DSTOPTRS 32 2008

4. Insert 5/8" bolts and thread them into the segment. Do not over tighten bolts or plas-

tic segment may be stripped requiring longer bolts and the use of nuts on bottom.

5. Remove segment clamp and install 3/8" center support bolt.

6. Once all four segments have been installed, check spring tension and tilt setting.

C. SERVICE

1. Torque Motor Shaft - routine service of the gutter broom requires daily inspection

of the torque motor output shaft. Remove any buildup of grass, string, cassette

tape, etc. that has wound around the shaft. Failure to do so will cause rapid failure of

the high pressure shaft seal and possible damage to output shaft. If oil is observed

to collect in disc, check torque motor hose fitting tightness; if OK, then torque motor

high pressure seal must be serviced. Refer to Service & Parts Manual for rebuild

procedure.

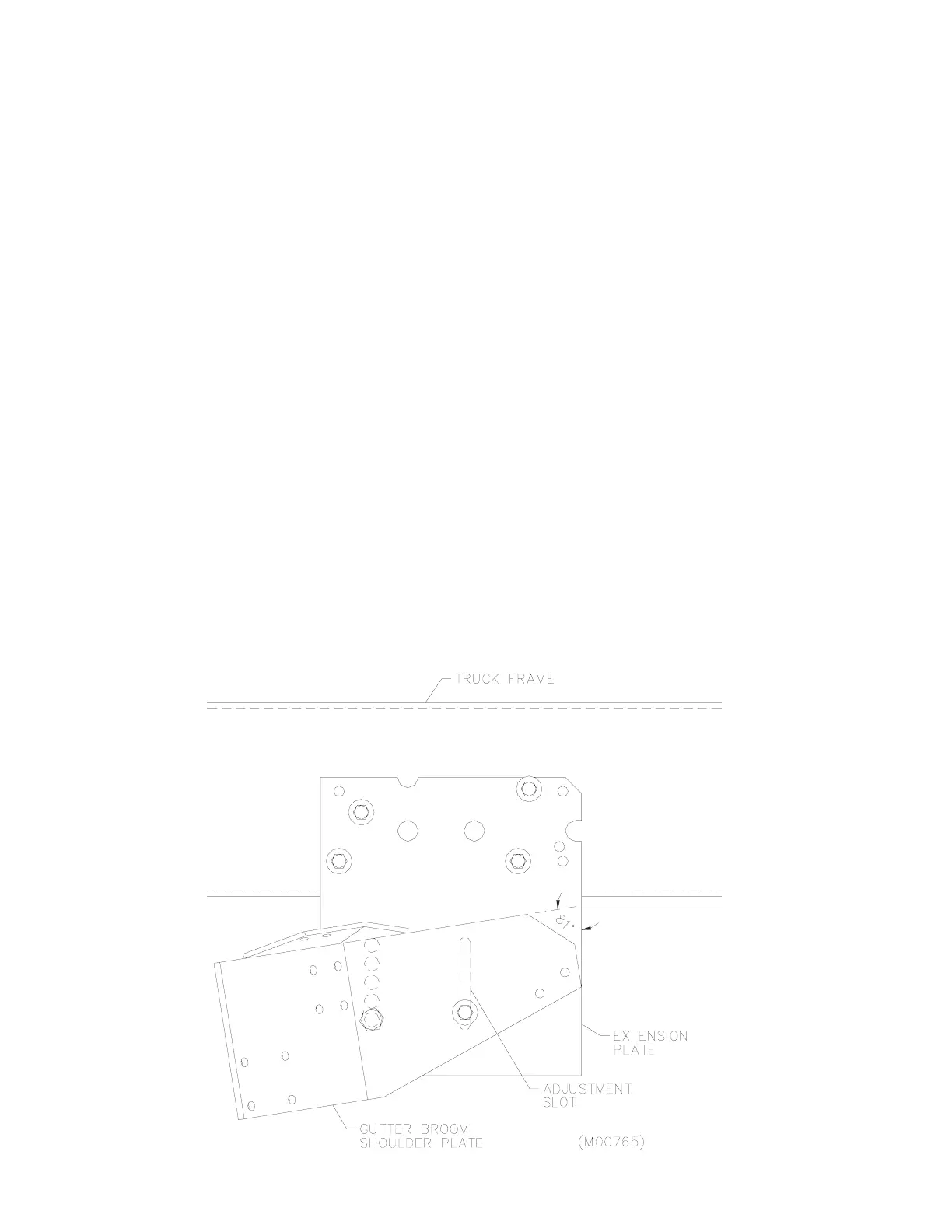

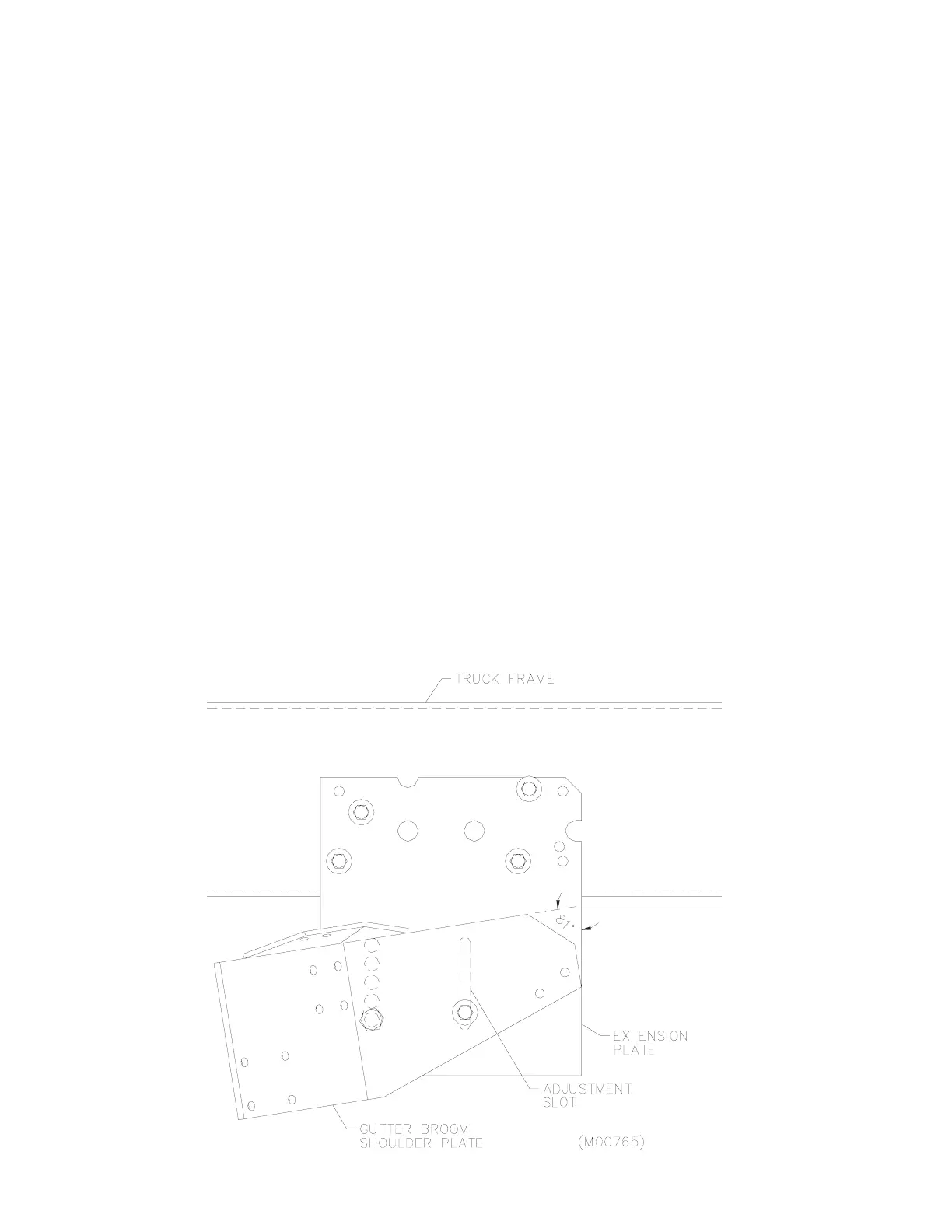

2. Shoulder Plate Setting - the gutter broom mount plate is bolted to the truck chassis

extension. The gutter broom mount plate referred to as the shoulder plate is ad-

justed so that when the hydraulic cylinder retracts the gutter broom it also causes

the broom to raise. Should this plate get out of adjustment, the broom may retract

but not raise. Two bolts hold this plate in position; one ¾" bolt requiring a 1-1/8"

wrench, and one ½" bolt requiring a ¾" wrench and socket. With the gutter broom in

the DOWN position and off, set the shoulder plate as shown in the drawing.

NOTE: If shoulder plate is set with too much forward slope, the gutter broom will

hit the bottom of the cab or step when raised.

600

SHOULDER PLATE SETTING

(M00765)

Loading...

Loading...