13.6 Replacing type TCW, TC8W cartridge seals (fig. 10, 13, 14, 15, 16)

- Empty the pump casing as described

in paragraph 8.

Attention: residual liquid may be

found inside the pump casing, head

and suction line; take all necessary

precautions if the liquid is hazardous

(inflammable, corrosive, poisonous,

infected, etc.)

- Unscrew the nuts (52) (fig. 10) and

remove the pump casing, taking

care not to damage the casing

gasket (43)

- Block the impeller (03) and remove

the self-locking impeller nut (33)

- Remove the impeller (03)

- Disconnect the flushing lines.

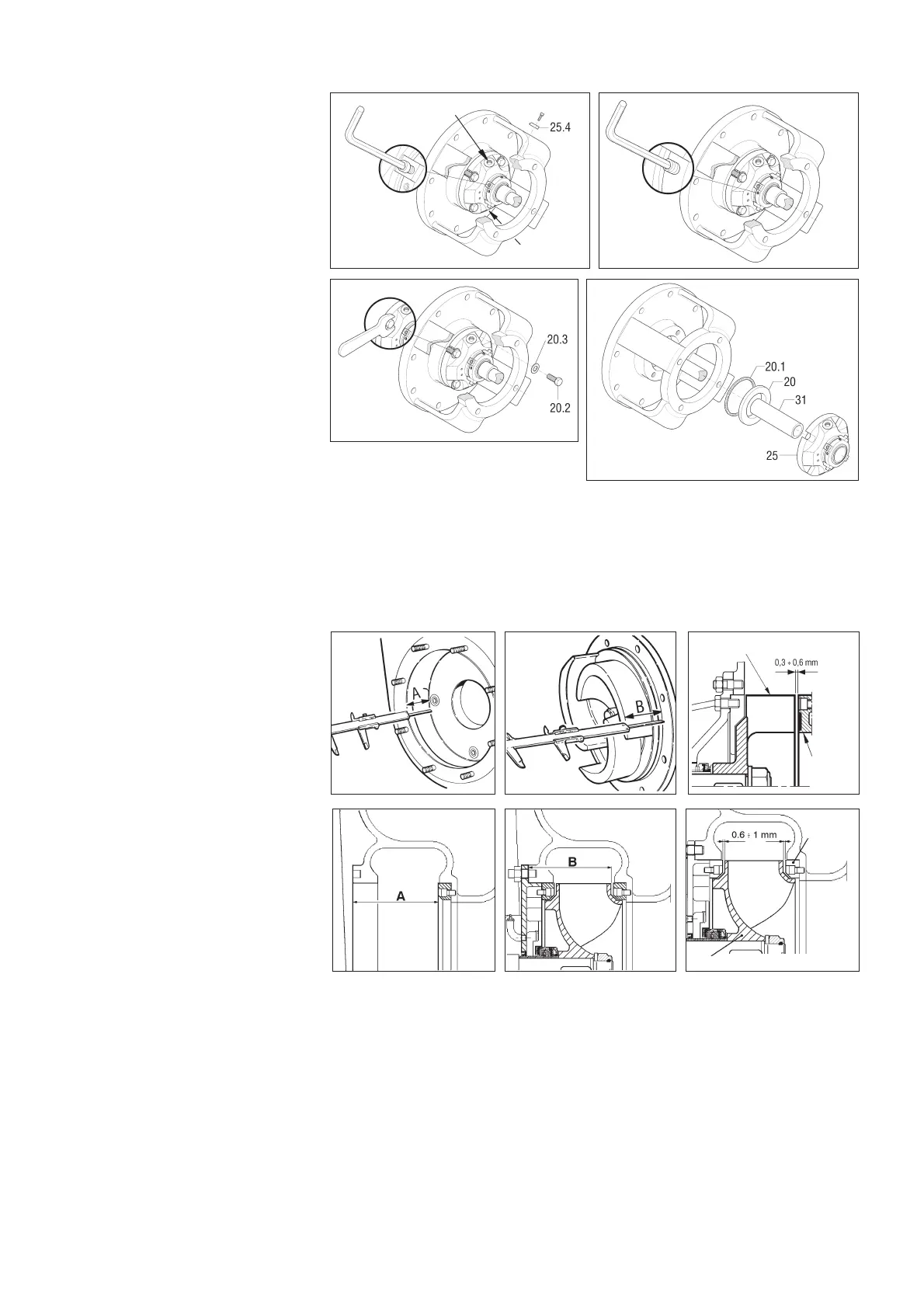

- Fix the seal lock setting plates (25.4)

in their seats (fig. 13)

- Loosen the grub screws of the shaft

sleeve (fig. 14)

- Unscrew the screws (20.2) which fix

the seal flange to the head (fig. 15)

- Remove the head (19)

- Remove the seal (25), the shaft

sleeve (31), the seal box (20) and the

gasket (20.1)

- If the gasket (20.1) is damaged, replace it

To assemble, proceed in reverse order

- To facilitate the initial assembly of the seal (fig. 18), smear a little oil on the shaft sleeve (31)

- Tighten the fixing screws (20.2) carefully (fig. 15) so as to avoid strain on the stationary seat of the seal

- Tighten the grub screws as far as they will go (fig. 14)

- Remove the setting plates (25.4) which hold the seal (fig. 13) and fix them in the appropriate holes in the flange so that they can be used

again to remove the seal

- Reconnect the flushing lines, begin flushing and bleed out air from the area around the seal. The seal must not run dry even for a few

moments.

