2008 9 DSTOPTRS

Using the cable and handle provided at the left side inspection door, open the separa-

tor door and lock in the second cable bead position. Step the dump door closed as when

opening. Failure to open the separator door when washing out the hopper can cause de-

bris to collect in the separator chamber, inhibiting the separator to spin out dust, there-

fore causing rapid wear of the blower housing components.

After using the hopper deluge system, a hand held high volume/high pressure hose

should be used to remove any debris left by the hopper deluge.

B. DST-6 COMPONENTS

Uncouple the suction transition and using

the hand held wash hose, wash out the

suction tube leading from the pick-up head

to the hopper inlet. The vacuator manifold

rock screen must also be washed clean.

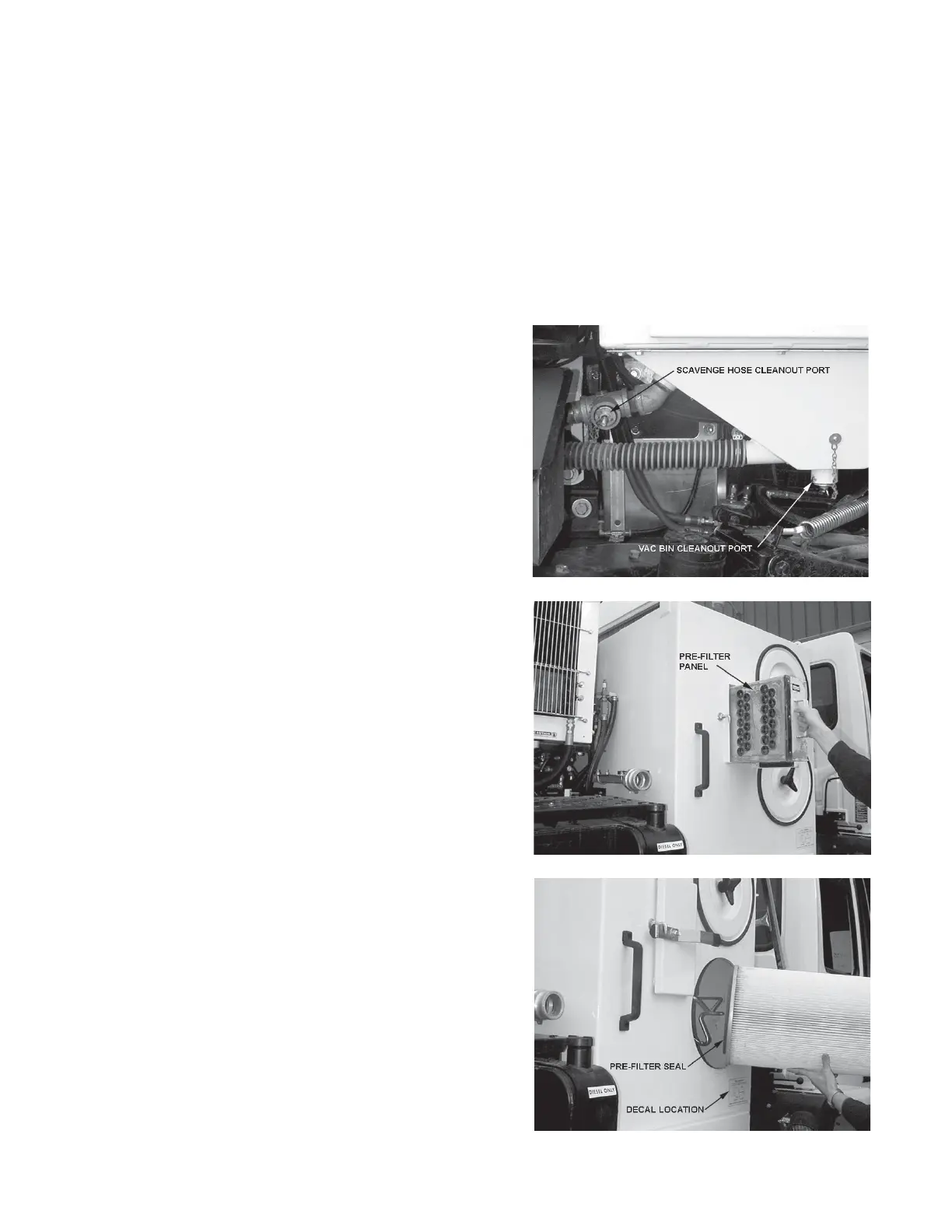

Remove the cleanout plugs from the vac-

uator bin and the scavenge hose cleanout

tee (Photo M01378). Back flush the vac-

uator hose and scavenge hose observing

water running out the cleanout ports. Close

the vacuator manifold ball valve once the

vacuator hose has been washed out. (Pho-

tos M01369 & M01370)

