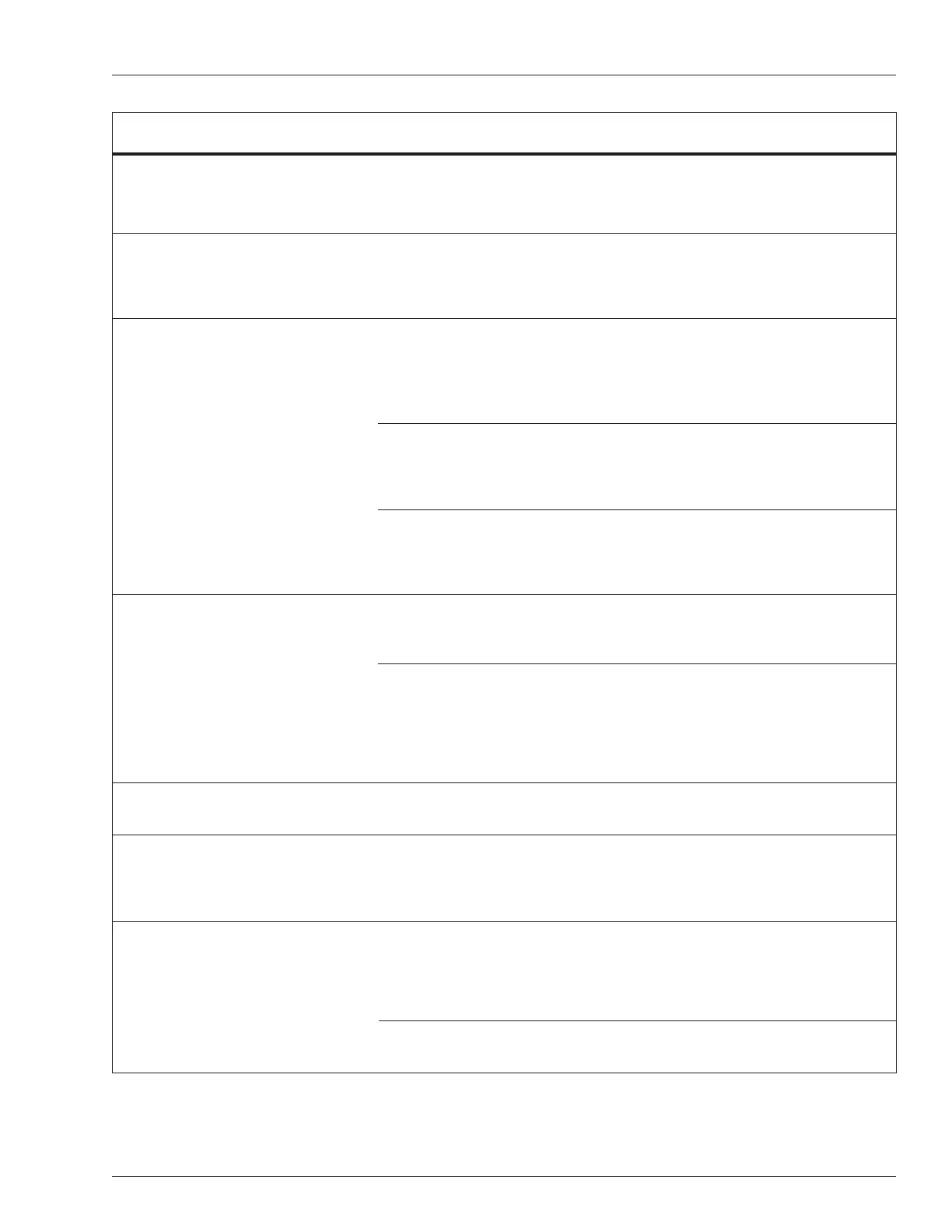

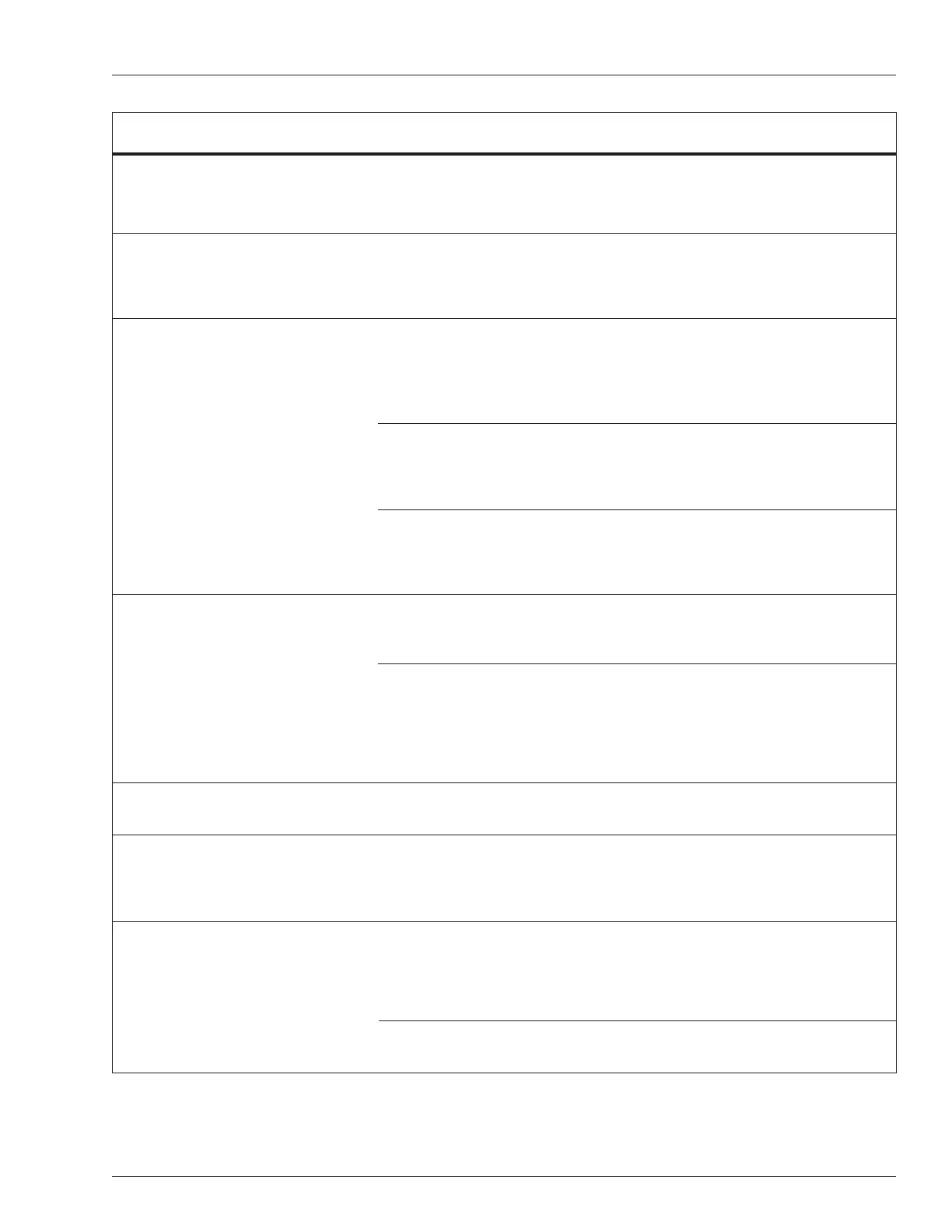

Chapter 11 – Troubleshooting

SB85J Fixed Axle – 0112975 57

Symptom

Engine starts from the upper con-

trols but no boom functions

work – machines with AC gen-

erator option only.

Engine dies when the control se-

lector switch at the lower con-

trols is placed in the upper

conttrol position.

Constant tone alarm sounds

while the engine is running.

Constant tone alarm sounds and

engine shuts off.

Horn is sounding intermittently

and the overload light is flashing.

Horn is sounding constantly and

the overload light is on.

Platform overload sense system

does not work while operating

the upper controls.

Possible Cause

The machine/generator switch is in

the generator position.

Upper controls are not set-up properly.

High engine temperature.

Low oil pressure.

No alternator current/broken fan belt.

High engine temperature.

Low oil pressure.

The load in the platform is greater

than the rated capacity.

The platform overload system is in

error mode.

Drive/boom selector switch is in the

drive position and the main boom is

below horizontal.

System needs calibration.

Corrective Action

Place the switch in the machine po-

sition to operate machine functions.

At the upper controls, pull the emer-

gency stop button upward and turn

the anti-restart master switch on.

Lower the platform and reduce the

engine speed to idle for five minutes.

Turn the engine off and let it cool. Do

not restart the engine until the cause

of overheating has been corrected.

Lower the platform and turn the en-

gine off. Do not restart the engine until

the cause of low oil pressure has been

corrected.

Turn the engine off. Do not restart the

engine until the cause of no alterna-

tor current has been corrected or the

fan belt is replaced.

Let the engine cool. Do not restart

the engine until the cause of overheat-

ing has been corrected.

Do not restart the engine until the

cause of low oil pressure has been

corrected. The engine can be re-

started with low oil pressure, but it

will only run a few seconds before it

shuts off again.

Remove load from the platform until

the alarms stop.

Remove load until at or below rated

capacity. Cycle machine power off,

then on. If alarm continues, system

may need recalibration.

Normal operation. The platform over-

load system is inactive while driving

with the booms in the stowed posi-

tion to prevent accidental activation

due to rough terrain.

Refer the problem to a qualified ser-

vice technician.

Loading...

Loading...