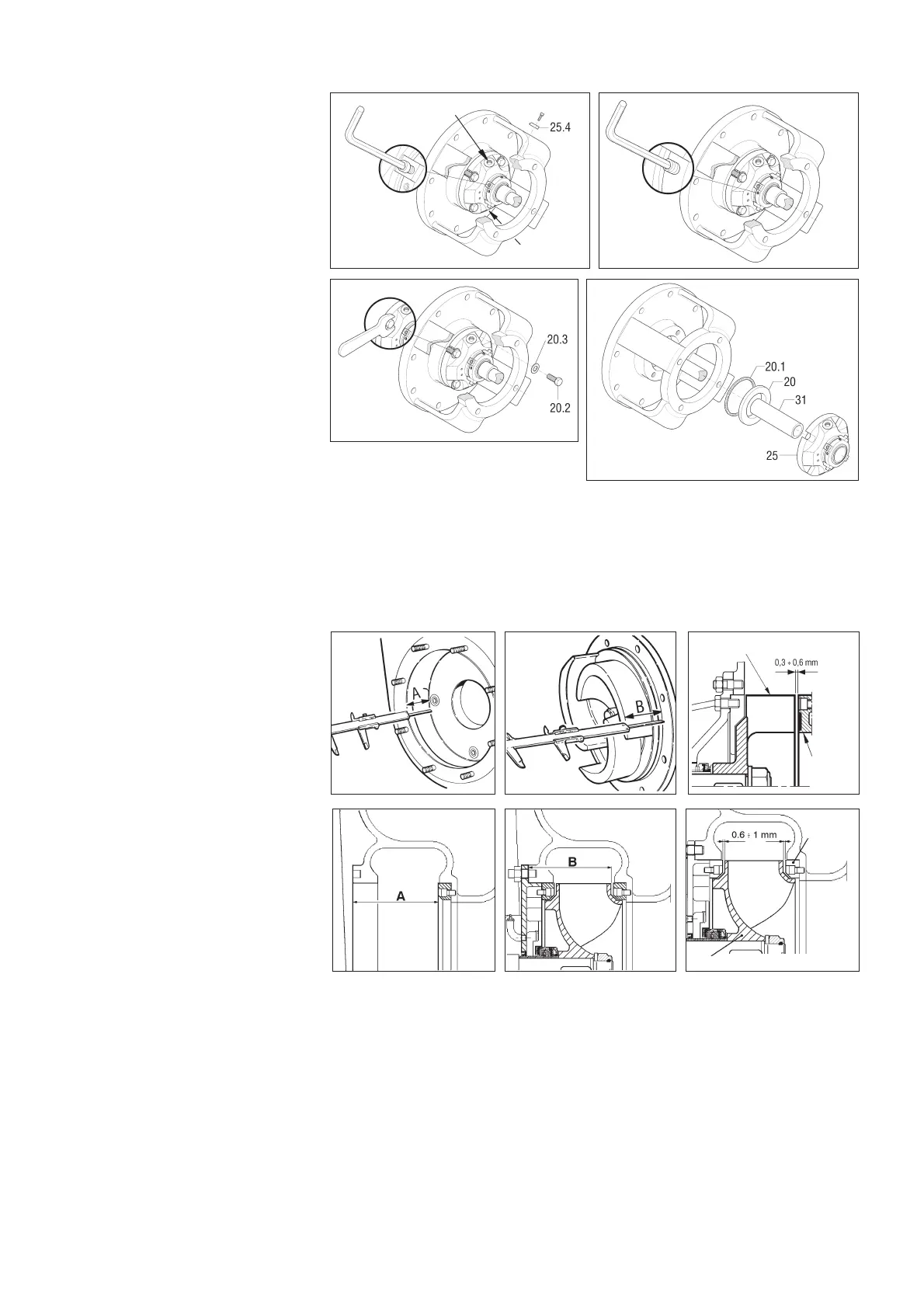

13.7 Positioning the impeller with reference to the wear plate(s)

- In all models, the distance between

the top of the impeller blades and the

surface of the wear plate must be

between 0.3 - 0.6 mm (fig. 19). For

the 12" model, the distance between

the impeller and the front and rear

wear plates must be between 0.6 - 1

mm (fig. 22).

To achieve this, dimensions A and B

in figs. 17, 18, 20, 21 must be as

nearly as possible equal. To this end,

use the shims (25.2) (fig. 11)

supplied with spare mechanical

seals. These shims are used to move

the impeller further forward if it is too

far from the front wear plate or too

near the rear wear plate. The shims

should be mounted between the seal

support ring (25.1) (fig. 11) and the

impeller. Further adjustments can be

carried out using casing gaskets (and

rear wear plate gaskets on models

which fit these). The presence of the

casing gasket (43) (fig. 10) 0.5 mm

thick then creates the correct

distance (fig. 19).

13.8 Maintenance of the bearings (fig. 10)

The pump is supplied with the bearings already greased and does not require maintenance for the first 500 hours of operation.

The bearings in the bearing housing must be lubricated appropriately, avoiding the use of too much grease which can cause overheating

and, as a result, damage to the bearings.

13.9 Replacing the bearings

Empty the pump casing

Remove the casing, the head and the mechanical seal

Remove the flexible coupling hub and the shaft key

Remove the outer bearing cover (08)

Extract the shaft from the coupling side

Extract the bearings using a bearing extractor

To reassemble, proceed in reverse order

fig. 14

flushing hole

flushing

hole

wear

plate

impeller

fig. 17

fig. 18

fig. 19

impeller

wear

plates

fig. 21

fig. 22

fig. 20

9

fig. 13

fig. 15

fig. 16

Loading...

Loading...