16

12.1.3 Pumps with type TCW - TC8W mechanical seals

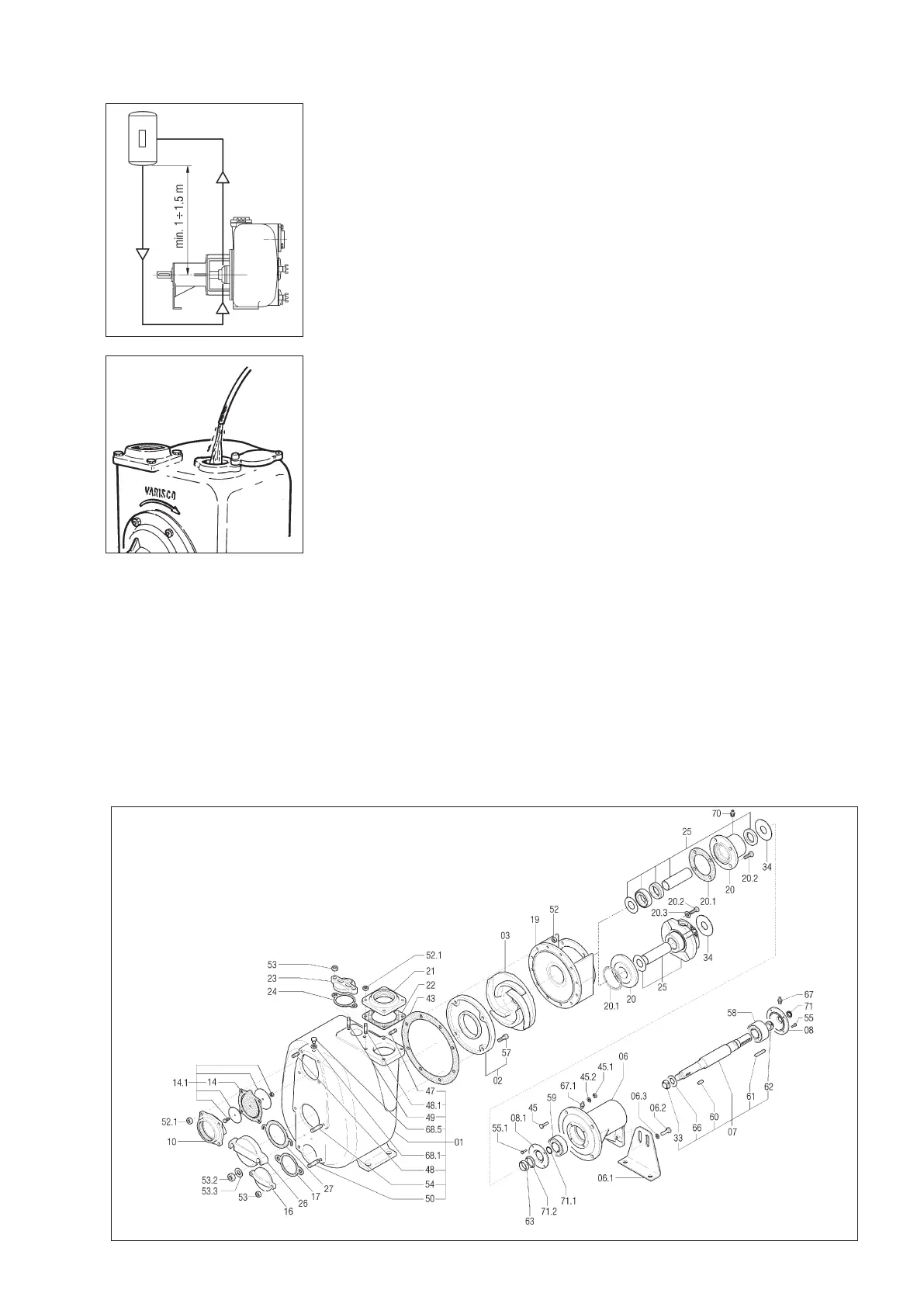

Type TCW, TC8W mechanical seals are flushed according to API 610 Plan 52-53 (see diagram in

fig. 8).

Plan 52 has a non-pressurised tank.

Plan 53 has a pressurised tank with a pressure from 1 to 2 bar higher than the pump operating

pressure.

The flushing liquid must be compatible with the pumped liquid.

