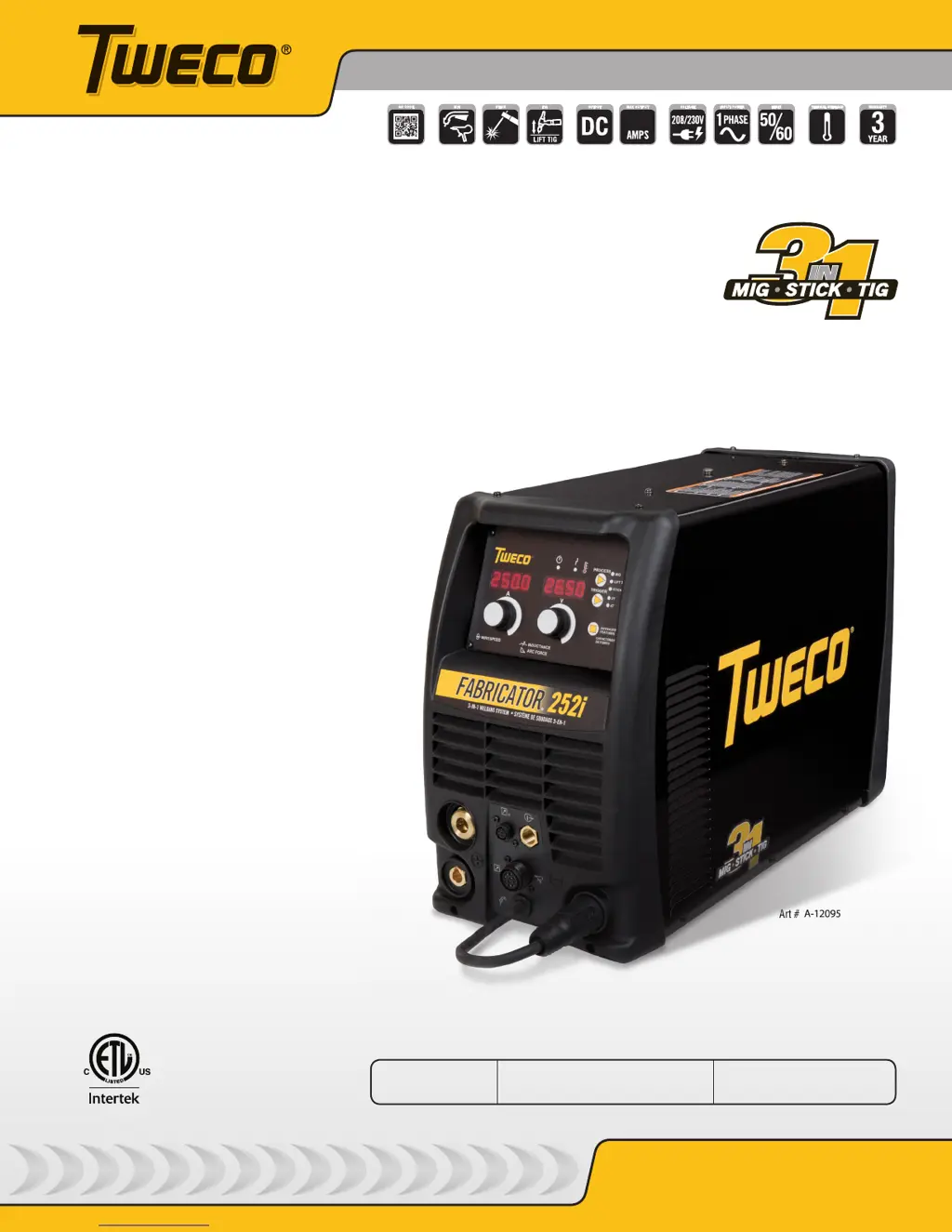

What to do if my Tweco FABRICATOR 252i Welding System has inconsistent wire feed?

- ZznavarroAug 16, 2025

Inconsistent wire feed can be caused by several factors: * If the wire spool brake is too tight or too loose, adjust it accordingly. * Using a worn or incorrect feed roller size requires using a feed roller matched to the size you are welding. * Misalignment of inlet/outlet guides requires adjustment. * A liner blocked with swarf can be caused by excessive pressure applied to the pressure roller adjuster. * An incorrect or worn contact tip can cause arcing inside the tip, jamming the wire, so replace if needed. * Poor work lead contact to the workpiece will heat up the connection point, reducing power at the arc. * A bent liner will cause friction between the wire and the liner, reducing wire feed ability.