Group 21 Reconditioning engine

Cleaning, checking

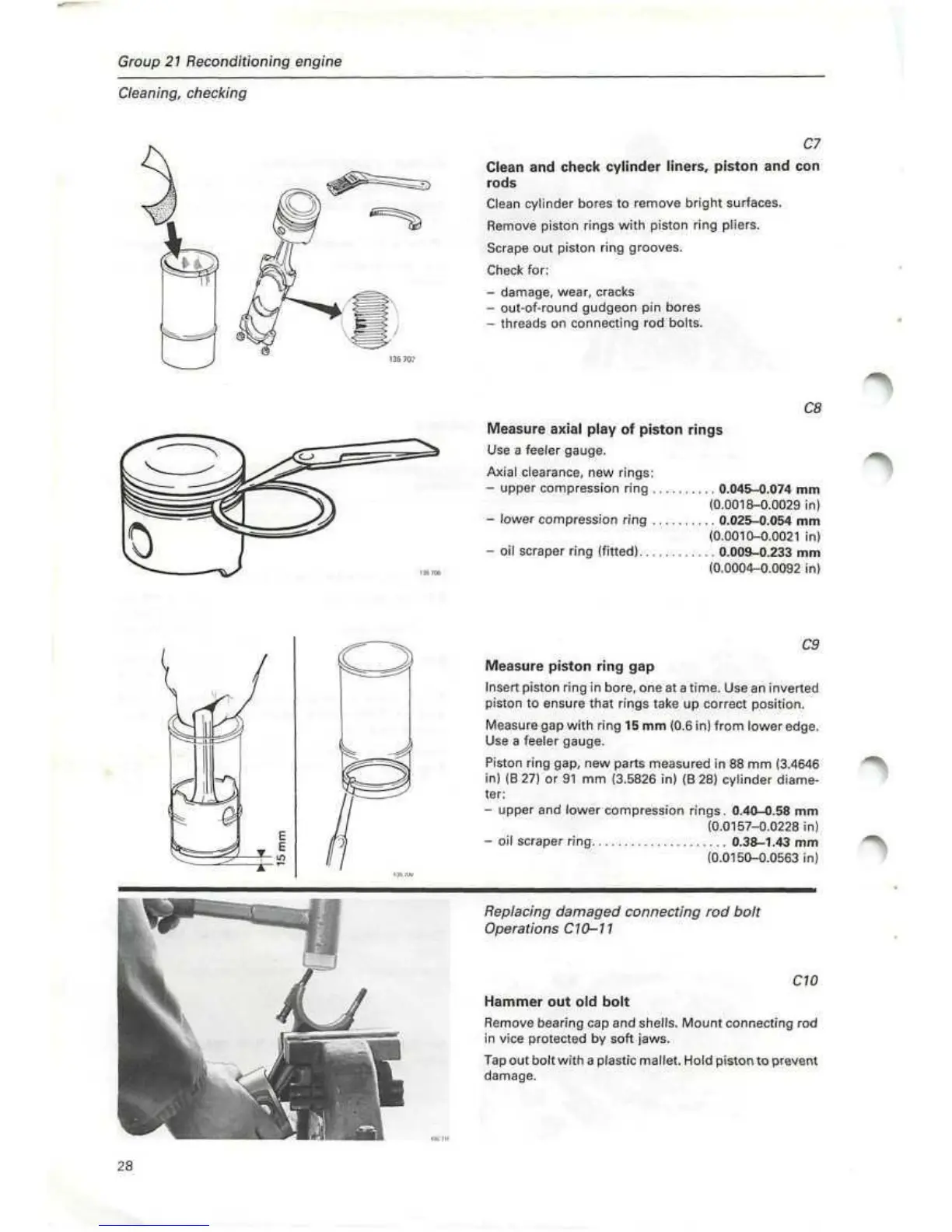

C7

Clean and check cylinder liners, piston and con

rods

Clean cylinder bores to remove bright surfaces.

Remove piston rings with piston ring pliers.

Scrape out piston ring grooves.

Check for:

- damage, wear, cracks

- out-of-round gudgeon pin bores

- threads on connecting rod bolts.

