DSTOPTRS 10 2008

membrane is on the exterior side of the filter and can be easily scraped off. Use

care not to drop the filter or otherwise damage the filter’s metal ends.

ROUTINE MAINTENANCE

A. HOPPER SEALS

Even a small seal leak can reduce sweeper efficiency, operator should be diligent by

inspecting sweeper seal condition daily! To check seal, slip a small piece of paper,

such as a dollar bill, between the door seal and jam. Latch the door and pull on the

paper. The paper should be clamped between the door seal and jam very tightly

indicating a good seal. Do this at all four corners and in the middle of the door to

make sure there is a good seal all around.

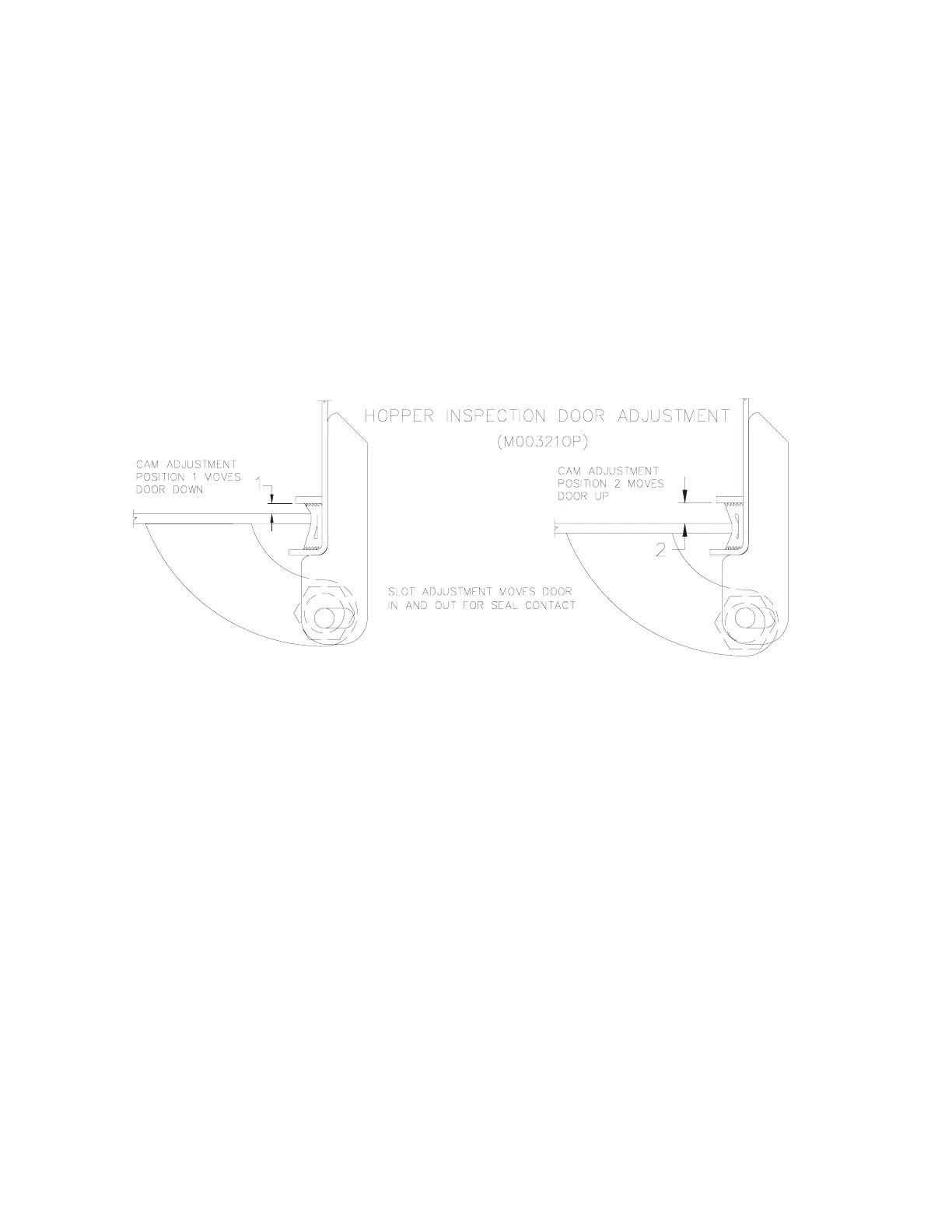

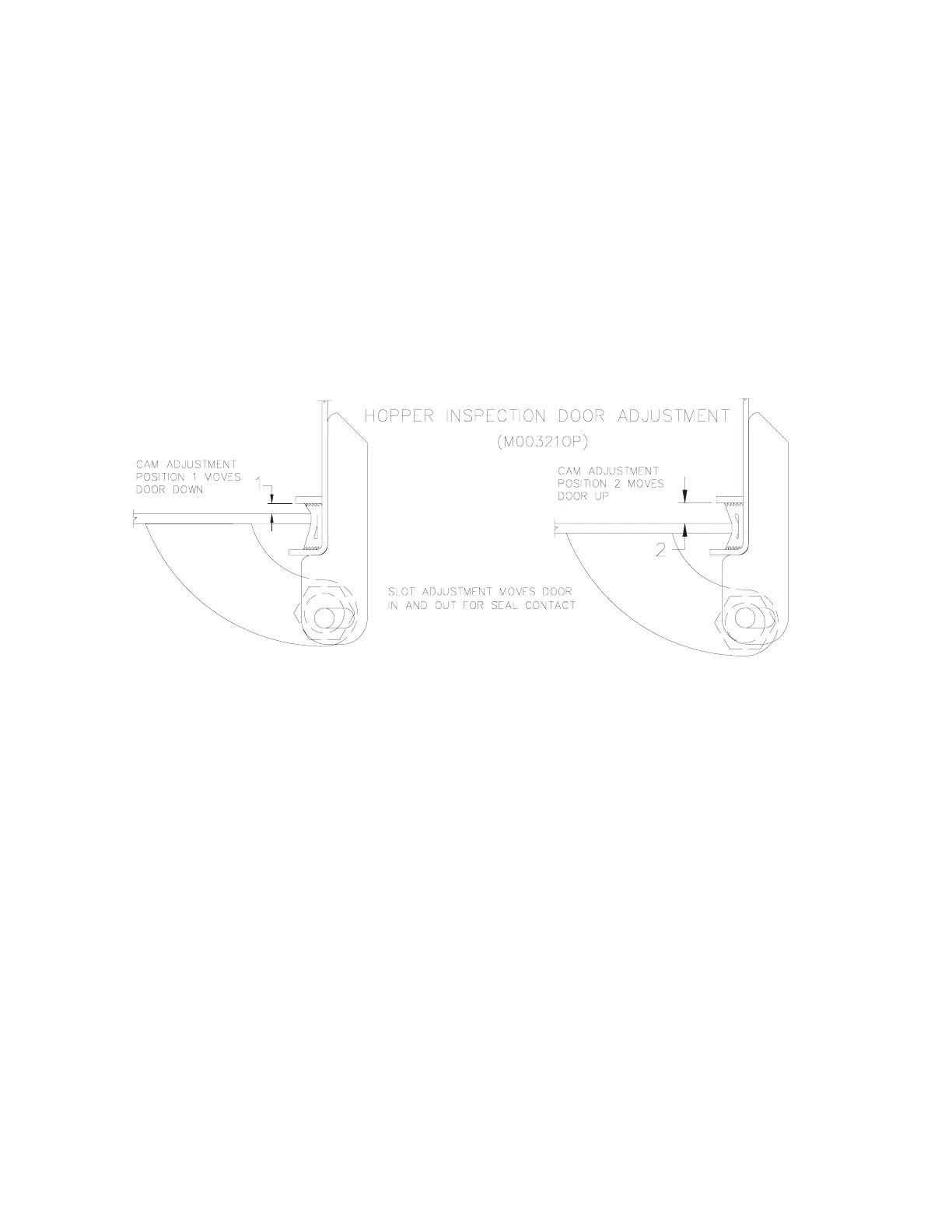

1. Inspection Door Seal - See below for proper setting and adjustment of inspection

door.

Refer to Drawing M00321OP. Each inspection door should be airtight. Normally,

once a door has been adjusted, simply replacing a torn or worn seal usually

solves most problems. However, if needed, adjust door by loosening the bolts

and rotating eccentric cam for up and down alignment and adjust slots for in and

out to make contact with the seal all the way around the door. Add service life to

door seals by leaving doors open when sweeper is parked and not in use.

2. Hand Hose Door Seal - The optional hand hose shutter door must be closed

when sweeping. Leaving the hand hose attachment connected to the hopper will

cause poor performance and excessive dust when sweeping. Adjust “J” bolt in to

tighten door for better seal.

3. Dump Door Seal - The large dump door of the TYMCO Model DST-6 uses a large

rubber seal glued into the dump door channel of the hopper. Add service life to

the dump door seal by leaving the door partially open when the sweeper is parked

and not in use.

4. Transition Seal - Two replaceable transitions adapt the sweeper’s square hopper

openings to the round suction and pressure hoses leading to the pick-up head. A

rubber sealing gasket is used to produce an airtight fit between the transition and

the hopper opening.

The pressure transition is bolted on for safety and the suction transition has a

quick disconnect design for easy access and cleaning. Longer service life of the

transition can be obtained by rotating the transition 180 degrees once a month for

more even wear.

Loading...

Loading...