TFP1326

Page 17 of 22

Step 6. Reset the electric detection

system in accordance with the manu-

facturer’s instructions to de-energize

the Solenoid Valve (N), and proceed

as follows:

• Water should cease draining from the

Solenoid Valve (N).

• Pressure will then build up in the

DV-5A Diaphragm Chamber.

• After system pressure is restored

in the DV-5A Diaphragm Chamber,

inspect the Solenoid Valve (N) for

leaks at the drain tube. Any leaks

must be corrected before proceed-

ing to the next step. The Solenoid

Valve (N) discharges water into the

riser and must be drained at the con-

cluson of this test.

Step 7. Partially open the System

Main Control Valve (B). Slowly close

the Main Drain Valve (D) as soon as

water discharges from the Main Drain

Valve (D). Observe the Automatic Drain

Valve (F) for leaks. If there are leaks,

determine/correct the cause of the

leakage problem. If there are no leaks,

the DV-5A Valve is ready to be placed

in service and the System Main Control

Valve (B) must then be fully opened.

Internal Valve Inspection

Once every five years during the annual

operational test procedure and prior

to the DV-5a Valve being reset and

with the DV-5a Valve de-pressurized,

the interior of the DV-5a Valve must

be cleaned and inspected for wear

and damage. Damaged or worn parts

must be replaced. (Replacement of the

Diaphragm every ten years is recom-

mended, or more frequently if inspec-

tions and/or wear and tear warrant

more frequent replacement.)

NOTICE

The Diaphragm Cover may be removed

between Steps 4 and 5 of the reset-

ting instructions, since at that point the

DV-5a Valve should be de-pressurized

as evident by a zero gauge reading on

the Diaphragm Gauge (K) and Water

Supply Gauge (J), as well as no water

discharging from the Automatic Drain

Valve (F).

Ensure that the Diaphragm Supply

Valve (P) and the System Main Control

Valve (B) are closed before removing

the cover.

To perform internal valve inspection

between Steps 4 and 5 of the Valve

Setting Procedure, remove the dia-

phragm cover as follows:

Step 1. Close the Inverted Flare Shut-

Off Valve (R).

Step 2. Remove the Copper Tube

Fitting between the Diaphragm Supply

Valve (P) and the Inverted Flare Shut-

Off Valve (R).

Step 3. Loosen the union securing the

Solenoid Valve (N).

Step 4. Loosen and remove the union

between the Diaphragm Cover and the

trim and remove the trim.

Step 5. Remove the Diaphragm Valve

Cover hardware, then slowly remove

the Diaphragm Cover and perform

internal valve inspection. Clean the

valve interior and replace parts as

necessary.

After cleaning and inspecting valve

interior, and replacing parts as nec-

essary, reinstall the Diaphragm Cover

by completing the following steps to

assure the Diaphragm Cover Fasteners

are uniformly and securely tightened.

