piece 1

Piece 6

A.1.1 DESIGN INFORMATION

• Power to the pump and valve actuators is supplied by the input mains at 115 VAC.

• The CIP pump can be set for 115 VAC or 230 VAC but must be set at 115 VAC for use with this

monitor.

• Maximum working pressure of cleaning solution pump: 75 psig [517 kPa(g)].

• Cleaning solution maximum pumping capacity: about 18 U.S. gal/min [68 L/min] .

The automatic cleaning system automates all sample valves associated with the monitor. The valves

are directed to avoid cross contamination of uids during the cleaning process. During power failures,

valves will remain in their last state. During start-up after a power failure, the valves will be directed to

the process. During stabilization periods, the valves are directed to the outlet.

WARNING: Although the CIP system pump is dual voltage, it must be wired for 115 VAC operation

with this monitor.

CAUTION: Repair or replace worn or damaged parts immediately. Do not alter or modify the

cleaning solution pump.

CAUTION: Do not block or restrict the cleaning solution tank vent, which is located in the center of

the tank cover. This vent must remain open to atmosphere.

CAUTION: The cleaning solution must be compatible with the process downstream of the monitor

since a portion of the cleaning solution may be directed into the monitor’s drain line when the

cleaning cycle is nished.

Loading...

Loading...