Art.8800 - Art.8800-3 Digital codelock module

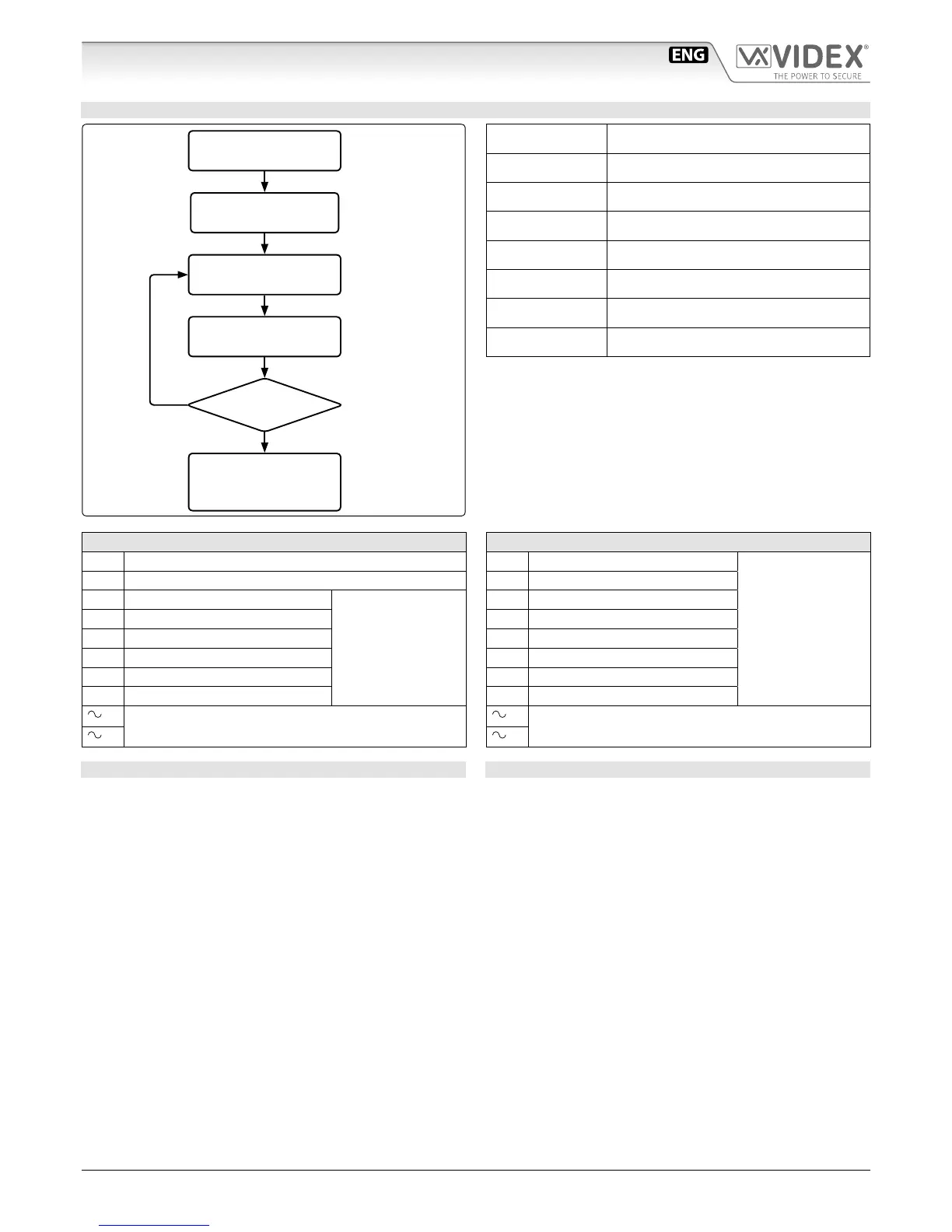

REPROGRMMING GUIDE

ENTER THE

ENGINEER’S CODE

REENTER THE

ENGINEER’S CODE

ENTER

ACCESS CODE

ENTER

ACCESS TIME

PRESS ENTER

TWICE TO EXIT

PROGRAMMING

MORE

DOORS?

Alternatively enter a

new engineer’s code

(4 to 8 digits)

Press Enter

(Red light will illu-

minate*)

Press Enter

Press Enter

Press Enter

Repeat steps for relay 2

and relay 3

***

YES

NO

Relay code (4-8 dig-

its) operate the door

or gate.**

Two digits (01-99

sec or 00 for remain

open)

Engineer’s code

Relay 1 code

Relay 2 code

Relay 3 code***

Relay 1 time

Relay 2 time

Relay 3 time***

Notes:

* If the red light does not illuminate, the engineer’s code is

incorrect. Follow instructions to return system to preset en-

gineer’s factory code.

** On the rst loop of the ow chart its relay 1, second loop is

relay 2 and third loop is relay 3.

