33

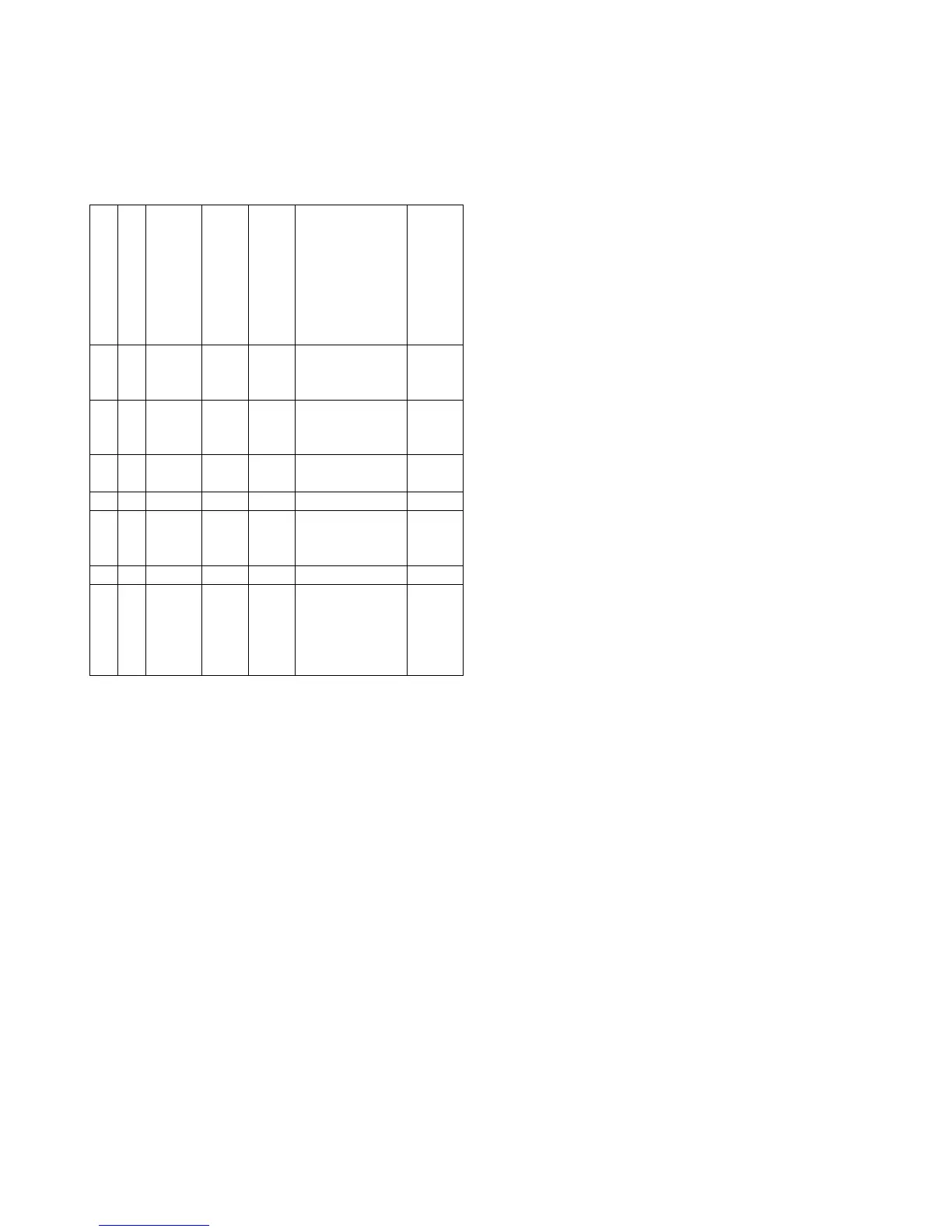

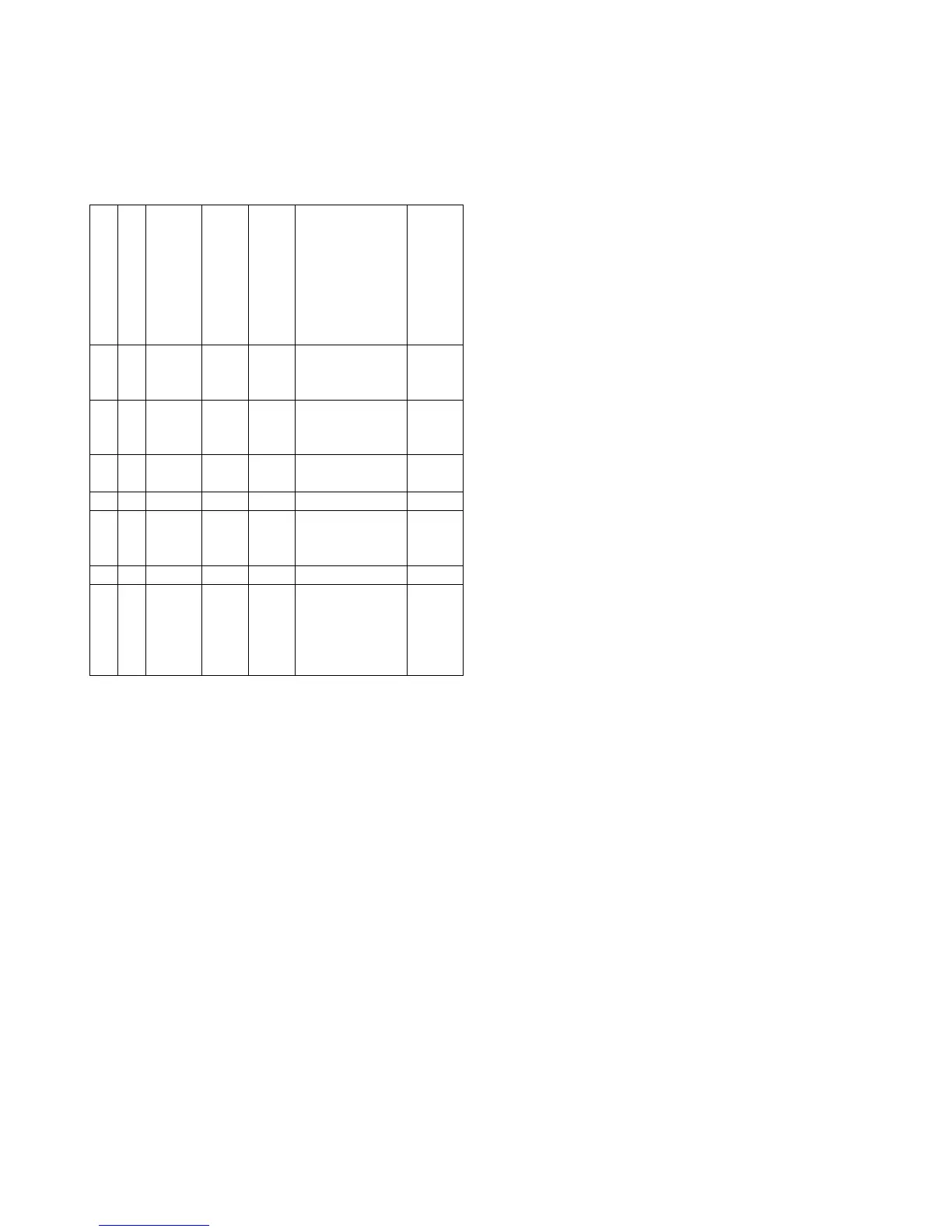

FAULT TRACING

The fault-tracing scheme below includes only those

faults which arise most often during operation.

