8

1.8 - BOILER ANTIFREEZE PROTECTION

ANTIFROST PROTECTION

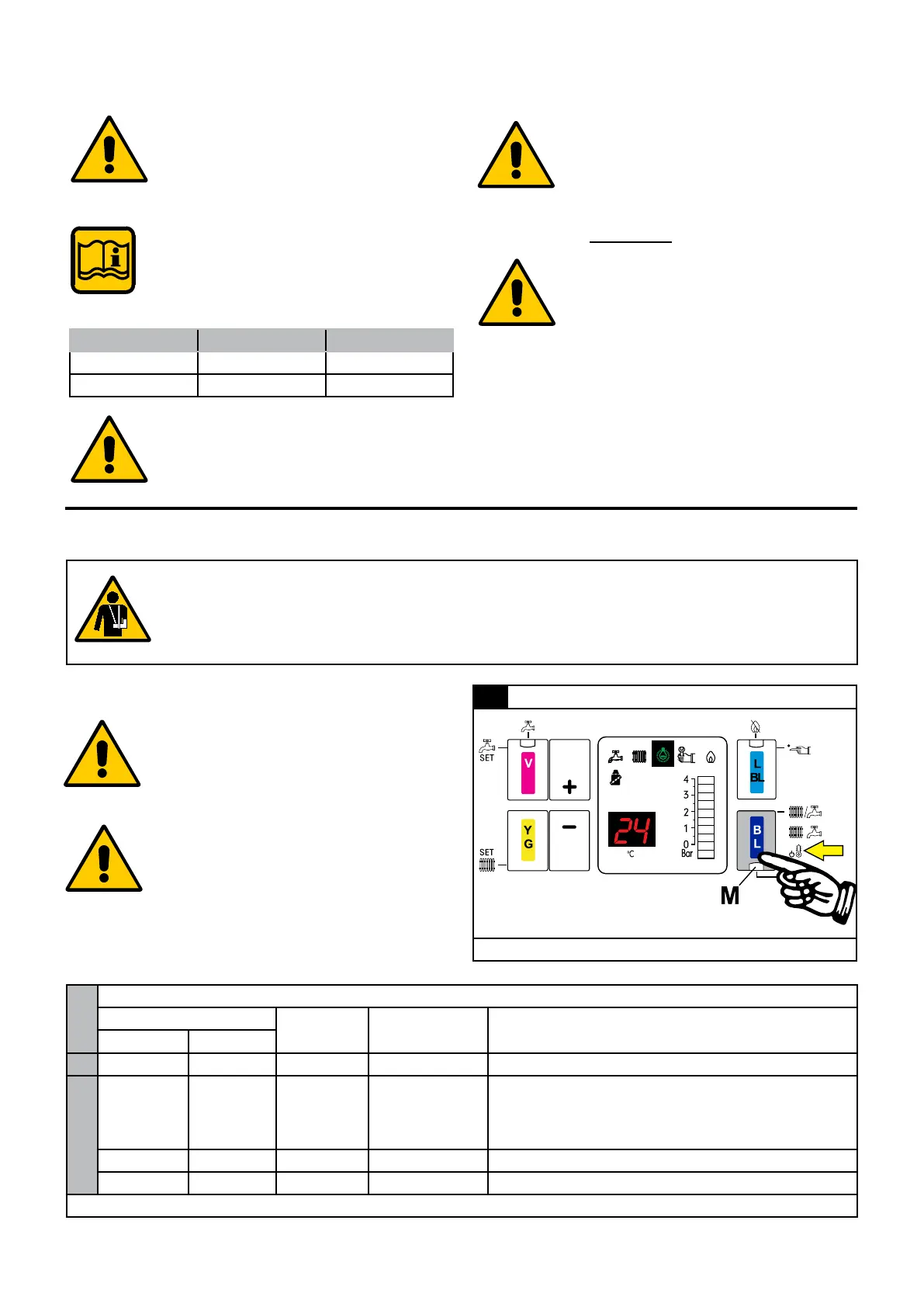

Press ‘‘BLUE’’ button, up to led M OFF.

1.7 - WATER TREATMENT

The treatment of the supply water allows to

prevent inconveniences and maintain the

over time.

The ideal water pH in heating systems must

To minimise corrosion, it is crucial to use

properly, the metal surfaces must be clean.

(see system protection ACCESSORIES sect.

in domestic price list)

ATTENTION (*) see general warnings 1.1

The heating only models are NOT suitable for

the production of water for human consumption according

ATTENTION!

ANY DAMAGE TO THE BOILER CAUSED BY

THE FORMATION OF FOULING OR BY COR-

ROSIVE WATER WILL NOT BE COVERED BY

THE WARRANTY.

VALUE MIN MAX

PH 6,5 8

Hardness [°fr] 9 15

This protection can intervene only if the

electricity and gas supplies are connected.

If one of the two is not available and upon reset

11 (SR) a temperature between 2 ÷ 5°C is

detected, the appliance will behave as described

in tab. pos 2.

The heating system can be protected eectively

from frost by using antifreeze products with

inhibitor for heating systems (specific for

multidmetal)

Do not use car engine antifreeze products as

they could damage the water gaskets.

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

Outdoor installations, must be done in partially protected places and must be use additio-

nal heater kit (optional) antifrost for siphon (condensate drain)

Declared ambient temperature, with use of the heater kit = -15 ° C.

P

O

S

ANTIFREEZE FUNCTION

Power supplies 11 - SR (*)

Status

antifreeze function

Actions

Electric Gas

1 ON ON < 7 °C ON - Burner and Pump ON until T > 15°C

2

ON OFF

< 5 ÷ 5 °C ON

FAULT SIGNAL CODE Fr (E16)

(with Electrical power supply ON)

(see par. 4.6 - ERROR CODES).

Ignition inhibited.

OFF ON OFF Ignition inhibited.

OFF OFF OFF Ignition inhibited.

(*) Flow sensor

Loading...

Loading...