5

4 SAFETY AND ACCIDENT PREVENTION INFORMATION

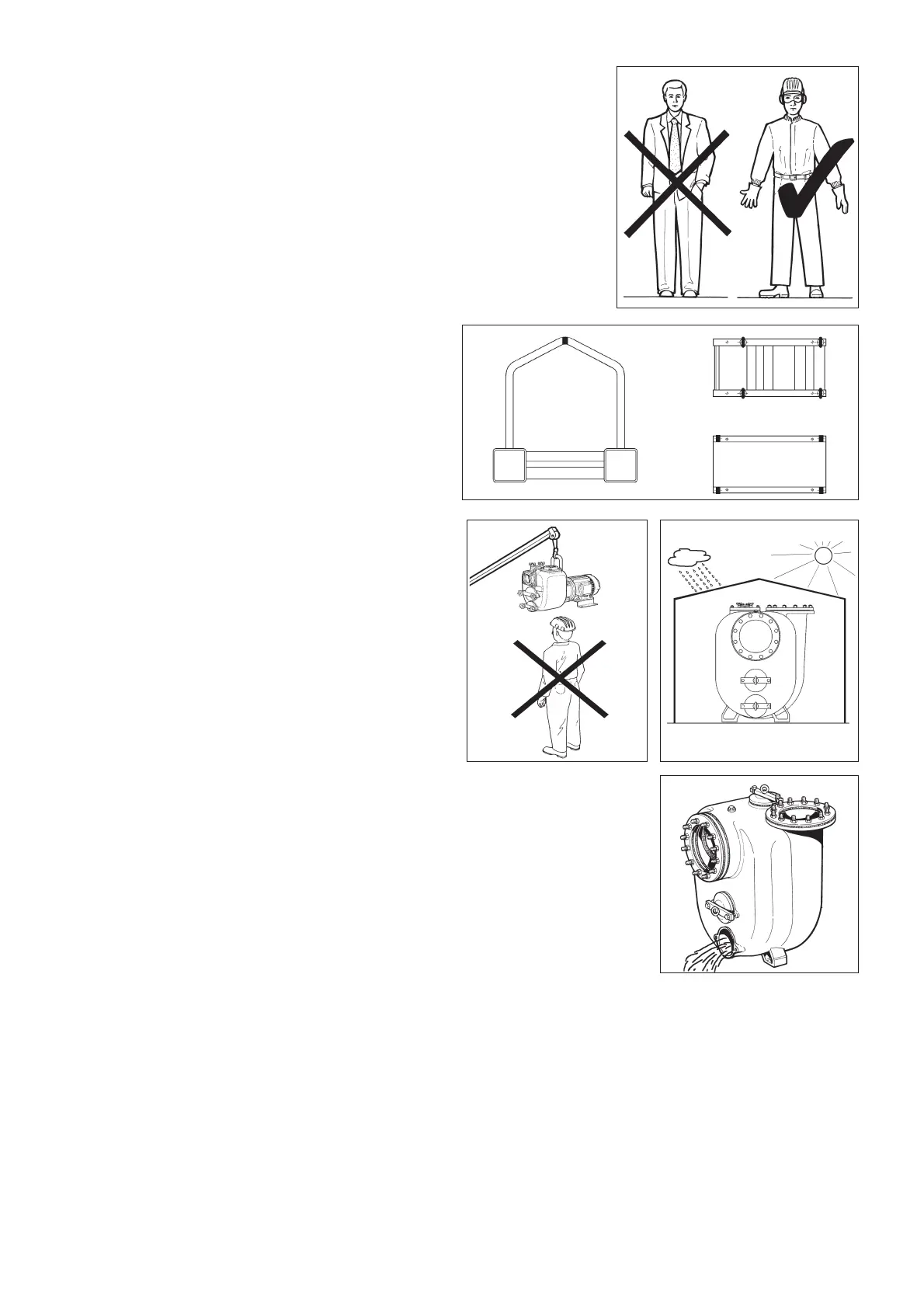

When working near the pump, dress appropriately, avoiding clothes with loose items (ties,

scarves, etc.) which could get caught in moving parts. Use overalls made according to

safety regulations, gloves, insulating shoes, safety glasses, ear plugs and helmet (fig.1).

Do not carry out maintenance on the engine while it is running.

Keep hands away from moving parts (e.g. belts, couplings, etc.).

Keep hands away from hot areas of the engines (fig. 4).

Do not mount on the pump to carry out maintenance operations of any kind.

5 IN CASE OF EMERGENCY

Turn off the electrical supply (for electrically driven pumps).

Shut off the engine (for engine driven pumps).

Notify the person responsible for running the plant immediately.

6 HANDLING AND TRANSPORT

6.1 Method of transport

The pump must be transported safely.

6.2 Installation

During installation and maintenance, all the components used

must be handled and transported securely by using suitable

slings. Handling must be carried out by specialised personnel to

avoid damage to the pump and to persons. The lifting rings

attached to various components should be used exclusively to

lift the components for which they have been supplied. Figure

(1) highlights in black the lifting points of some typical base

plates.

