DSTOPTRS 18 2008

2. Hopper Seals - The hopper must be maintained air tight for the sweeper to perform

adequately. Daily inspect the inspection door seal, dump door seal, transition seals

and, if hand hose attachment is used, the hand hose door seal. If any section of the

seal material is missing, replace the seal. Refer to Page 9 for seal locations.

3. Hopper Screen

- The large screen found inside the hopper is very important for pre-

venting large debris from entering the separator and blower assembly. Inspect the

screen daily. If any large holes are found, do not operate sweeper until screen has

been repaired or replaced. Refer to Page 9 for screen location. Once every 500

hours the hopper screen should be removed from hopper and area above separator

should be cleaned thoroughly. This area is called the separator inlet. If allowed to

become stopped up, the sweeper efficiency is drastically reduced. Refer to Page 9

for separator inlet location.

4. Skimmer hood

- Inside the Model 600 hopper is a shielded area attached to the sep-

arator door. This shielded area is formed by what is called the Skimmer Hood and

is designed to create a void area into which the fine dust removed by the separator

skimmer slot can accumulate. The skimmer hood protects the separator skimmer

slot from being choked off by debris being deposited in the hopper during operation.

IMPORTANT: Always close the separator door before closing the dump door.

Opening the dump door retracts the raker plate so that the sepa-

rator door latches properly when closed.

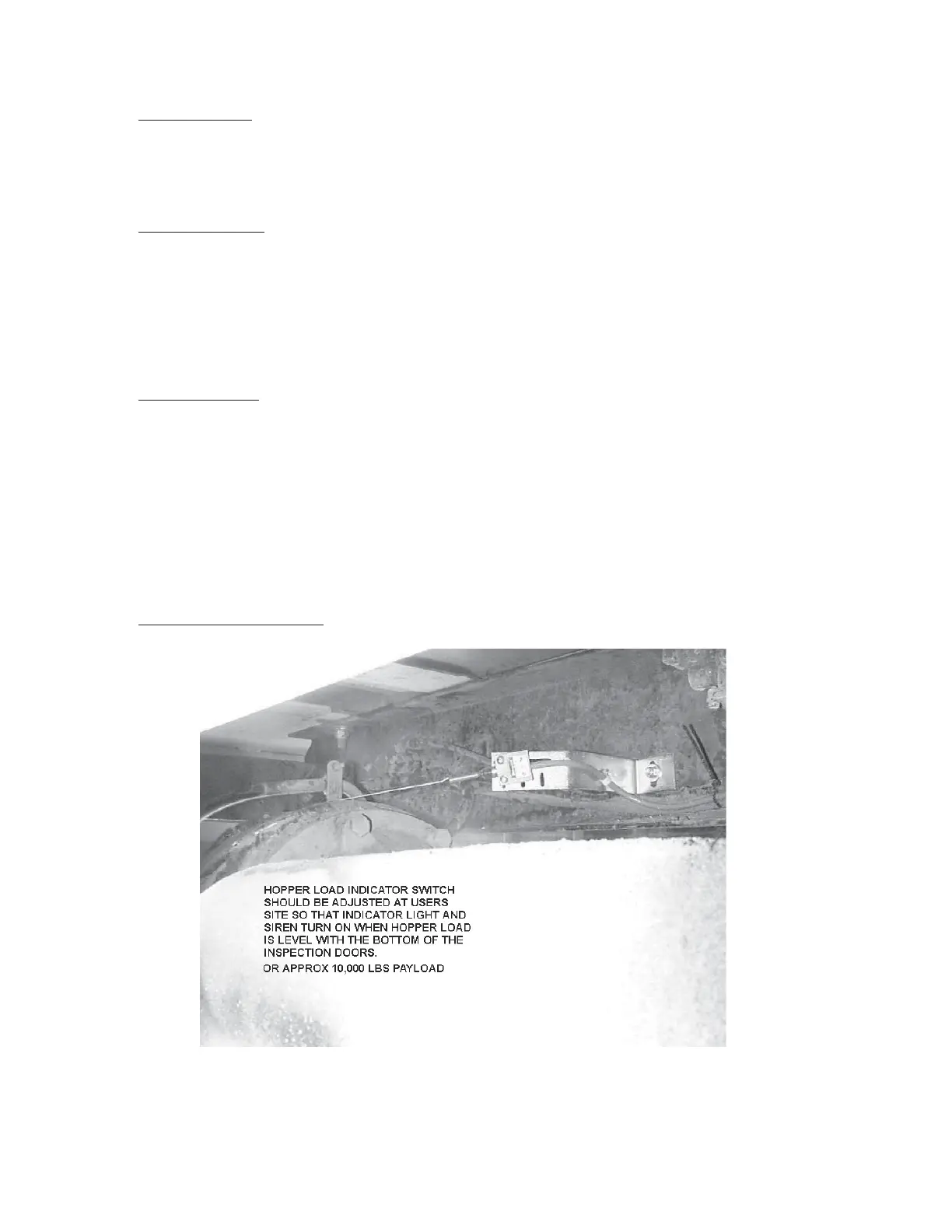

5. Hopper Load Indicator

- See Photo M01380.

M01380

Loading...

Loading...