28

Gasifying boiler Vigas

17. SERVICE DEPARTMENT

It is advised that repairs to the boiler must be carried out by authorised service engineers appointed by the

manufacturer:

Pavel Vigaš - VIMAR, Príboj 796, Slovenská Ľupča, Slovakia.

tel. 00421 48 41 87 022.

tel. 00421 48 41 87 159

email: vimar@vimar.sk, web: www.vigas.eu

18. PROBLEMS, CAUSES AND SOLUTIONS

During heating season the boiler output is lower

than previous heating period.

Fuel being used is wet.

Clean pipe airway system.

Clean fan air wings.

When chimney flap is closed, boiler does not

perform then smoke appears.

Not enough primary air is getting through. Clean primary pipe

airway system. Check if flap behind the blower is functioning.

Combustion chamber contains unburned wood. Nozzle hole enlarged. Change nozzle. Set up secondary air to

required position : 3 turns of flap back from closed position.

Lower the temperature end. See chap.9.2.

Smoke leaks through door seal after door is

closed.

Door is not tight enough. Adjust the door. Check door is tight.

Remove gasket and place other way round or replace gasket.

Difficulty in opening the chimney flap. Chimney flap is glued by tar. Increase boiler operating

temperature. Use dry fuel. Increase temperature end. See

chap. 9.2.

After upper door and chimney flap is opened,

the boiler room beomes filled with smoke.

Low chimney draught. Chimney diametre must be bigger than

diameter of boiler flue outlet. A discharge fan recommended.

See chap.16.2.

Cracked fireproof/concrete/ filling This is not a defect. Separates combustion chamber from

gasification chamber.

Fan does not turn. It will only start working

when pushed.

Fan condenser is defective . Change condenser.

After heating phase, the boiler shuts down. Incorrect selection of „End“ temperature. See chap.9.2. for

configuration.

Boiler is in shut-down mode, but the fan is still

in operation.

