Service and Repair

3-7

0.6 LUBRICATION

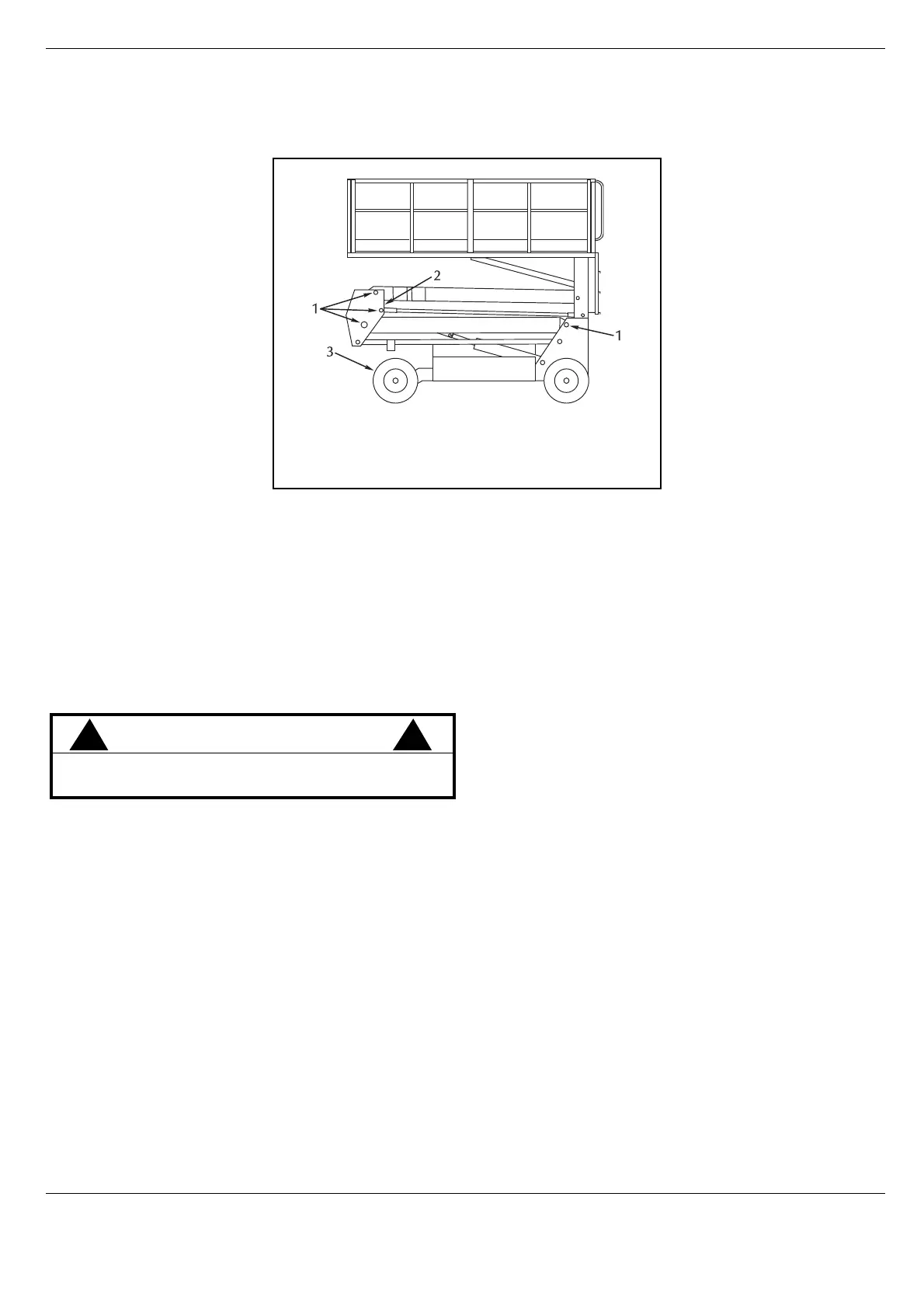

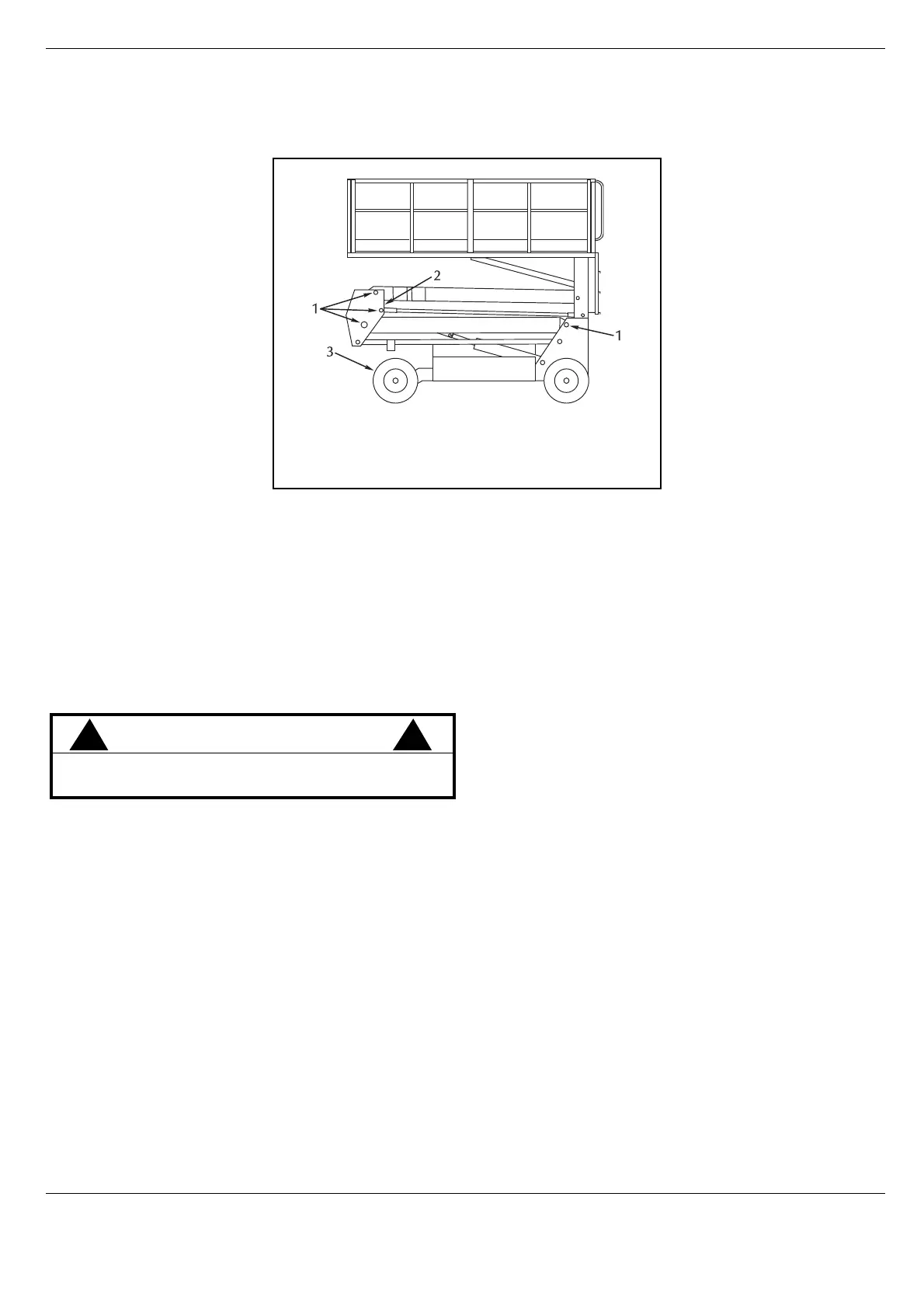

Refer to Table 3-1 for lubrication intervals and Figure 0-2 for location of items that require lubrication service.

Refer to the appropriate sections for lubrication information on the hydraulic tank and filter.

Figure 0-2: Lubrication Points

Grease Fittings

Wipe each grease fitting before and after greasing. Using multipurpose grease in a grease gun, pump the

grease into the fitting until grease just begins to appear at the edges of the pivot, wipe off any excess grease.

Linkage Gears

1. Raise platform fully.

2. Using another work platform or ladder, get up high enough to comfortably reach gears.

3. Use a long handled brush to apply multipurpose grease to the face of the gears.

4. Lower the platform after greasing.

Steering Linkage

Apply one or two drops of motor oil to each pivot and king pin bearing.

Hydraulic Pump

Remove the capscrews that mount the pump to the engine. Remove the pump from the engine and apply high

pressure molybdenum grease to the splines. Re-install the pump and secure with the capscrews.

Hydraulic Oil Tank & Filter

(Figure 0-3)

Fluid Level

With the platform fully lowered, the oil should be visible in the sight gauge. If the oil is NOT visible, fill the tank

until the oil can be seen. DO NOT fill above the sight gauge or when the platform is elevated.

CAUTION

!!

Do not use hands to apply grease or allow any

body part to enter the elevating assembly.

1. Grease Fittings

2. Linkage Gears

3. Steering Linkage

Loading...

Loading...