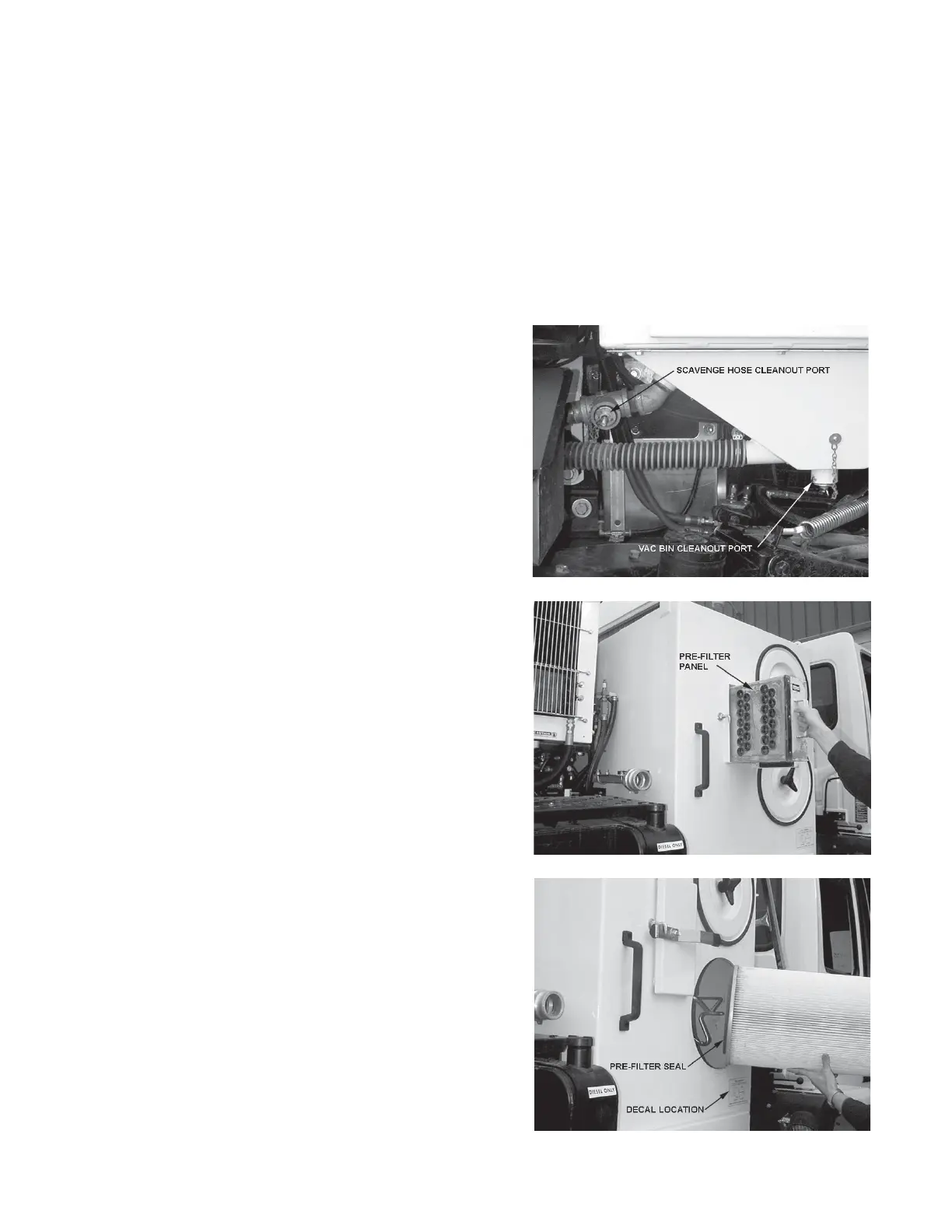

Remove the pre-filter panel from the DST-6

box and thoroughly clean making certain

to remove all dirt and grass debris from the

small tubes on the panel face. Clean out

the scavenge bin which is the area in the

DST-6 box just under the pre-filter. The

scavenge hose must be flushed out and

clear before reinstalling pre-cleaner. (Photo

M01371)

C. DST-6 FILTERS

The DST-6 uses special filters to clean the

exhaust air before it is released into the

atmosphere. The filters utilize a PTFE mem-

brane which gives the filter good release

characteristics as well as protection from

water damage. The filters are actually wa-

terproof and can be washed by low pres-

sure hose and returned to the sweeper with-

out drying. Should mud dry on the filters,

soak the filter until the mud softens, then

wash off with low pressure water hose.

(Photo M01372)

The filter PTFE membrane is fragile and

over-servicing the filter can cause the PTFE

membrane to fail. Care should always be

used when handling the filter as the PTFE

M01371

M01372

M01378

Loading...

Loading...