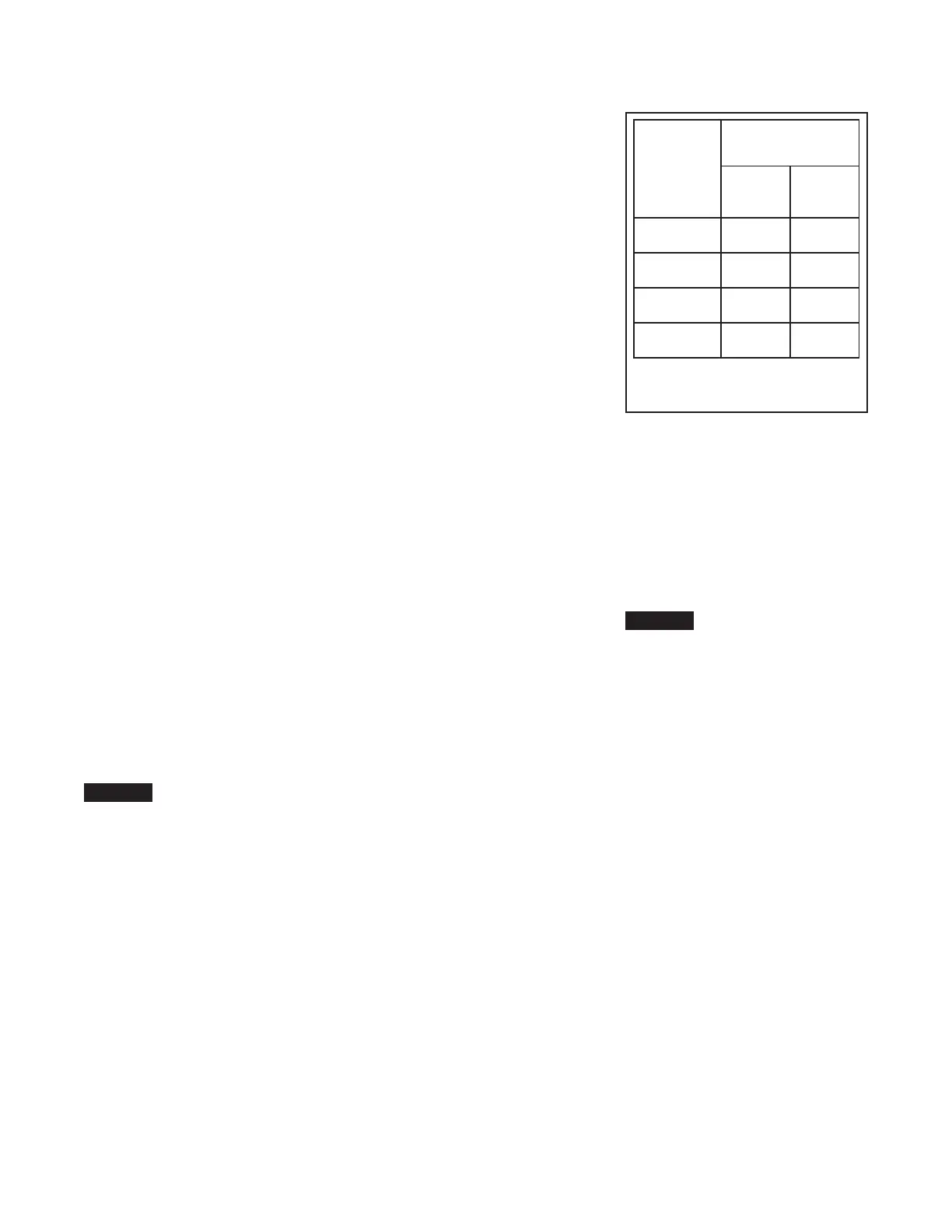

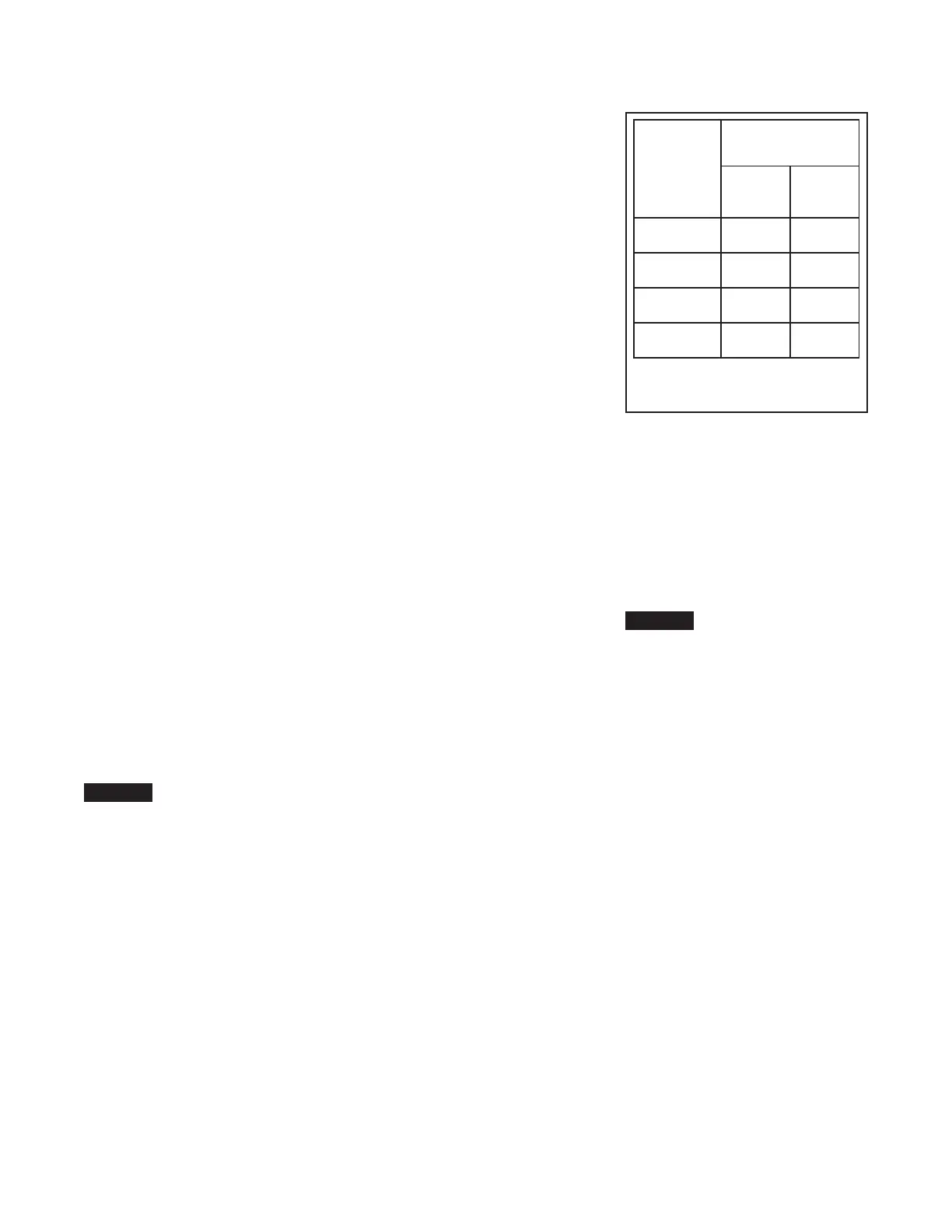

Step 1. With reference to Figure 1,

ensure that the Diaphragm is properly

oriented and that the proper hardware

arrangement is utilized when assem-

bling the Diaphragm Covers. The hard-

ware arrangements differ depending on

the size of the DV-5a Valve.

Step 2. By first using the Long Hex

Bolts, support of the Diaphragm Cover

will be provided before installing the

Short Hex Bolts. Align Diaphragm in

proper orientation with Valve Body, and

then align Diaphragm Cover in proper

orientation with Valve Body. Hand-

tighten all fasteners.

Step 3. Using crossdraw sequence

to assure uniformity, wrench-tighten

Long Hex Bolts and Short Hex Bolts

to appropriate torque values. Repeat

crossdraw sequence two to three

times at incremental torque valves

until reaching the torque valves found

in Table C.

Step 4. Inspect to assure all Hex Bolts

are securely tightened.

Step 5. Using the union, the trim to the

Diaphragm Cover.

Step 6. Using the union, secure the

solenoid Valve (N).

Step 7. Replace the Copper Tube

Fitting between the Diaphragm Supply

Valve (P) and the Inverted Flare Shut-

Off Valve (R).

Step 8. Ensure that the unions and flare

fittings are securely tightened.

Step 9. With the Diaphragm Supply

Valve (P) closed, fully open the Inverted

