MAINTENANCE

AND

TECHNICAL

INFORMATION

WARNING:

Disconnect spark plug lead

from

spark plug and

wedge

the

terminal

between

cylinder head fins. Ensure

throttle

control

is

set in

"STOP"

position

to

eliminate

fire risk before

attempting

to

clean

mower,

fit

new

blades, or carry

out

any

maintenance

or repairs.

THROTTLE CABLE

ADJUSTMENT

If

at any time the ignition

cut

out

does

not

stop

the

engine when the

throttle

control lever is moved

into

the

STOP position, the

throttle

cable

must

be adjusted.

The procedure

to

adopt

is

as

follows:-

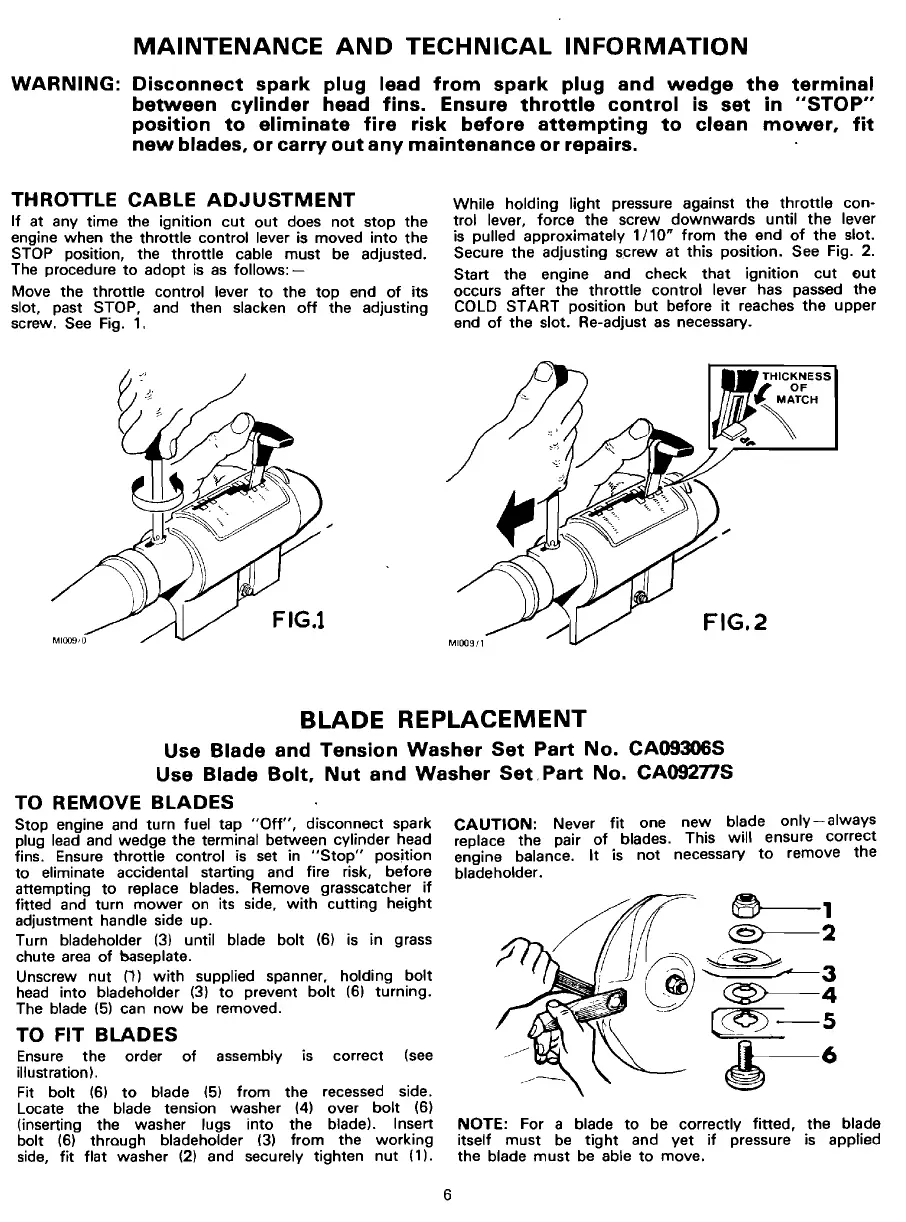

Move the

throttle

control lever

to

the

top

end

of

its

slot, past STOP, and then slacken

off

the adjusting

screw. See Fig.

1.