Maximum lifting speed: Vmax

≤≤

0,5 m/s

Do not stand or pass under the pump while it is being

hoisted!(fig.3)

7 STORAGE

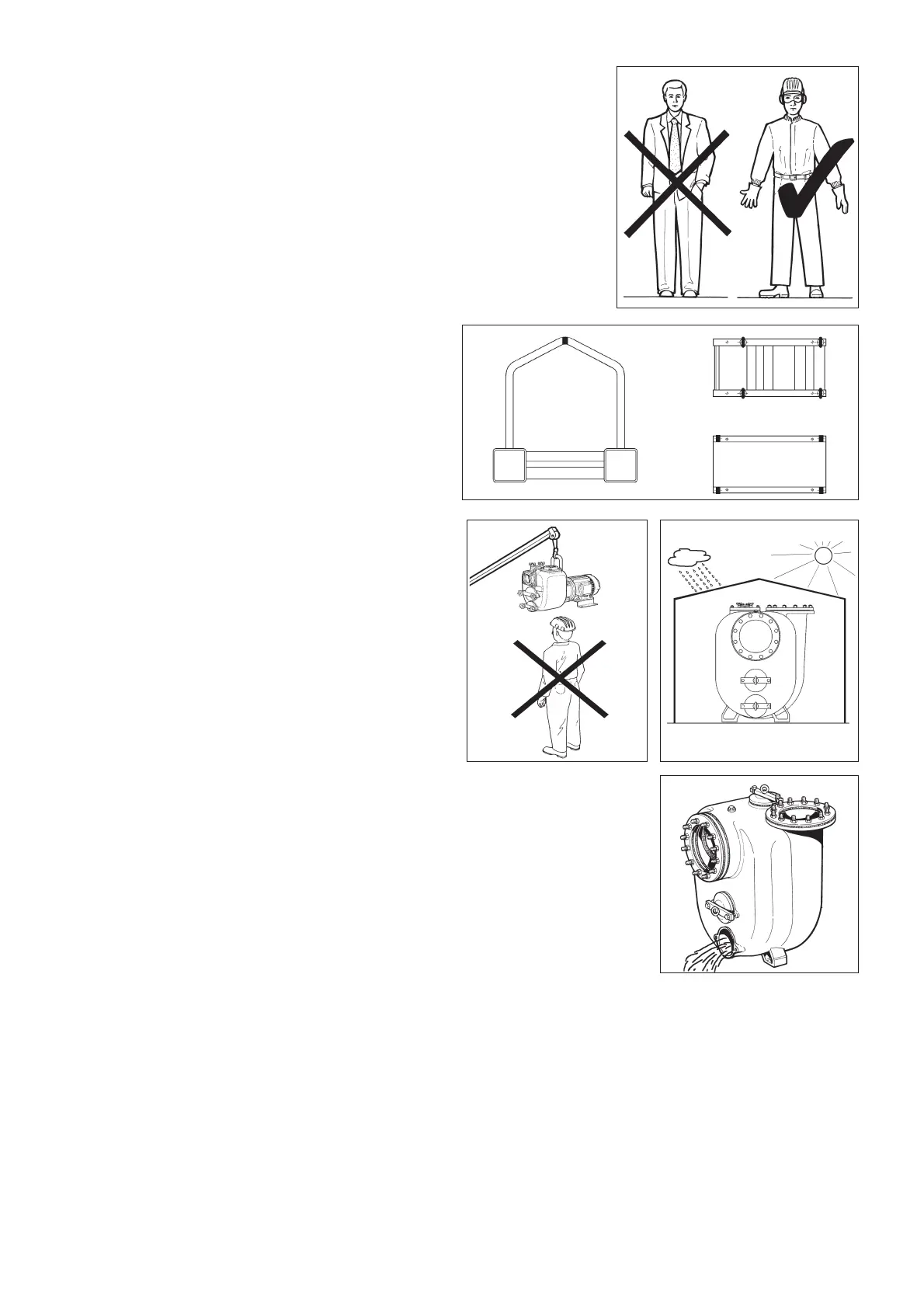

Store the pump under cover wherever possible. If the pump

must be stored in the open, cover it with a tarpaulin and grease

the bearings to avoid rusting. (fig. 4).

Avoid the accumulation of moisture around the pump.

Drain the casing through the drain cover (fig. 5) and the rear

plug mounted on some models. During winter months and

cold weather, the liquid could freeze and damage the pump

casing. If the liquid is hazardous, take all necessary

precautions to avoid damage and injury before emptying

the pump casing. From time to time, turn the pump shaft to

avoid encrustation inside the pump

8 ASSEMBLY

If the pump is supplied with bare shaft (pedestal version) it must be coupled to an electric

motor or internal combustion engine, taking account of the following:

- the coupling must be correctly sized for the power to be transmitted

- the coupling must be correctly aligned (see paragraph 9)

- the coupling guard must comply with applicable safety standards

- the rated power of the motor or engine

- the power absorbed by the pump (see the motor name plate)

- the motor or engine speed (see the motor name plate)

- the pump speed

9 INSTALLATION

The base plates of electrically or engine driven pumps must be anchored to a levelled concrete slab in which the foundation bolts have

been buried following the diagram supplied with the unit or available on request. The slab must be robust to absorb any vibrations and

sufficiently rigid to maintain the alignment of the pump to the motor or engine.

For trailer mounted pumps, block the wheels using the two chocks supplied.

9.1 Assembly

While the base plate is being anchored to the slab, check the flatness by placing a spirit level on the delivery flange of the pump.

If adjustments are necessary, the face of the slab must be adapted to the base plate, never the base plate to the slab.

The pump casing must be suitably supported when the pump is coupled to a gear box for agricultural use.

fig. 2

fig.3

fig. 1

fig. 4

fig. 5

Loading...

Loading...