Flare Shut-Off Valve (R) stainless steel

screw (approximately ½ in.) until resis-

tance is met so as not to break the

internal roll-pin. The internal roll-pin

stops the removal of the Inverted Flare

Shut-Off Valve (R) stainless steel screw.

Step 10. Proceed to step 5 of the Valve

Setting Procedures section in this data

sheet.

NOTICE

If the water supply contains chemicals

which tend to attack a polyester fabric-

reinforced, EPDM rubber or the five

year inspection indicates a build-up of

debris within the DV-5A Valve that could

affect its proper operation, then the

frequency of the internal valve inspec-

tion procedure must be appropriately

increased.

With reference to Figure 1, make

certain that the Diaphragm is correctly

oriented; otherwise, the DV-5A Valve

cannot be properly set.

Under-tightening the Diaphragm Cover

Bolts can result in internal and external

leakage.

Use only TYCO replacement fasteners

as specified in Figure 1.

Do not apply adhesives, lubricants, or

other substances to the Diaphragm or

Valve Body.

Nominal

Valve Sizes

ANSI

Inches

(DN)

Torque

lb-ft

(N∙m)

Nuts

Short

Hex

Bolts

3

(80)

188

(254,9)

150

(203,4)

4

(100)

396

(536,9)

316

(428,4)

6

(150)

265

(359,3)

212

(287,4)

8

(200)

545

(738,9)

436

(591,1)

TABLE C

DIAPHRAGM COVER BOLTS

MINIMUM TORQUE

Loading...

Loading...