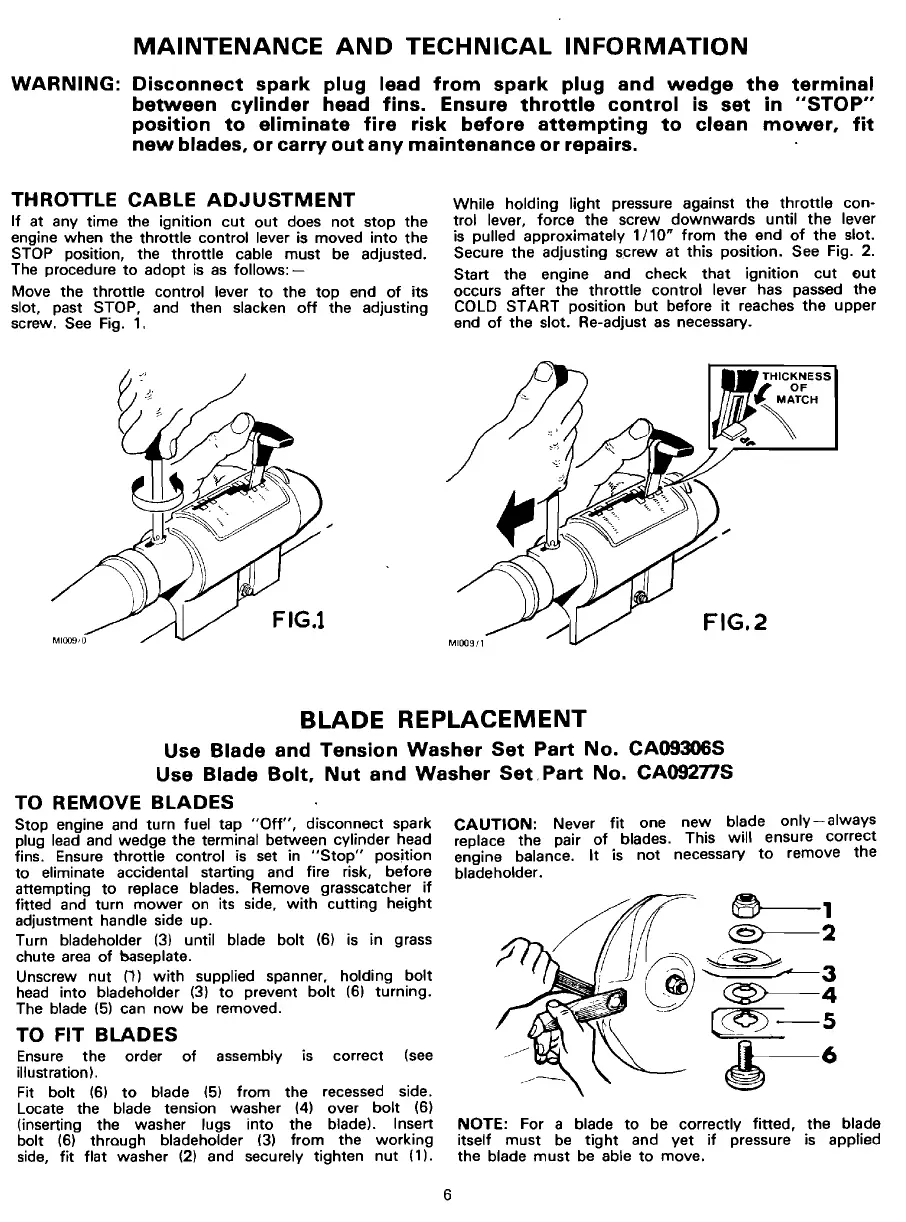

While

holding light pressure against

the

throttle

con-

trol lever,

force

the screw

downwards

until

the

lever

is pulled approximately

1/10"

from

the

end

of

the

slot.

Secure

the

adjusting screw

at

this

position. See Fig. 2.

Start the engine and check

that

ignition

cut

out

occurs

after

the

throttle

control

lever has passed

the

COLD

START

position

but

before

it

reaches

the

upper

end

of

the slot. Re-adjust as necessary.

I

THICKNESS

"

OF

",.~TCH

...

FIG.2

BLADE REPLACEMENT

Use Blade and Tension

Washer

Set

Part

No.

CA09306S

Use Blade

Bolt.

Nut

and

Washer

Set.

Part

No.

CA092nS

TO

REMOVE

BLADES

Stop engine and turn fuel tap

"Off",

disconnect spark

plug lead and wedge

the

terminal between cylinder head

fins. Ensure

throttle

control is set in

"Stop"

position

to

eliminate accidental starting and fire risk, before

attempting

to

replace blades. Remove grasscatcher

if

fitted and turn

mower

on its side,

with

cutting

height

adjustment handle side up.

Turn bladeholder

(3)

until blade

bolt

(6) is in grass

chute

area

of

baseplate.

Unscrew

nut

(1)

with

supplied spanner, holding

bolt

head into bladeholder (3)

to

prevent

bolt

(6)

turning.

The blade

(5)

can

now

be removed.

TO FIT BLADES

Ensure

the

order

of

assembly is correct (see

illustration).

Fit bolt

(61

to

blade (5) from the recessed side.

Locate the blade tension washer (4) over

bolt

(6)

(inserting the washer lugs into the blade). Insert

bolt

(6)

through bladeholder (3)

from

the

working

side,

fit

flat washer (2) and securely tighten

nut

(1).

CAUTION:

Never

fit

one

new

blade

only-always

replace the pair

of

blades. This

will

ensure

correct

engine balance.

It

is

not

necessary

to

remove

the

bladeholder.

NOTE: For a blade

to

be correctly

fitted,

the

blade

itself

must

be

tight

and

yet

if

pressure is applied

the blade

must

be able

to

move.

6

Loading...

Loading...