66

Crankcase ventilation system

The system maintenance includes a periodic check of the

hermetic-tightness of joints and cleaning gum residue off of the

system components.

In case of increased oil consumption for burn-out loss and

occurrence of black smoke out of the exhaust pipe, check the

crankcase ventilation system for proper condition (clogging of

channels).

The crankcase ventilation system proper condition is checked

using the water piezometer connected to the crankcase via the

oil level indicator tube.

In the crankcase of an idle running engine (with crankshaft

rpm minimum to maximum), there shall be negative pressure

of 1-14 mbar (10-140 mm WG).

If oil traces appear on the joint between the turbocharger

and the inlet pipe, check the crankcase blow-by gases pressure.

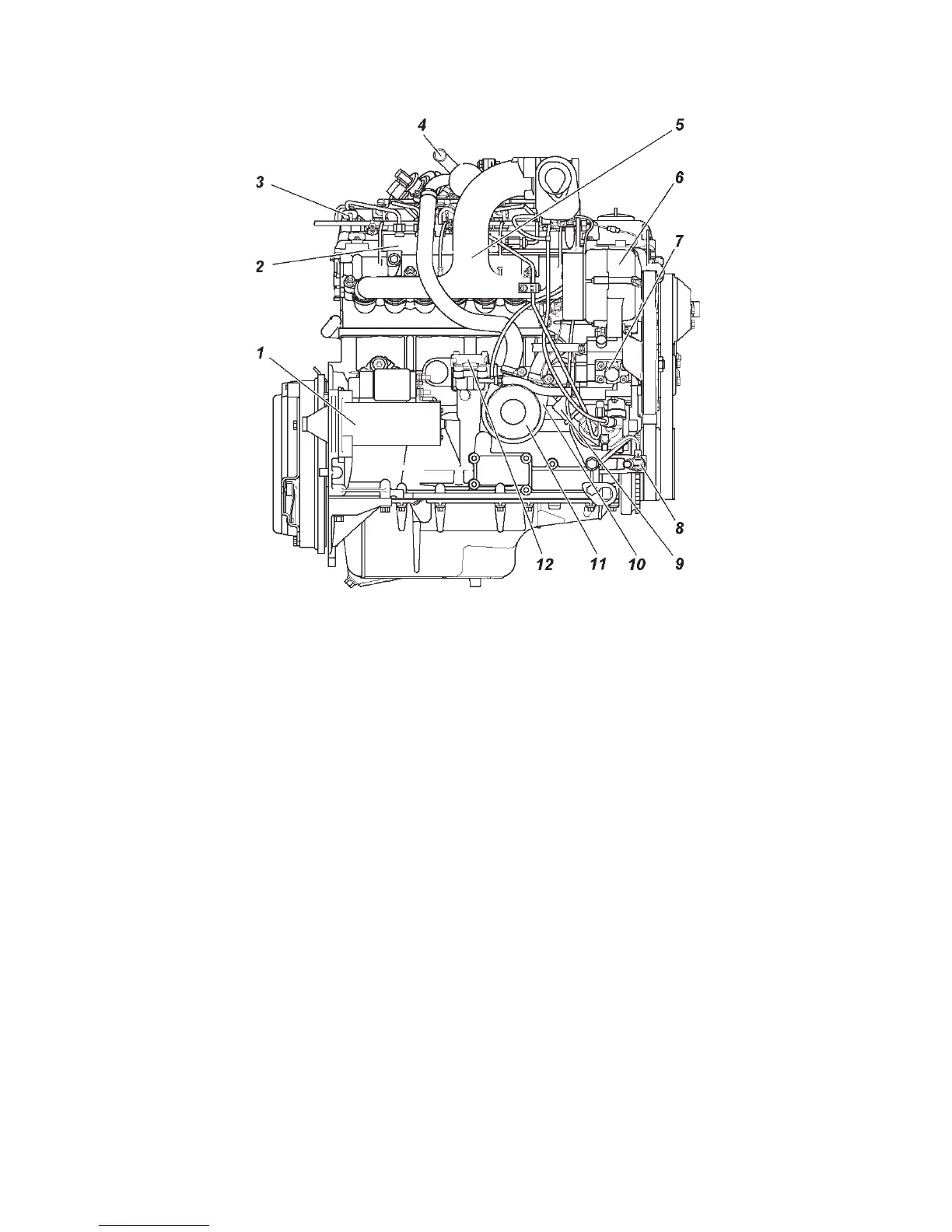

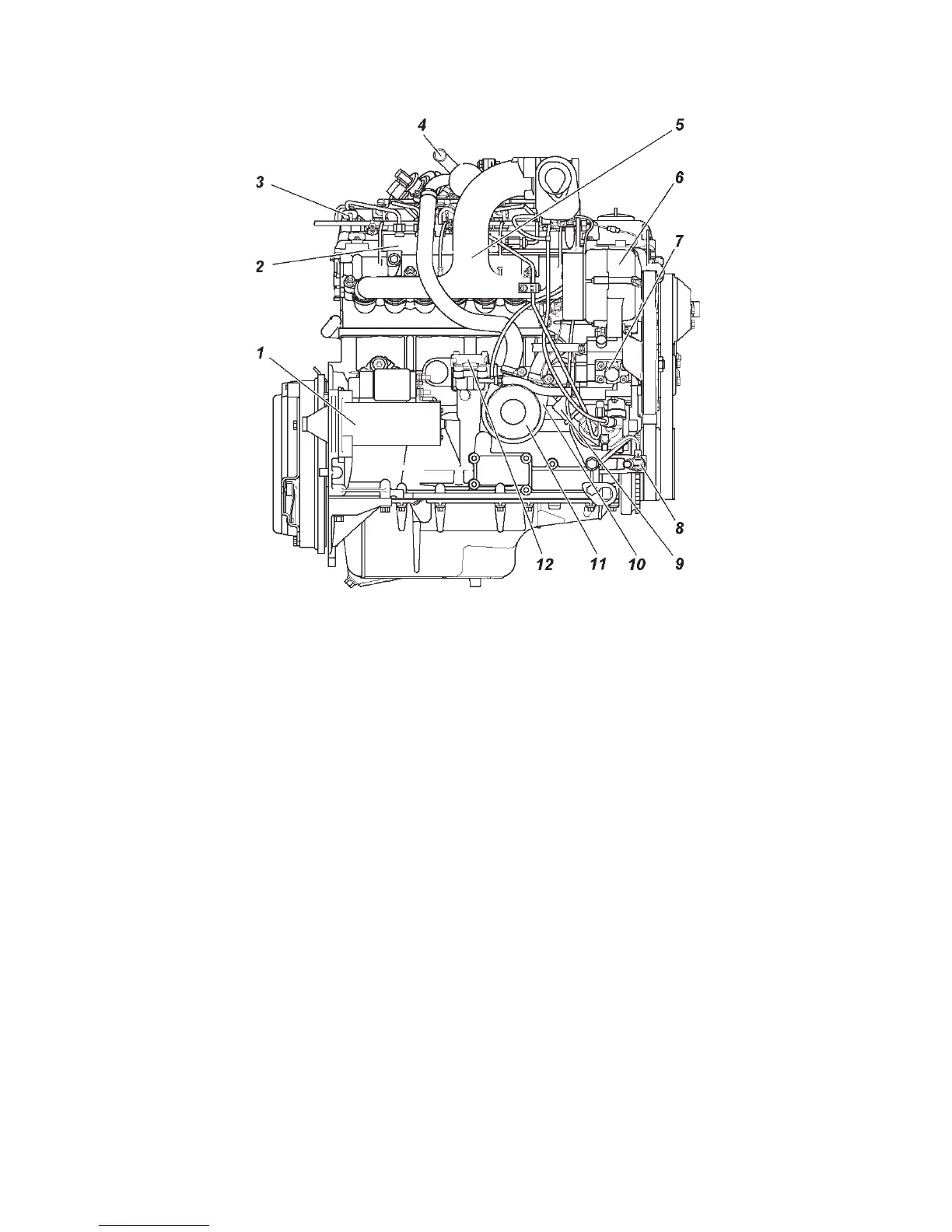

Fig. 9.12. ZMZ-51432 engine (right-side view):

1 — starter; 2 — fuel rail; 3 — phase sensor; 4 — pipe of cooling fluid removal

to the heater; 5 — inlet pipe; 6 — generator; 7 — high-pressure fuel pump

(HPFP); 8 — timing sensor; 9 — pressure sensor; 10 — liquid-oil heat exchanger;

11 — oil filter; 12 — oil pump drive cover

Loading...

Loading...