-21-

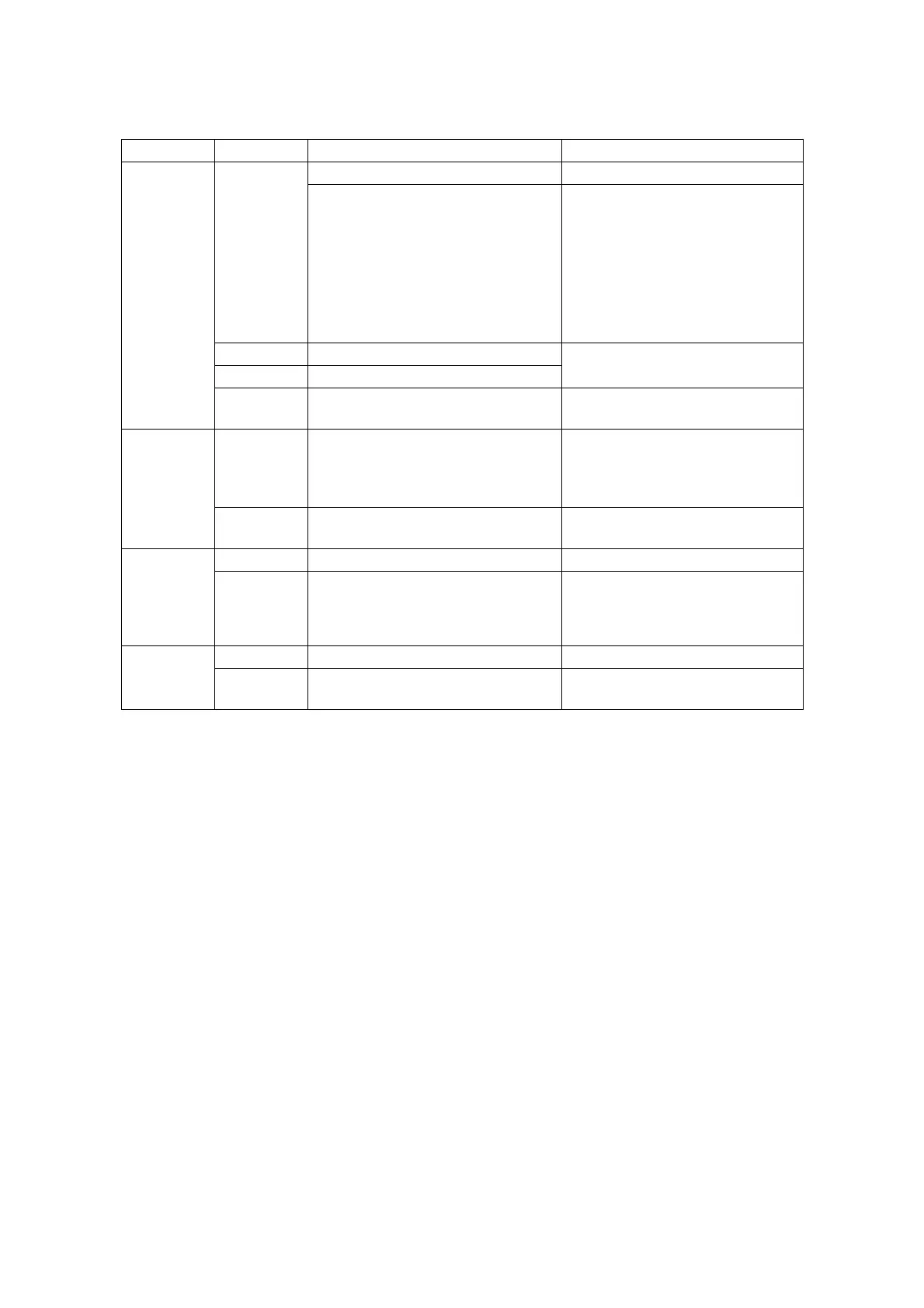

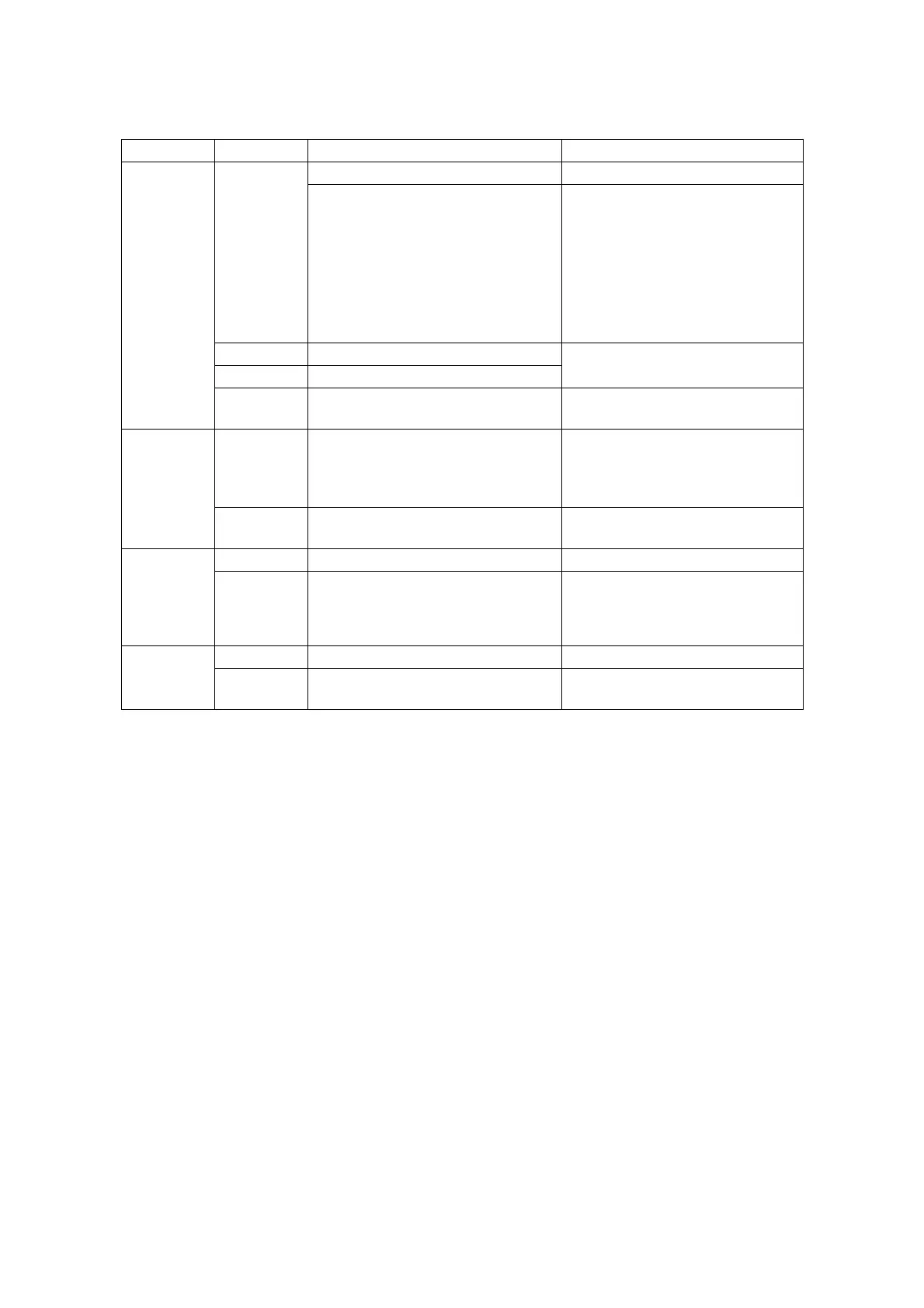

Table 4 Periodic inspection table

Frequency Item

Details Measures

Amount Refill the oil. Oil

Color (Reddish brown, dark

blown, and cloudy white are not

good.)

This pump uses carbon in internal

member of framework.

Oil may become black when it

runs. However, there is not it in the

aberration.

Replace the oil.

Sound Abnormal sound

Vibration Abnormal vibration

Check nuts and bolts for

looseness. If not clear, contact us.

Once/3

days

Current

value

Difference from the rated value Check the cause of an overload.

If not clear, contact us.

Surface

temperature

Surface temperature

(The temperature higher than the

room temperature by 45℃ or more

is abnormal.)

Check the cause of an overload.

If not clear, contact us.

Once/week

Oil leakage Oil leakage from the shaft seal

section and plugs.

Replace seals, or contact us.

Inlet filter Clogged with dust Clean the inlet filter. Once/3,000

operation

hours or

once/6

months

Oil Even if no problem is recognized,

be sure to replace the oil.

Replace the oil.

Coupling Damage or fracture Replace the coupling. Once/year

Oil pump

filter

Clogged with dust Clean the oil pump filter.

2) Inspection of the amount of pump oil

Refill the pump oil so that the pump oil level is kept within the range of the red lines

showing the upper and lower limits on the oil level gauge during operation.

3) Inspection of oil leakage

When oil leaks from the shaft seal section or drain plug seal section, repair is required. Our

specified O-rings and seals are always available from the service departments shown at the

back of this manual. When necessary, contact them.

4) Inspection of inlet filter

If the inlet filter is clogged with dust included in the evacuated gas, the pump’s efficiency

may deteriorate.

5) Inspection of abnormal sounds and vibration

Check the nuts and bolts for looseness.

Loading...

Loading...