*** Only for Art.8800-3

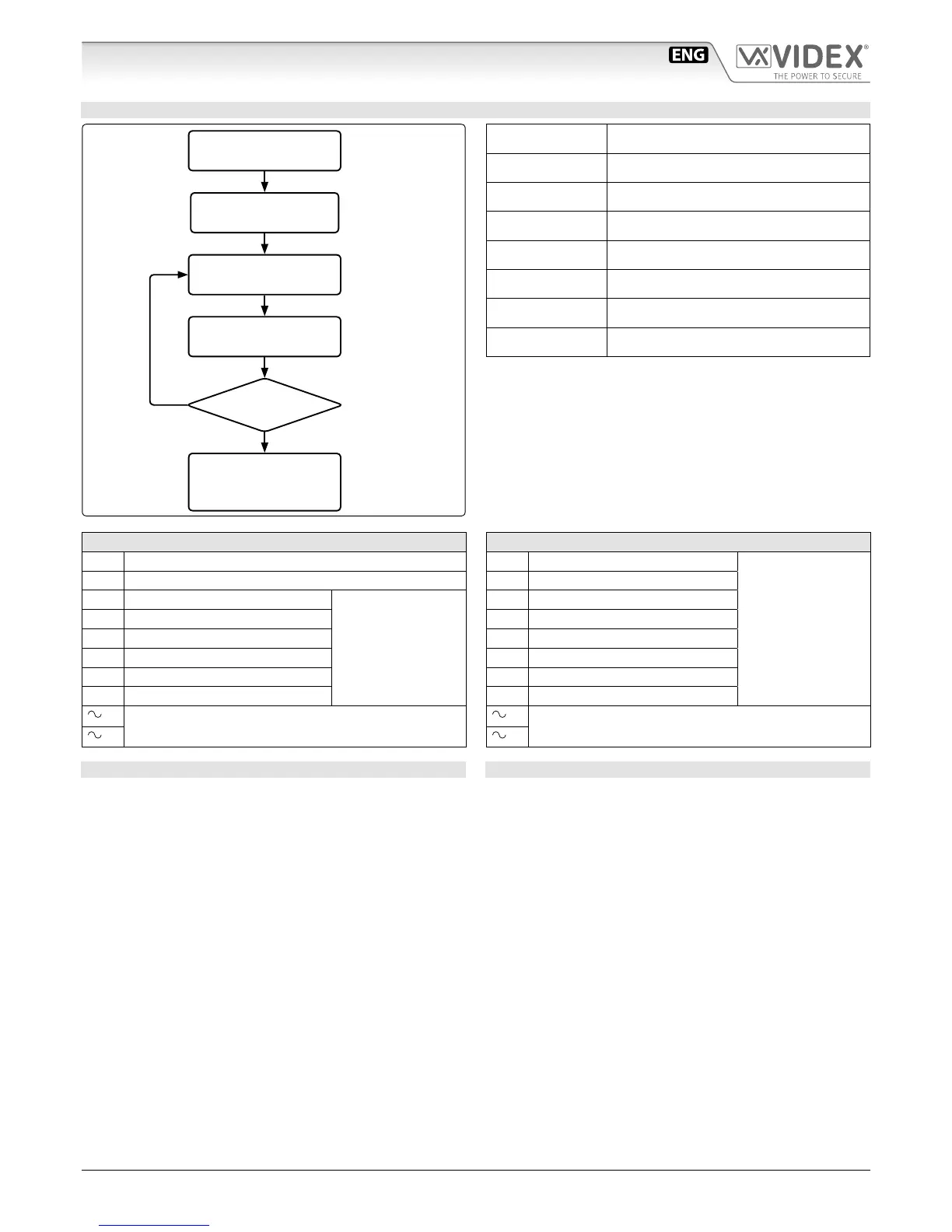

ART.8800 CONNECTION TERMINALS SIGNALS

SW1 Relay 1 command signal (active low)

SW2 Relay 2 command signal (active low)

NC2 Relay 2 normally closed contact

Max

24Vac/dc

5A

NO2 Relay 2 normally open contact

C2 Relay 2 common contact

NC1 Relay 1 normally closed contact

NO1 Relay 1 normally open contact

C1 Relay 1 common contact

/

+

12/24Vac/dc power input

/

–

ART.88003 CONNECTION TERMINALS SIGNALS

NO3 Relay 3 normally open contact

Max

24Vac/dc

5A

C3 Relay 3 common contact

NC2 Relay 2 normally closed contact

NO2 Relay 2 normally open contact

C2 Relay 2 common contact

NC1 Relay 1 normally closed contact

NO1 Relay 1 normally open contact

C1 Relay 1 common contact

/

+

12/24Vac/dc power input

/

–

TECHNICAL SPECIFICATIONS

Power requirements: 12/24V AC/DC, 2VA

Power Consumption: On AC On DC

Stand-by: 82mA 21.5mA

Operating: 125mA 35.0mA

Working Temperature: -10 +50° C

CLEANING OF THE PLATE

Use a clean and soft cloth. Use moderate warm water or non-ag-

gressive cleansers.

Do not use:

• abrasive liquids;

• chlorine-based liquids;

• metal cleaning products.

Loading...

Loading...