12.2 Filling the pump casing

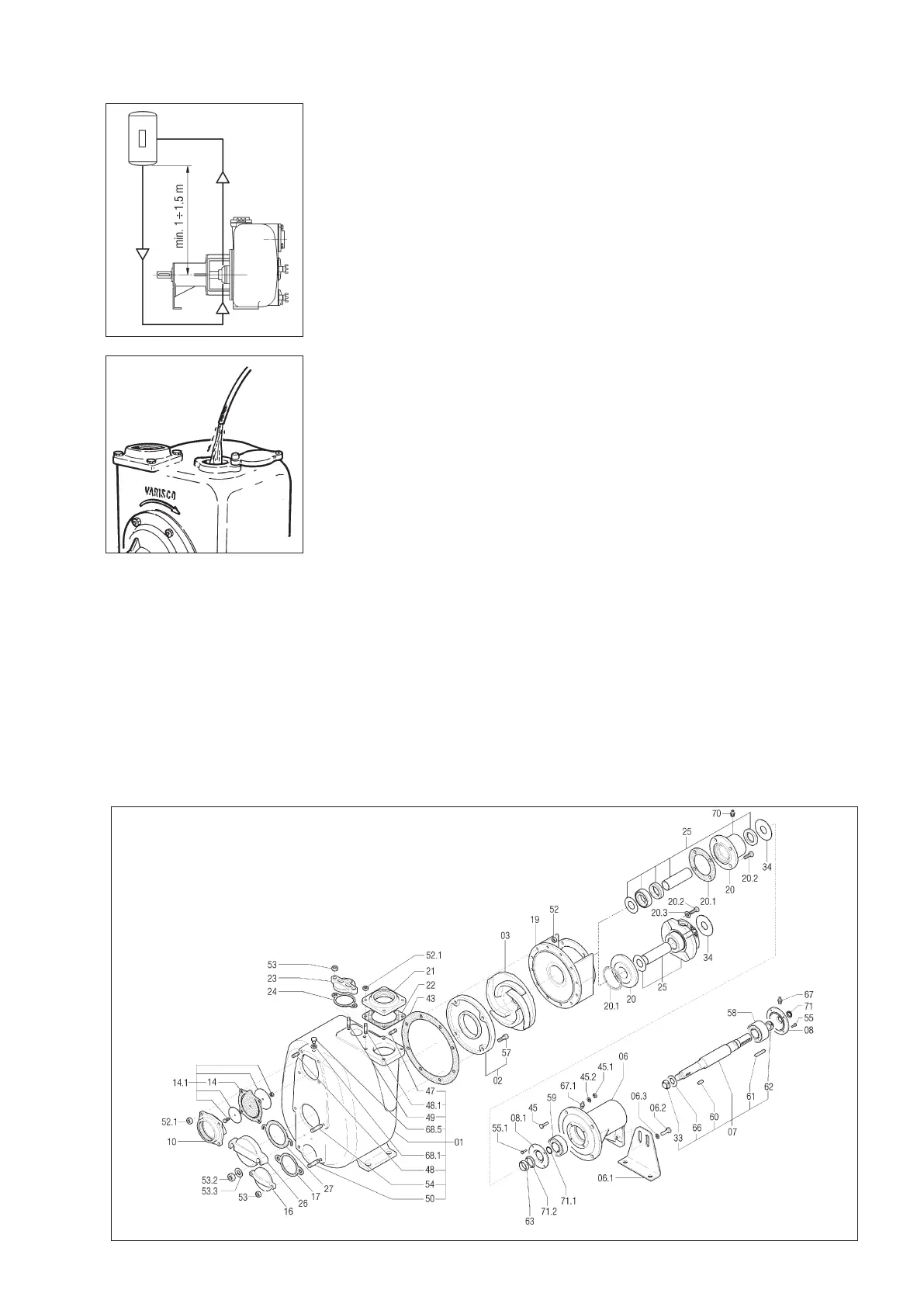

Fill the pump casing completely with the liquid to be pumped through the opening on the top of

the casing (fig. 9). Some models have a plug. When the pump is stopped, the casing does not

empty and therefore it is not necessary to refill it.

12.3 Priming

Attention: if the pump does not prime, do not operate it for more than 2 minutes to avoid

overheating the liquid and damaging the seal.

If the pump does not prime, read paragraph 14.1.

Never exceed the maximum speed shown on the pump name plate.

When the pump has primed:

- Check the shaft seal for leaks.

- Check that the current absorbed by the motor does not exceed the rated value shown on the name plate.

If the pump does not seem to be operating normally, it must be stopped and the cause found (see paragraph 15).

13 MAINTENANCE

Before maintenance is carried out, the pump must be stopped and the electrical supply disconnected. The supply must only

be switched on again by the person who carries out the maintenance.

Attention: residual liquid may be found in the pump casing, head and suction line. Take the necessary precautions if the liquid is

hazardous, inflammable, corrosive, poisonous, infected, etc.

13.1 Inspection and checks

Check from time to time that the pump is working correctly. Use the instruments mounted in the system (pressure gauge, vacuum

gauge, ammeter, etc.) to see if the pump continues to meet its duty.

Periodic maintenance of the parts subject to wear, in particular, the impeller and wear plate, is recommended.

12.1.3 Pumps with type 4 - 5 mechanical seals

Type 4 - 5 mechanical seals are flushed according to API 610 Plan 52-53 (see diagram in fig. 8).

Plan 52 has a non-pressurised tank.

Plan 53 has a pressurised tank with a pressure from 1 to 2 bar higher than the pump operating

pressure.

The flushing liquid must be compatible with the pumped liquid.

12.2 Filling the pump casing

Fill the pump casing completely with the liquid to be pumped through the opening on the top of

the casing (fig. 9). Some models have a plug. When the pump is stopped, the casing does not

empty and therefore it is not necessary to refill it.

12.3 Priming

Attention: if the pump does not prime, do not operate it for more than 2 minutes to avoid

overheating the liquid and damaging the seal.

If the pump does not prime, read paragraph 14.1.

When the pump has primed:

- Check the shaft seal for leaks.

- Check that the current absorbed by the motor does not exceed the rated value shown on the name plate.

If the pump does not seem to be operating normally, it must be stopped and the cause found (see paragraph 14).

13 MAINTENANCE

Before maintenance is carried out, the pump must be stopped and the electrical supply disconnected. The supply must only

be switched on again by the person who carries out the maintenance.

Attention: residual liquid may be found in the pump casing, head and suction line. Take the necessary precautions if the liquid is

hazardous, inflammable, corrosive, poisonous, infected, etc.

13.1 Inspection and checks

Check from time to time that the pump is working correctly. Use the instruments mounted in the system (pressure gauge, vacuum

gauge, ammeter, etc.) to see if the pump continues to meet its duty.

Periodic maintenance of the parts subject to wear, in particular, the impeller and wear plate, is recommended.

fig. 8

fig. 9

fig. 10

Loading...

Loading...