Fault-tracing scheme

Engine does not start

Engine stops

Engine does not reach

right operating speed at

ull throttle

Engine runs unevenly or

vibrates abnormally

Engine becomes

abnormally hot

FAULT Notes

X

Main switch not on,

flat battery, broken

electric cables

A

X X

Empty fuel tank,

closed fuel cock,

blocked fuel filter

B

X X X

Water, air or

impurities in fuel

B

X X X X Defective injectors C

X

Boat abnormally

loaded. Growth on

boat bottom.

D

X X Damaged propeller E

X

Clogging of cooling

water intake,

cooling jackets,

defective impeller

or thermostat

F

A.

Check the state of charge of the battery with the help

of a hydrometer which shows the specific gravity of the

battery acid. This will vary with the state of charge, see

under “Technical Data”. Also see under “Electrical

system” on page 23.

B. Replace the fine filter by turning the hex head in the

bottom of the container. The fine filter and container

are of the throw-away type. They must be discarded

and a new one installed. Check that the contact

surface for the cover is absolutely clean and that the

filter gasket is in good condition. Screw on the new

filter tight by hand until the gasket goes against the

cover. Then tighten the filter a further 1/2 turn. The

bottom of the filter container has a drain plug for

draining water and impurities that have accumulated in

the fuel. Bleed the fuel system after draining and

replacing the filter, also check for leakage.

Remove the feed pump cover and clean the pre-filter

in the fuel oil. Then fit the filter with the pins facing

upwards and place the gasket (undamaged) in position

and tighten up the cover. Bleed the fuel system.

Check and if necessary drain the extra fuel filter if such

is fitted. Look out for fuel splash.

Bleeding the fuel system

To ensure that the engine starts, the fuel system must

be bled on the following occasions: 1) When changing

the fine filter. 2) When draining through the drain plug.

3) When cleaning the pre-filter. 4) When running the

fuel tank empty. 5) When installing the fuel injection

pump. 6) With leakage and when working on the fuel

line. 7) When the engine has been stopped for a long

time. Bleeding is as follows: Open the bleeder screw 1

on the fine filter. See Point 68. Pump forward the fuel

with the help of a hand primer until about 0.2 litre (0.2

qt.) fuel has run out. Close the bleeder screw. If you

get poor pumping effect, turn over the engine a bit so

that the pump drive cam alters its position. If the fuel

injection pump has been removed, or when starting an

entirely new engine for the first time, the fuel injection

pump must be bled. Pump with the hand primer for

about 1/2 minute. This automatically bleeds the fuel

injection pump. Slacken the delivery pipe nuts for the

injectors and turn over the engine with the start-

generator until fuel comes from the delivery pipes.

Tighten up the delivery pipe nuts and start the engine.

C. Check the injectors with regard to their opening

pressure, tightness and spray pattern. Max. running

time of 400 operating hours or once a season is

recommended between these checks. See also Points

37 and 38.

D. In order to get the best possible operating economy,

the engine speed selected should be minimum 300

rev/mm below the max. speed for The engine during

lengthy periods of operation. When the boat has been

in the water for so’ time, the max. speed for the engine

can drop due to growth on the outside of the hull. Use

anti-fouling paint. Check and clean the hull regularly.

E. Check the propeller blades. If a propeller blade is

damaged, the propeller must be replaced. A propeller

blade can also be warped, something which is very

difficult to discover. Place the propeller on a flat disc

and measure the blades. If a propeller blade is

warped, the propeller should be replaced.

F. Check the cooling system for leakage, clogging, etc.

Check to make sure the thermostat opens at the right

temperature. The thermostat can be removed after

having taken down the thermostat housing at the front

of the exhaust manifold. See also Point 49. The pump

body in the sea-water pump is made of neoprene

rubber, which can be damaged with shortage of water,

e.g., in the event the sea-water inlet is blocked.

Proceed according to Points 45-48 in the event the

impeller and sealing rings have to be replaced. NOTE!

If the boat is in the water, the bottom cock must be

closed before the sea-water pump is removed. But do

not forget to open the cock again.

Loading...

Loading...