Bulletin 30-020.007

Copyright © 2019 Unico Inc. Page 21

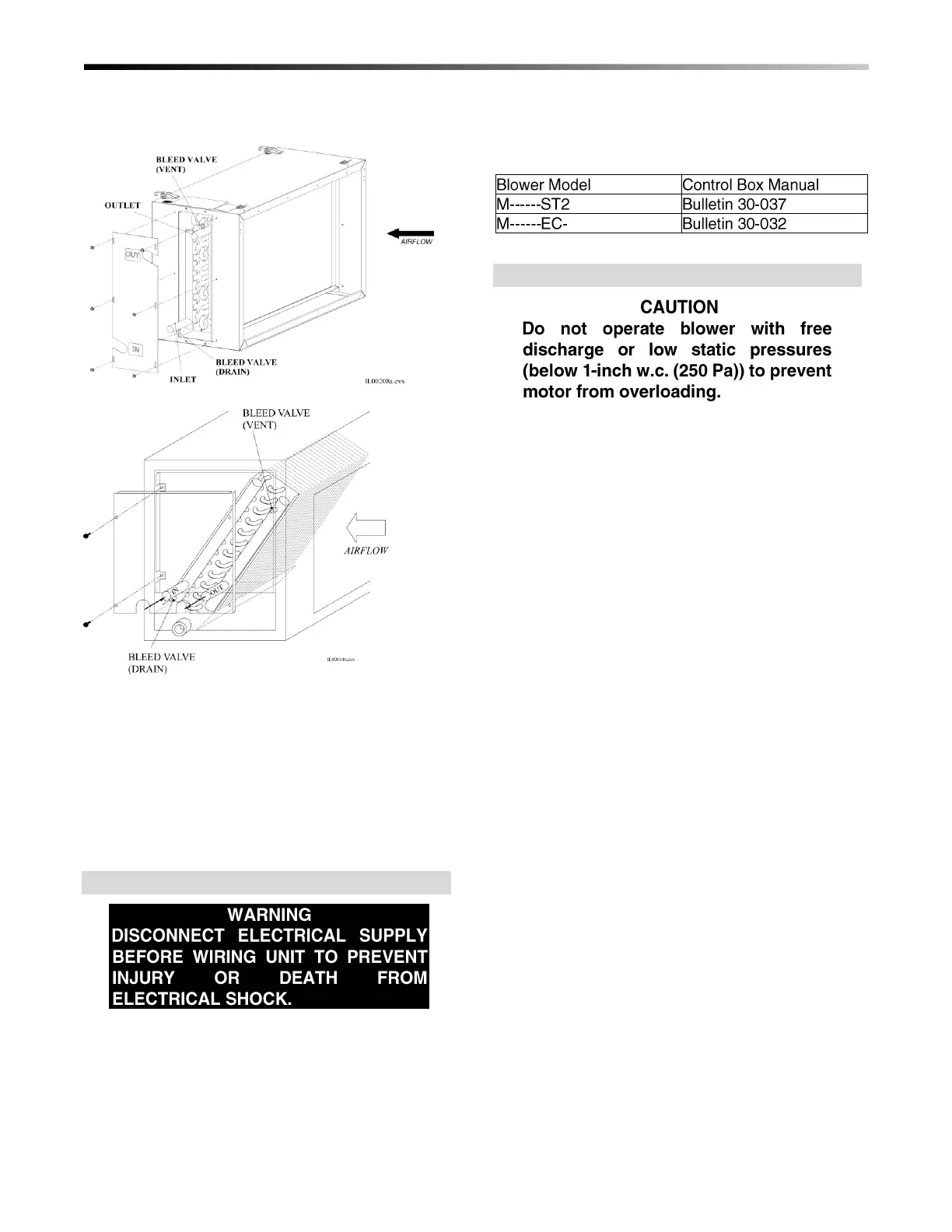

After venting the chilled water coil, replace the access

panel and seal around the connections with the rubber

gasket provided.

Figure 31. Water Coil Connections Coil Cleaning.

The coil should be sprayed with liquid detergent, or

any commercially available evaporator cleaner

solution, thoroughly and rinsed thoroughly before

installation to assure proper drainage of condensate

from the coil. This will eliminate moisture carry-over

and assure maximum coil performance. As an alternate

to cleaning, allow approximately 50 hours of break-in

time to achieve the same results.