Damaged wires leading to the fan. Zero leading wire is

connected to ground wire

Pump is operating even though the symbol

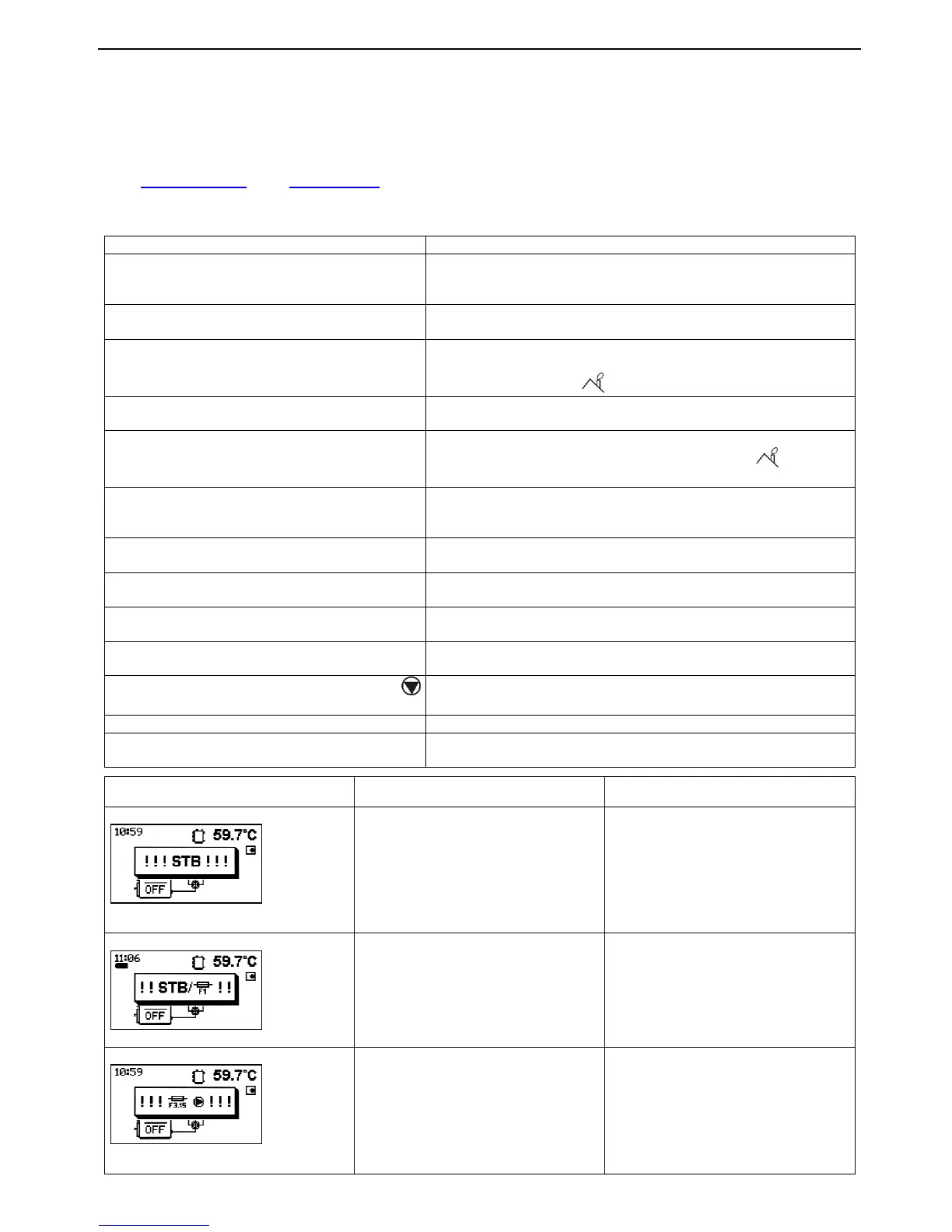

STB Error

Red control LED indicating

Boiler overheated – when boiler

cools down, reset STB fuse

manually. See12.1.

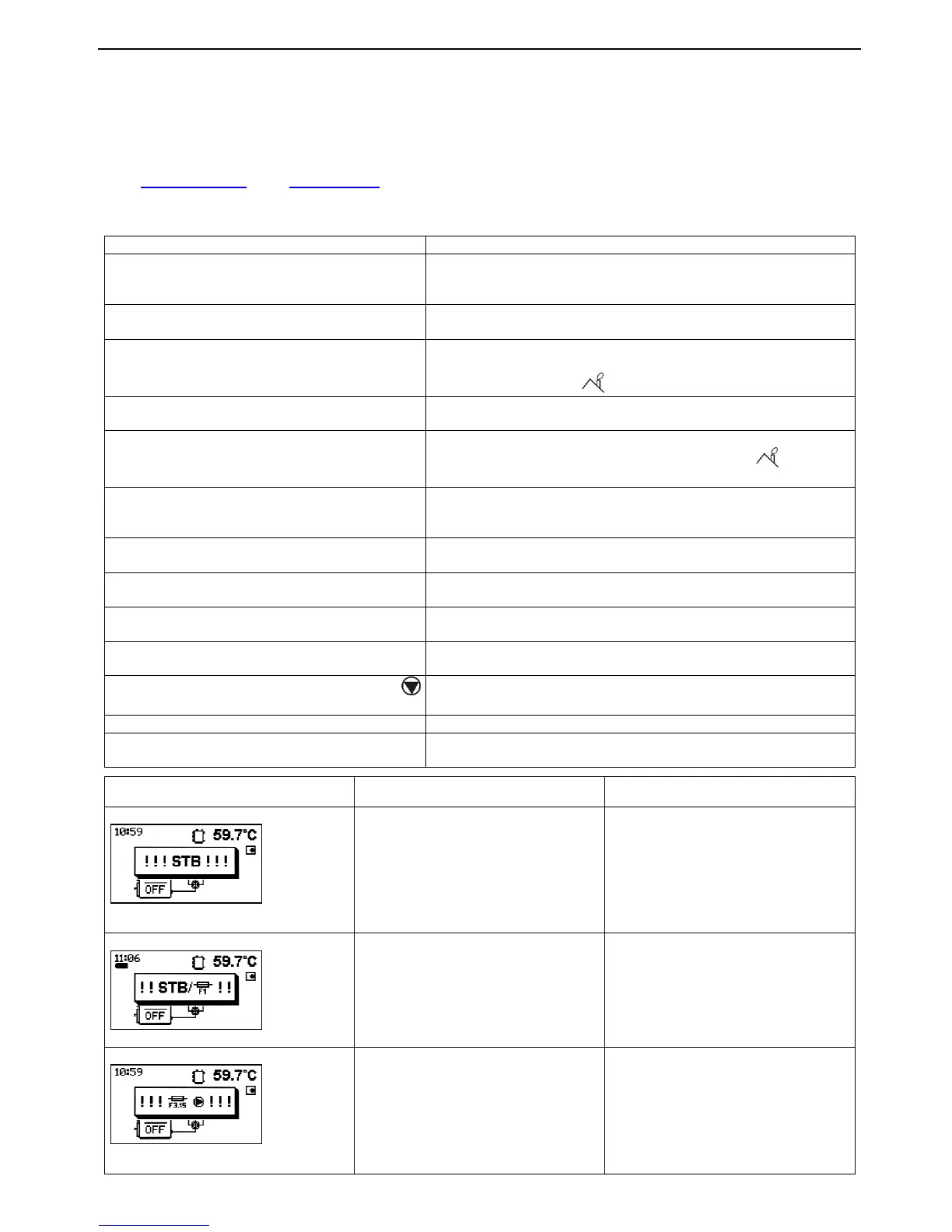

Lambda control boiler STB error

Red control LED indicating

Boiler overheated – when boiler

cools down, reset STB fuse

Suspended fuse F1A, control

system is conencted from

AK4000PS

Suspended fuse 3,15A

Red control LED indicating

Suspended fuse 3,15A which

joins boiler.

Check pump connection.

Loading...

Loading...