4

/10

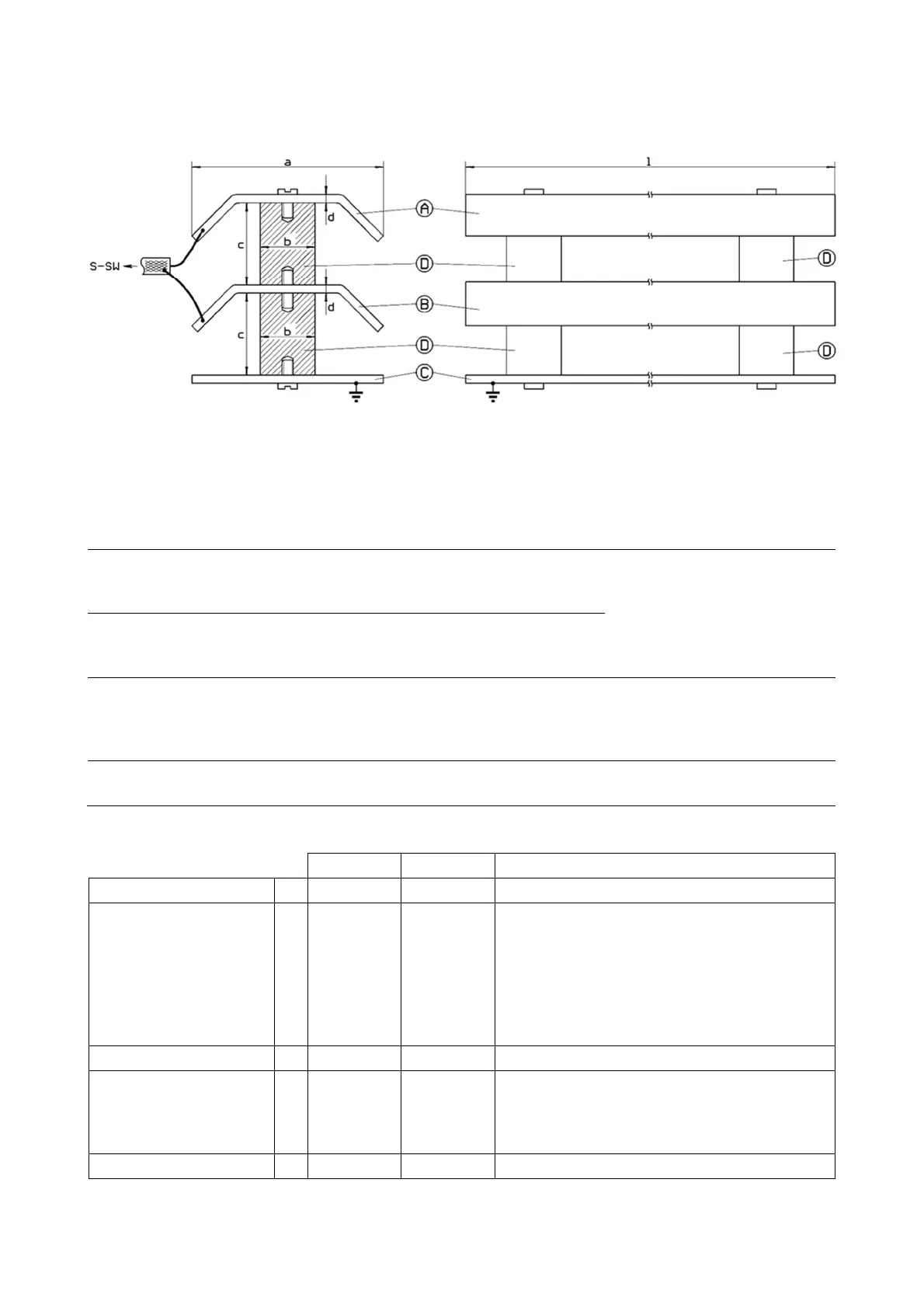

The connection to the sensor electrodes is made by the 2-pole connector X3 and a coaxial cable.

According to the drawing (see Figure 1), the core is connected to the left terminal X3/1 (measuring

electrode) and the shield to the right terminal X3/2 (opposite electrode).

2.2 Sensor Electrodes

Figure 2

The sensor electrodes can have any geometric shape. It is only important that the two elec-

trodes have approximately the same area and are fixed to a grounded structure.

electrode

The measurement electrode is connected

to X3

/1 of the evaluation unit via the core

conductor of the coaxial cable.

material (sheet steel, alu-

minum, etc.). They should

have the same design.

The opp

osite electrode is connected to

X3/

2 of the evaluation unit via the shield of

the coaxial cable.

The design of the mounting structure depends on the conditions at the

installation place. It must be made of conductive material (metal, for fur-

ther examples see above).

