Bulletin 30-020.007

Copyright © 2019 Unico Inc. Page 22

By measuring and totaling the airflow of all outlets, the

total airflow of the system can be closely approximated

and provide a crosscheck for the airflow determined

from the motor amperage using the airflow-amperage

table that is shipped with the Blower module. Use

Table 9 to correct the airflow.

Note: These tables are for the specific motor

installed in each blower module. Be sure the

table used applies to the correct model number

that is shown on the table.

Check Static Pressure Airflow should be verified

using the amps listed on the yellow label on the ST2

blower and from the control board for the EC blower.

If the air flow is low, it is because of a restriction.

Check static pressure to find the restriction and correct.

Measure the external static pressure (see the following

section) in the supply plenum at least two feet (610

mm) from the unit and verify that it is within the

allowable range.

It is not necessary to measure the return duct static

pressure unless it was field fabricated. The maximum

return static pressure (including filters) should be 0.15

inches of water (37 Pa). If it is greater than 0.15 inches

of water column, subtract the extra return system

pressure drop from the supply plenum static pressure

to get the total static pressure drop.

For example: If the supply static pressure is measured

to be 1.6 inches w.c. and the return system pressure

drop is 0.25 inches w.c, the total static pressure drop as

shown on the blower curve is: 1.6 - 0.10 = 1.50. In this

case the static pressure is too high.

If the restrictor plate (standard units only) is not

positioned according to Table 4, the static pressure

reading is not an effective indicator of airflow although

it should still be recorded. In this case, measuring

motor amperage is the only reliable indicator.

Check Outlet Airflow. Measure and record the air

flow from each outlet with a TurboMeter (refer to Tech

Note 113, How to Measure Outlet Airflow, for more

information). Place the TurboMeter against each

outlet, centered as best possible and record the “knots”.

Multiply the knots by 2 to obtain CFM, then sum all

the outlets. The sum is the total airflow; this can be

compared to the outlet indicated by the amperage. A

significant difference could indicate duct leakage.

