WARNING

In the event of a malfunction or abnormal operation, shut off the pump or pump unit

immediately to prevent a dangerous situation and/or damage (possibly severe) to the

pump or pump unit.

Inform to responsible persons. Determine the cause of the malfunction. Resolve the

problem before restarting the pump

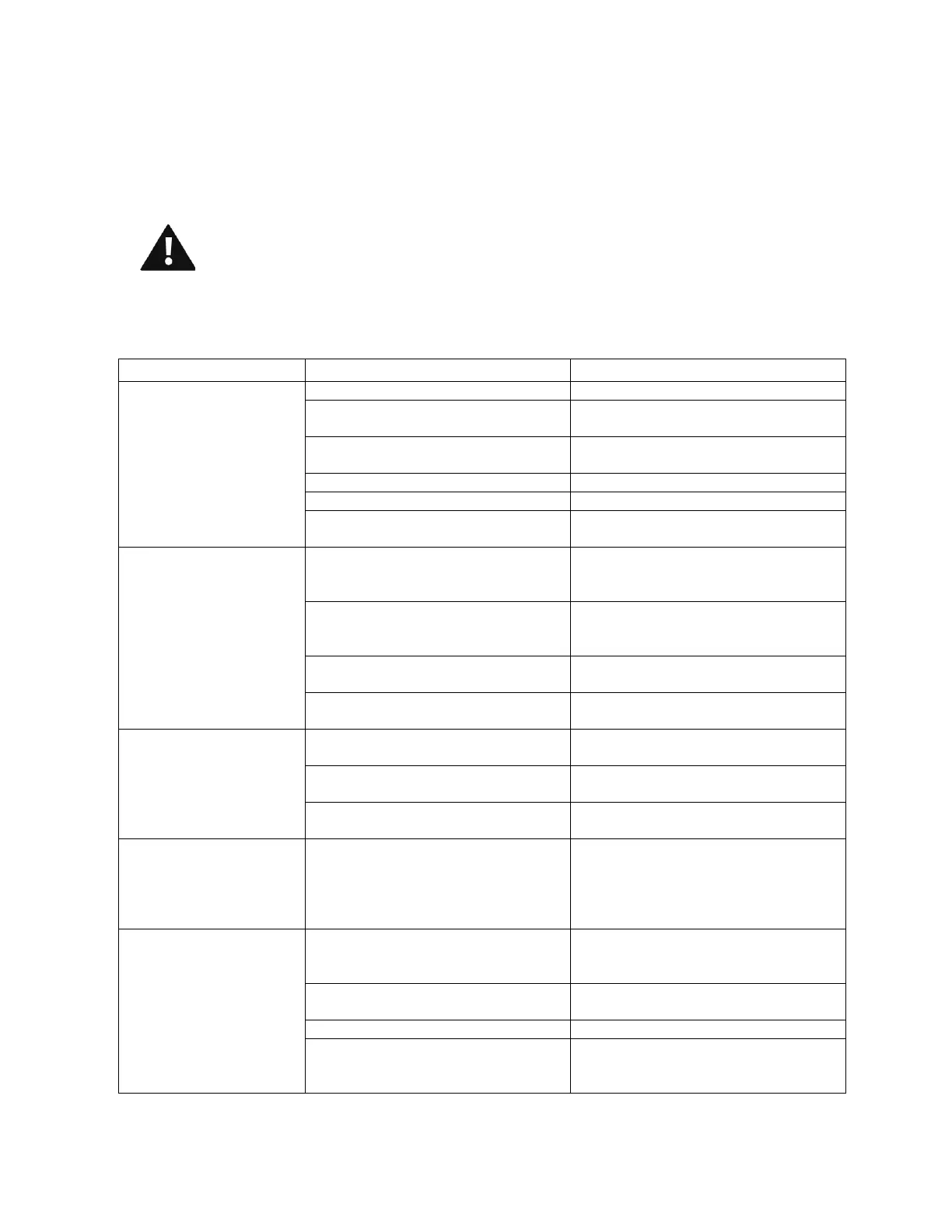

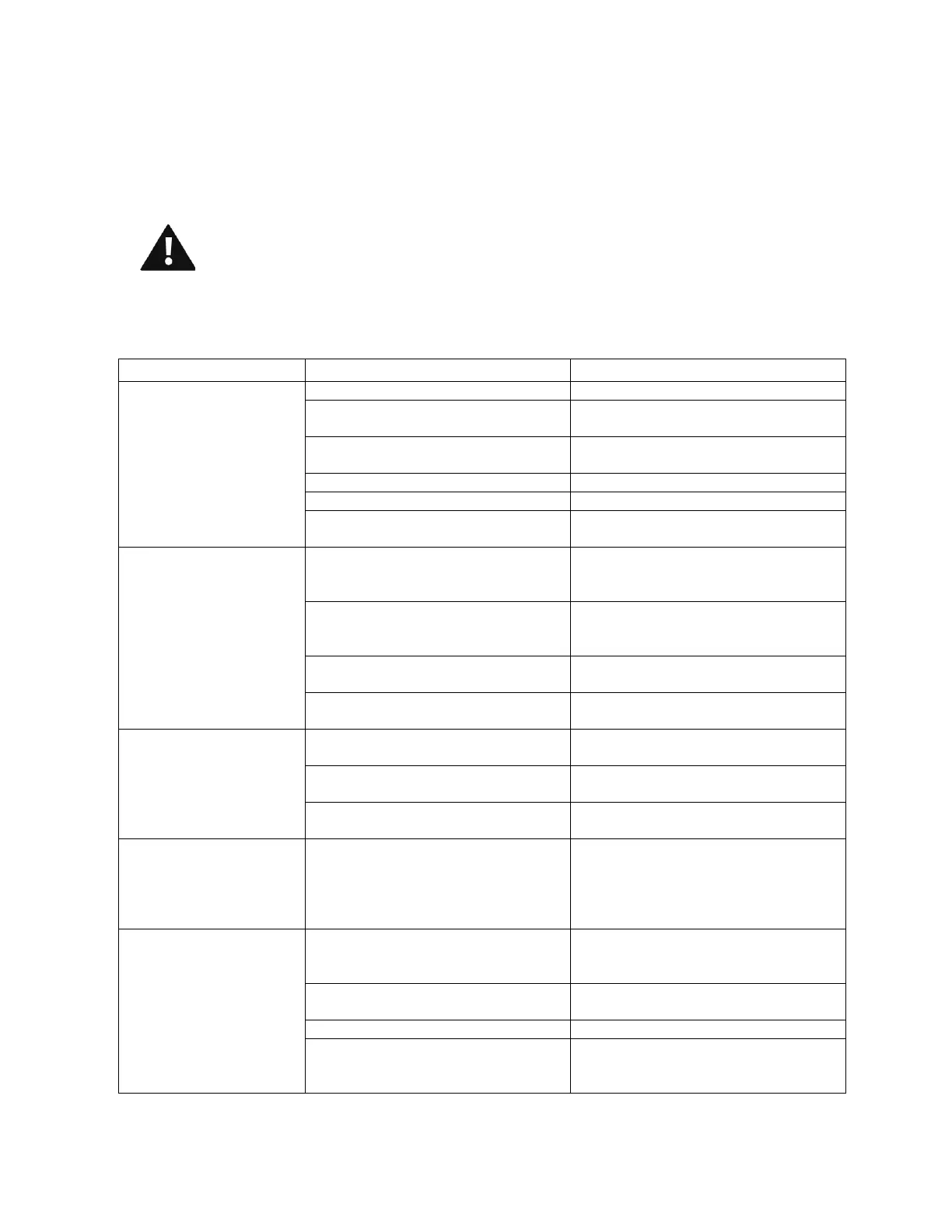

Verifications and solutions

Delivery pipe under pressure

Impeller may be worn or broken

Disassemble pump casing and check

impeller for wear

Suction strainer, where applicable,

may be clogged

Air entering through seal

Disassemble seal and clean it

Impeller clogged by foreign matter

Disassemble casing and remove

foreign matter

Pump does not deliver

liquid

Head required by the system is

greater than the rated head of the

pump

Revise system design or select a

different pump

Excessive flow resistance along

suction line

Revise distribution of elbows, valves,

constrictions etc.; where necessary,

increase diameter of pipework

Impeller clogged by foreign matter

Disassemble casing and remove

foreign matter

Suction/delivery pipes may be

obstructed or clogged

Locate the obstructed or clogged

area and clean

Pump does not deliver

enough liquid

Air leaks in suction line.

Check joints are airtight and inspect

suction pipe.

Impeller and/or wear plate may be

worn.

Replace them by disassembling the

pump

Diameter of the suction pipe too

small

Pump does not

provide enough

pressure

Viscosity of the liquid is higher than

expected

Contact the pump manufacturer once

you have measured the viscosity of

the liquid.

Viscosity for centrifugal pumps

should not exceed 50 cSt

Pump absorbs too

much power

Pump operates under conditions

that are different from those

specified in the contract

Check operating conditions of pump

and compare them to those on the

pump’s nameplate

Density of the liquid is higher than

planned

Measure density of the liquid and

compare it with the agreed value

Check unit is correctly aligned

There may be friction inside the

pump between rotating and non-

rotating components

Disassemble pump casing and check

for scratches on surfaces

Loading...

Loading...