The mounting structure must be connected to the earth potential!

The spacers must be made of electrically isolating material (plastic / ce-

ramic, see table below).

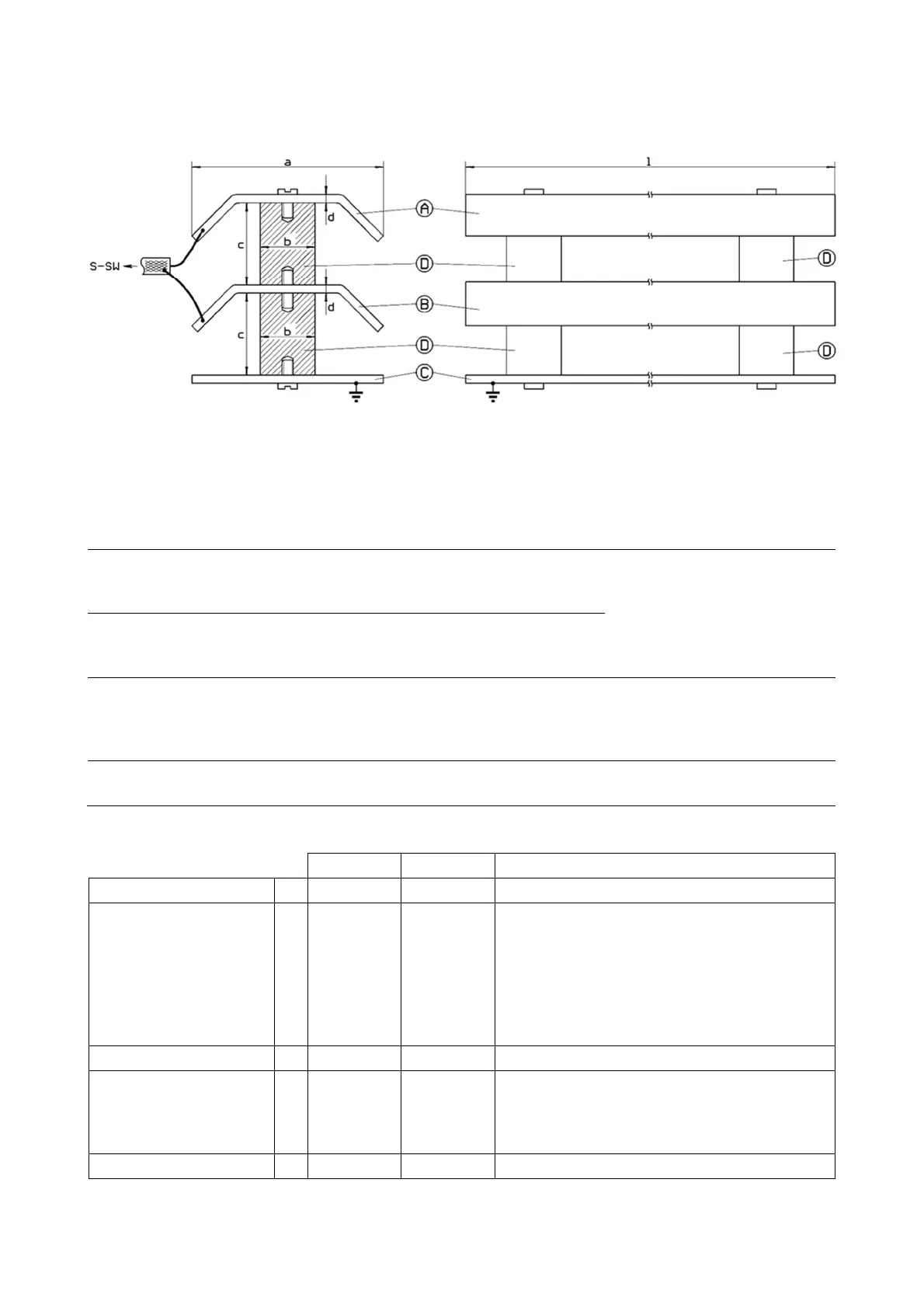

Construction Rules

a 10 mm 200 mm

b no specifi-

cation

no specifi-

cation

Electrically isolating material (plastic / ce-

ramic).

The selected diameter must ensure suffi-

cient mechanical stability.

Spacers are available as accessories from

UNICONTROL (UC spacer M4, M6, M10

and M12.

c 5 mm 80 mm

Capacity

d no specifi-

cation

no specifi-

cation

The material mechanical capacity is not crit-

ical. It should be chosen

the electrodes have enough mechanical sta-

bility.

l 20 mm 4000 mm

The sensor electrodes can have any geometric shape. It is important that the two electrodes

have approximately the same areas.

Loading...

Loading...