6

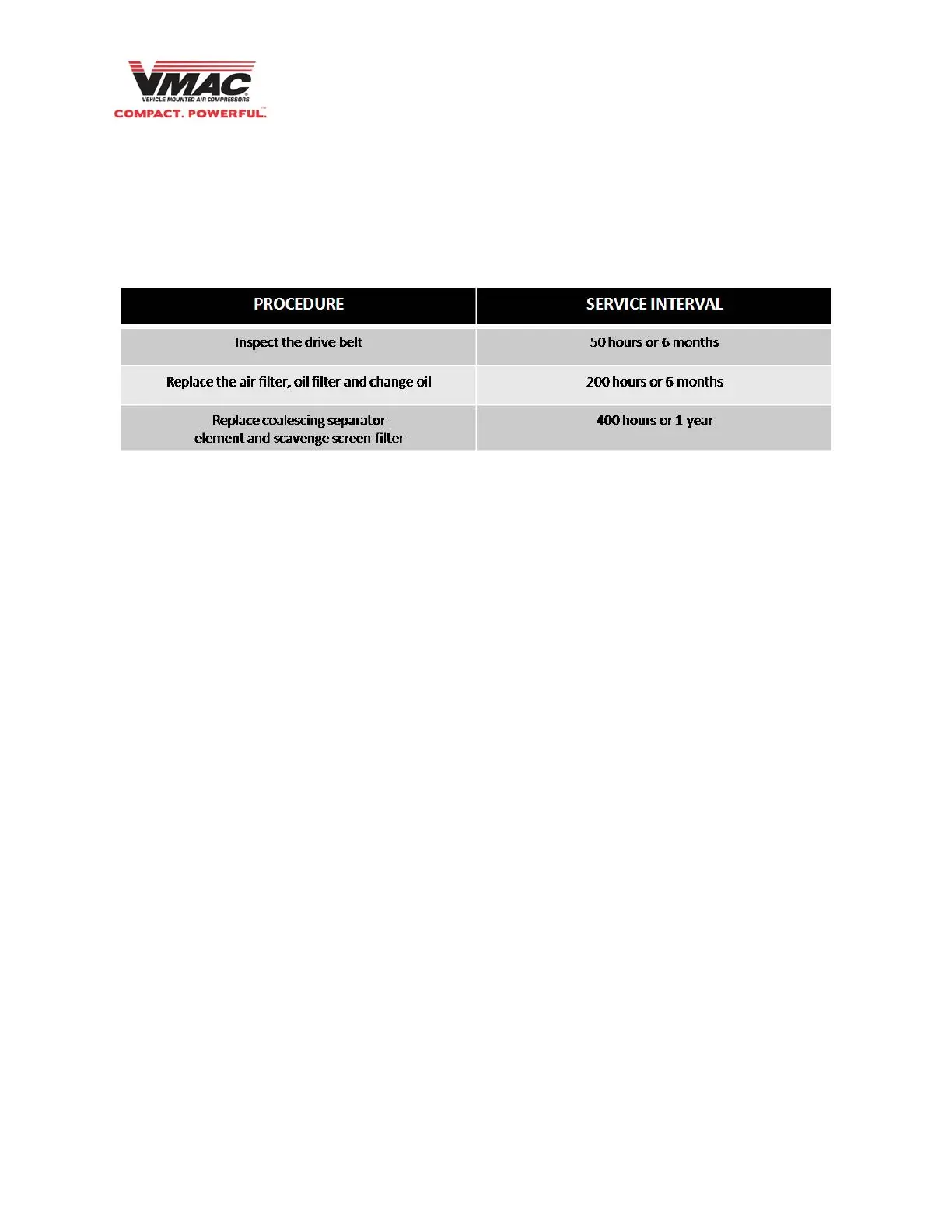

PeriodicMaintenance

Themaintenancescheduleforthesystemisshowninthefollowingtable.Thehoursshownonthetable

arethosedisplayedonthecontrolpanelread‐out.Serviceshouldbeperformedatthelesserofthetwo

intervals,whicheveroccursfirst.Following thisprocedurewillensureoptimumperformanceandlong

life

fromtheVRsystem.

Theseserviceintervalsarebasedonnormaloperation.Commonsenseandgoodmaintenancepractices

willindicatewhethertheseproceduresshouldoccurmorefrequently.Forexample,ifthetruckis

continuouslyoperatinginanextremelydustyenvironment,theairfilterandbeltshouldbeinspected

morefrequently.Sincethecompressordraws

inlargequantitiesofairduringoperation,thefiltermay

becomepluggedandwillaffectoperation.

InspectingtheDriveBelt

Periodicinspectionofthedrivebeltisnecessarytoidentifypotentialproblemsbeforetheycausefailure

ordamage.WhileVMACrecommendsa50hourinterval,iftheoperatingenvironmentissevere,you

shouldinspectthebeltmorefrequently.

Checkthebeltcarefullyforsignsofglazing,missingportionsoftheribs

ordamagetotheedgesor

surface.Ifthereisdamage,itmayindicateaproblemwithpulleyalignmentorimproperusebythe

operator.Installinganewbeltwillnotcorrecttheproblem,itwilljustresultindamagetothenewbelt.

Abeltthatisheat‐damaged

indicatesthatthebeltisslippingonthecompressororcrankshaftpulleys.

Thismaybecausedbyadefective tensionerorbytheoperatorengagingthecompressorwhilethereis

pressureinthesystem.Thiscancausethecompressorclutchtostallandthebeltwillslip.Ifthe

tensioneris

applyingsufficientpressureandismaintainingbelttensioncorrectly,talktotheoperator

andfindouthowtheyareusingthesystem.Inspecttheidlers,pulleysandtensionerfordamage.Any

componentthatshowschips,cracksorotherphysicaldamageshouldbereplaced.

Ifthebeltisdamagedorworn

alongtheedges,itcouldindicateanalignmentproblem.Ifthisoccurs,

checkthealignmentofallpulleys,idlersandtensionerswithastraightedge.Ifthereisanalignment

problem,checkallsystemfastenerstomakesurethattheyaretight.Alsocheckforcrackingordamage

onthe

mountingbracketandatthecompressor.

Loading...

Loading...