www.ultraoptics.com page 1

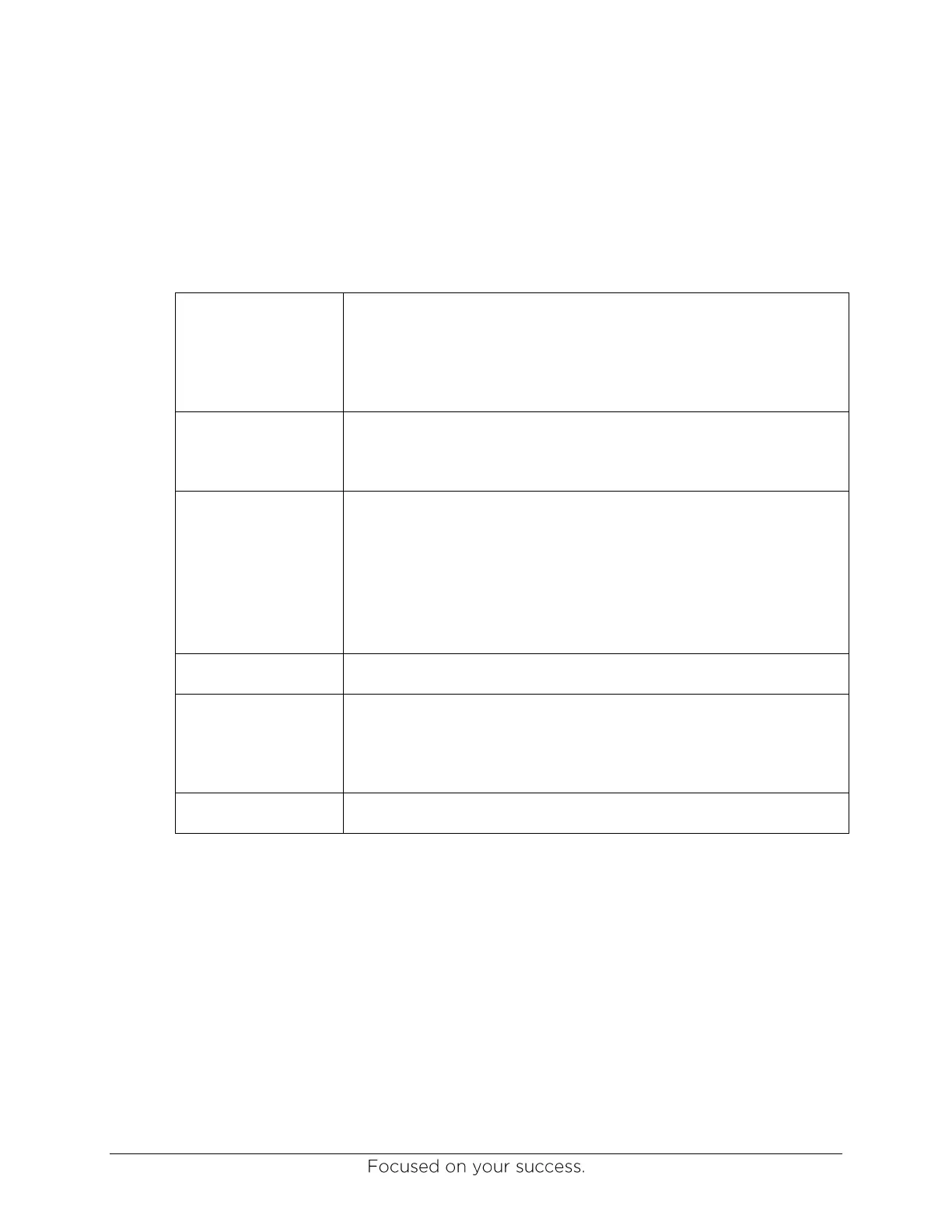

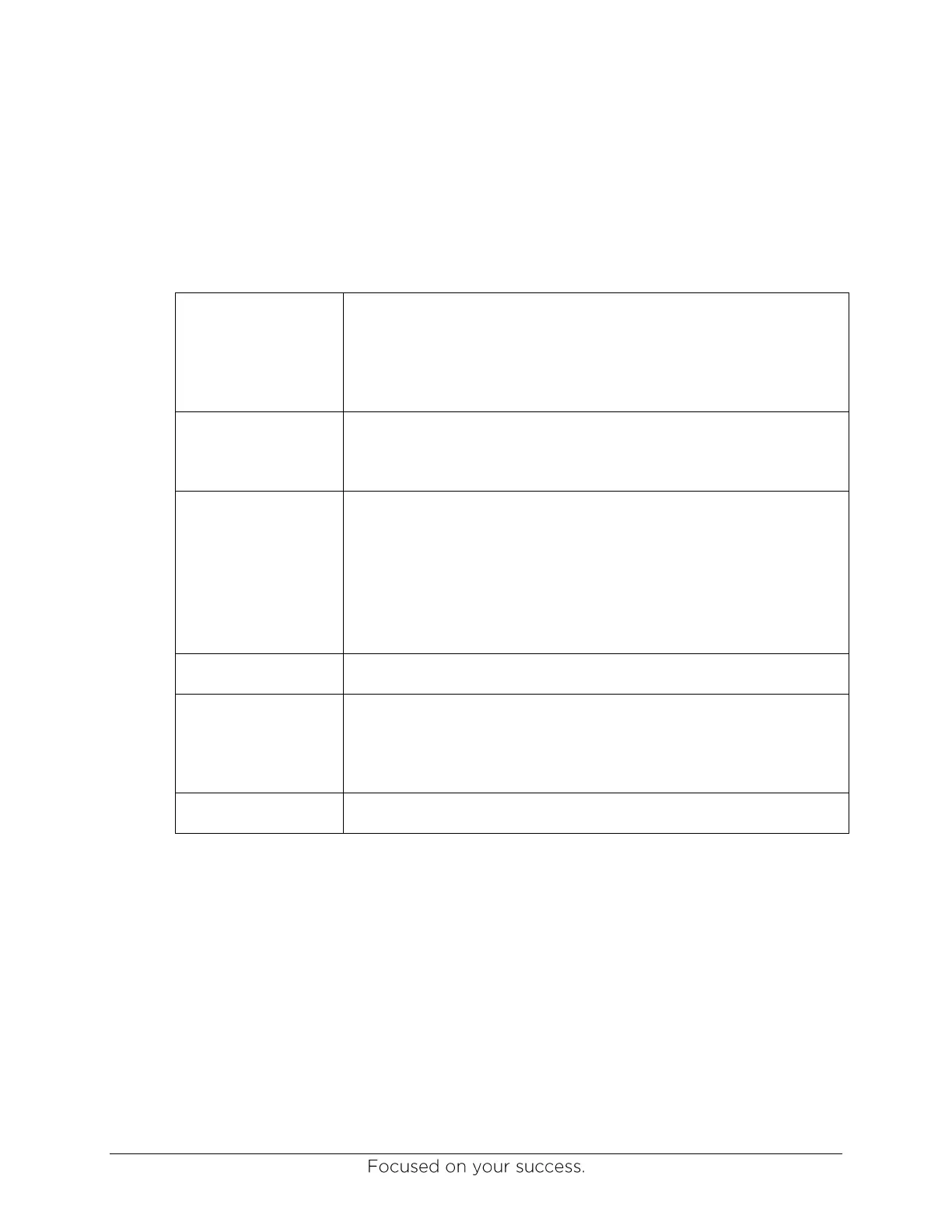

Required Utilities

The following facility utilities are required to operate the Mini2. The provisions for these facilities

are the responsibility of the customer and are not included in the scope of supply for this

machine.

The machine should be installed in a location that is accessible

for easy disconnect of power and has good ventilation with an

air exchange of 4-5 times per hour. It should be located in a low

traffic area to minimize possible dust contamination. While it is

not necessary to install the Mini2 in a clean room, it is not a

good idea to place it near a lens edger either.

Coating Unit

21” D x 25” W x 36” H

Cure Unit

25” D x 16” W x 13” H

Coating Unit

115 VAC, 5 amp circuit required. Machine is supplied

with a grounded three-prong receptacle, OR

One single phase 220 VAC/5A circuit.

Cure Unit

115 VAC, 15 amp circuit required. Machine is supplied

with a grounded three-prong receptacle, OR

One single phase 220 VAC/12A circuit.

80 psig, 10 cfm. The connection on the machine is a 1/4” quick

connect

Consumption of 7.6 L/hr at periodic rates of 0.3 L/min of

deionized water flow rate with ≥ 1 megaohm resistivity. The

machine is supplied with a reservoir that needs to be

periodically filled by the user. The pH value should be greater

than 4.9 and less than 9.1.

The machine is supplied with a drain reservoir that needs to be

periodically dumped by the user.

Loading...

Loading...