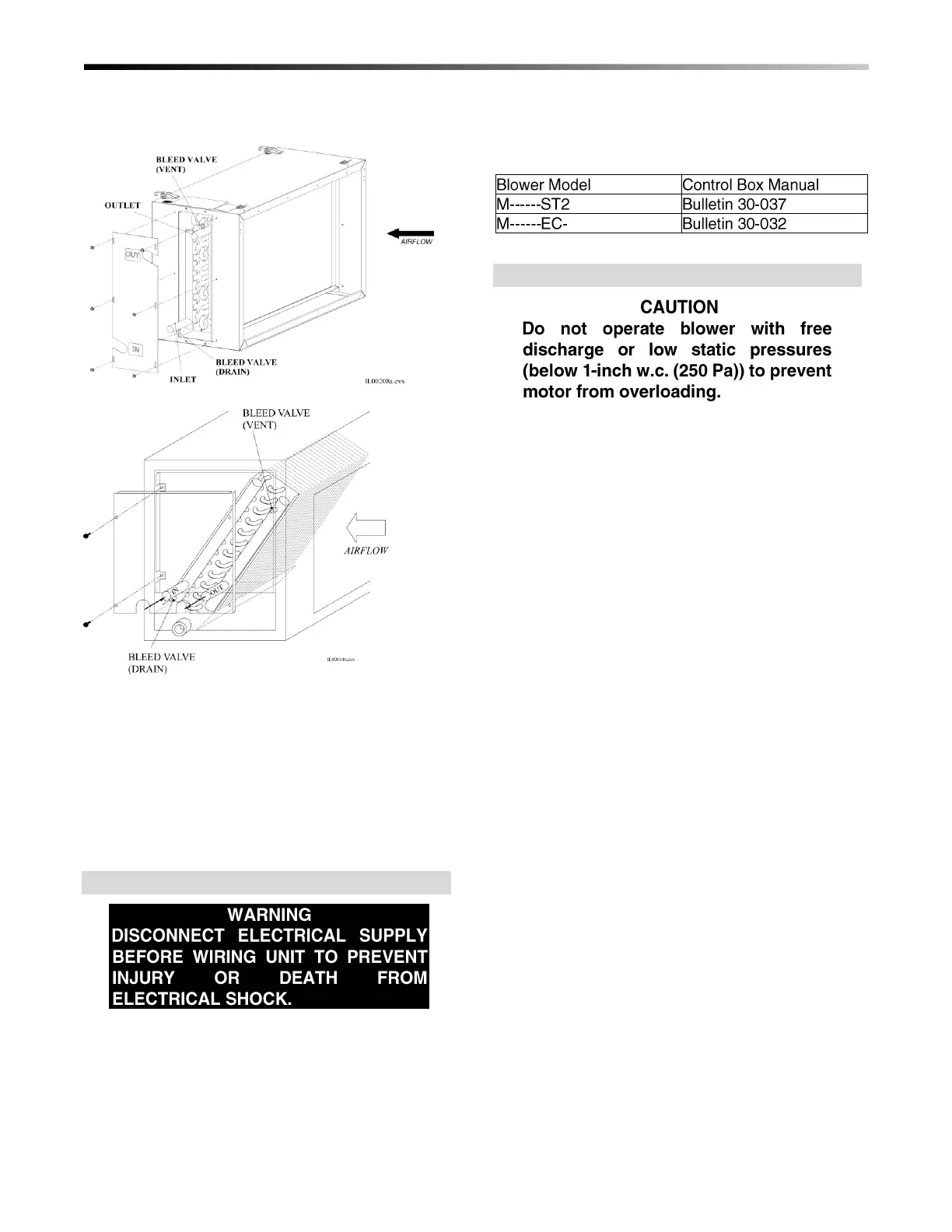

WIRING

All electrical wiring must comply with local codes and

ordinances. Blower module controls and components

are bonded for grounding to meet safety standards UL

Standard 1995 and CAN/CSA-C22.2 No. 236 and are

listed by ETL. All 50 Hz units are CE marked and

conform to the Low Voltage 73/23/EEC and EMC

89/336/EEC Directives.

The control wiring, sequence of operation, and

troubleshooting are included in a separate bulletin for

each control box.

Table 9. Control Box Manuals

CHECKING AIR FLOW

After the system is installed and before charging

system, check for proper airflow. Record the position

of the restrictor plate, the plenum static pressure, and

the motor amperage (standard units only). With this

information, the amount of airflow can be determined.

As a recommended further check on airflow, use a

velometer to measure the airflow from each outlet.

The most convenient instrument to use is a hand held

vane type velocity meter that fits directly over the

outlet. The Turbo-Meter (Davis Instruments Catalog

No. DS105I07) or equivalent meter will give a direct

LED readout on the Knots (FPM x 100) setting, when

multiplied by 2 gives the CFM of the outlet within an

accuracy of 10%. (Multiply ‘knots’ by 0.94 to obtain

L/s.) Refer to Technote 113 for more information.

Loading...

Loading...