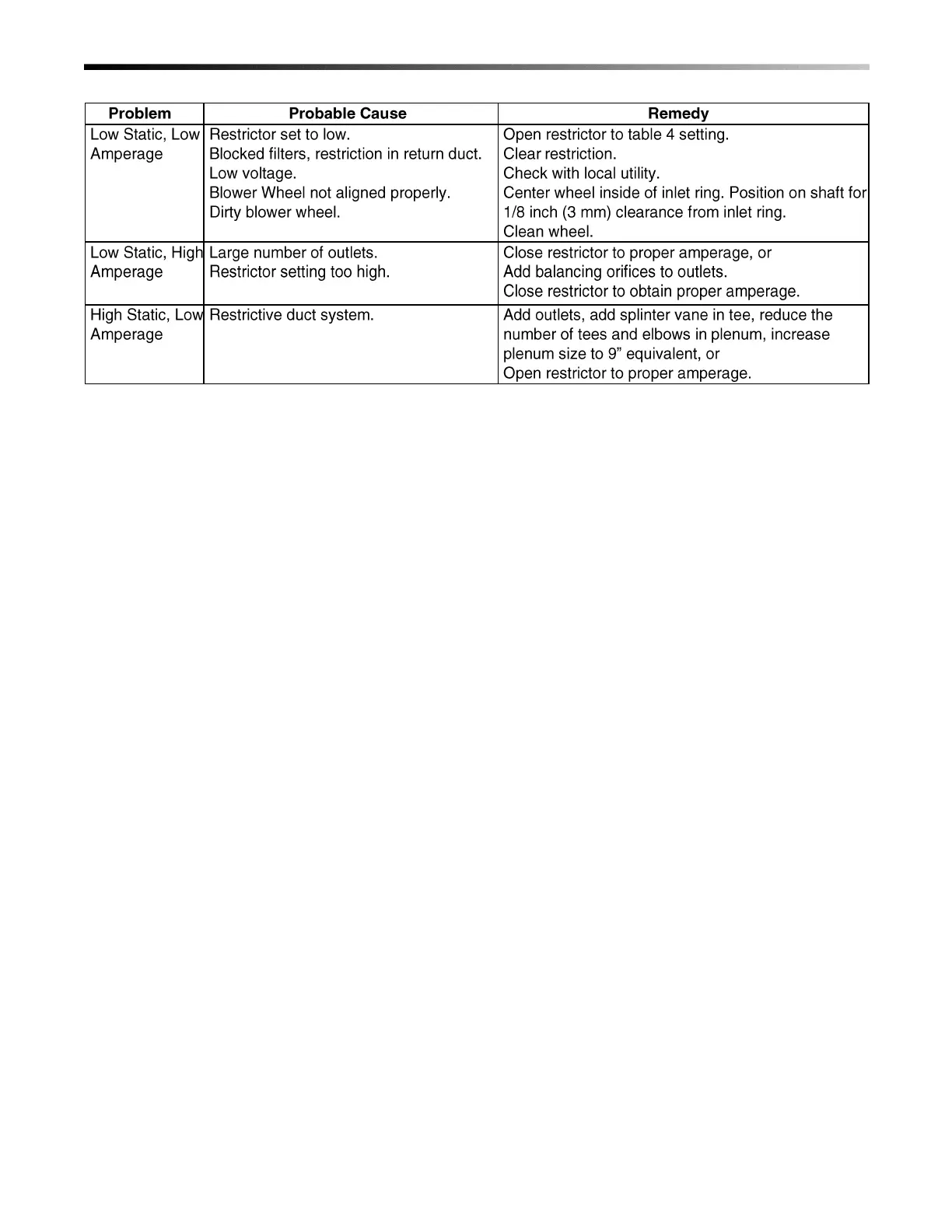

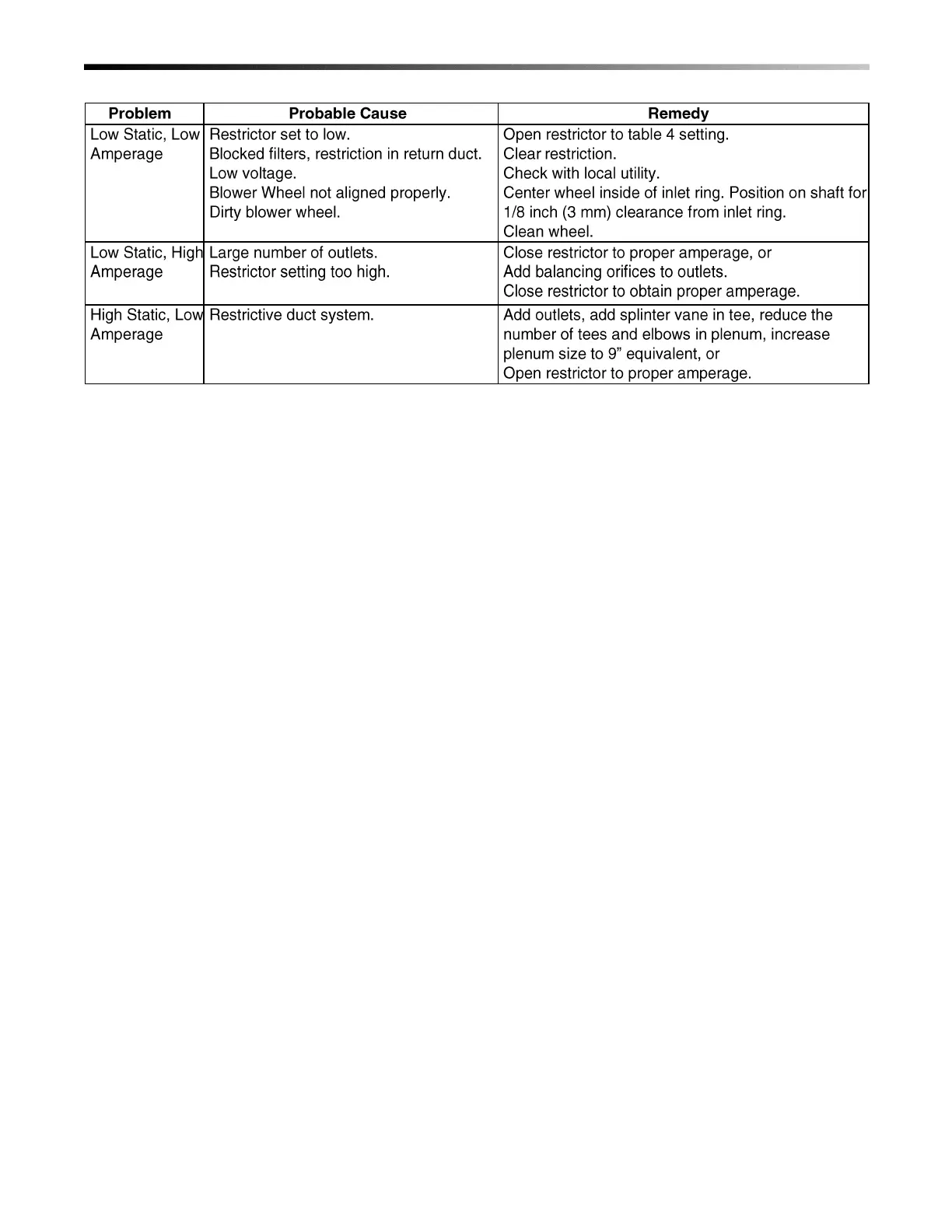

Table 10. Airflow Troubleshooting Chart

How to Measure Static Pressure. Measure the supply

plenum static pressure at least 18-inches (457mm)

from the unit, but before any tee or elbow. A distance

of between 2 and 3-feet (0.6 to 0.9m) is best. Use an

inclined manometer capable of reading at least 2.5

inches of water column (622 Pa), such as Dwyer

Instrument’s model 109 manometer. Be sure to zero the

scale and level the manometer.

A magnehelic gauge that measures up to at least 2.5

inches of water may also be used.

Use a metal tube, typically ¼-inch (6mm) diameter, to

measure the static pressure. Determine where you want

it and cut or punch a small hole in the duct. Make the

hole the same size as the metal tube to prevent leakage.

Insert the metal tube 1-inch (25mm) so that the tip of

the tube is flush to inside wall of the duct and

perpendicular to the air stream as shown in Fig. 32.

Attach the metal tube to the manometer using a rubber

hose (usually supplied with the manometer). Record

the pressure.

Note: If the tube is not perpendicular to the air stream,

the reading will be in error. You will get a higher

reading if the tube is angled toward the air stream.

Loading...

Loading...