13S706

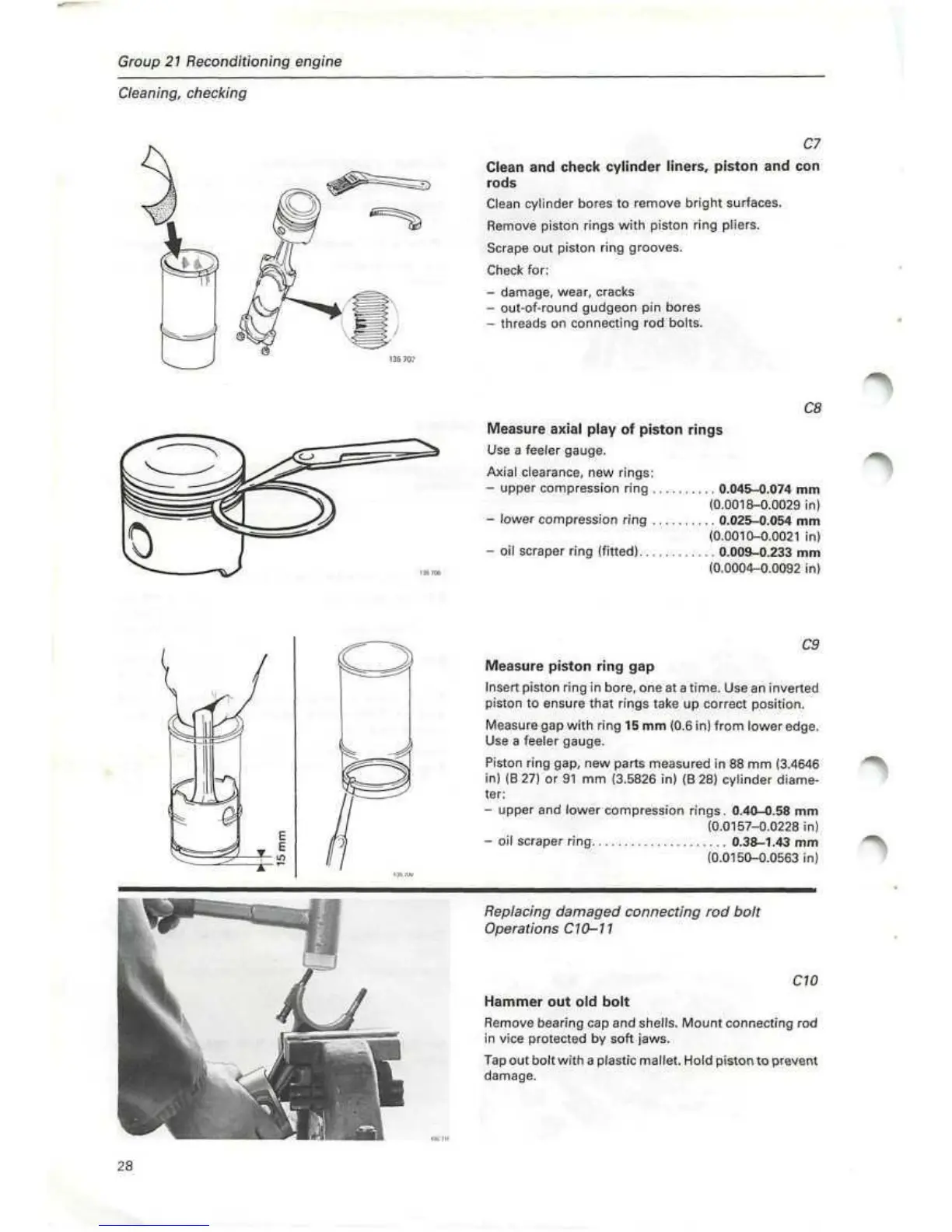

C8

Measure axial play of piston rings

Use a feeler gauge.

Axial clearance, new rings:

- upper compression ring 0.045-0.074 mm

(0.0018-0.0029

in)

- lower compression ring 0.025-0.054 mm

(0.0010-0.0021

in)

- oil scraper ring (fitted) 0.009-0.233 mm

(0.0004-0.0092 in)

C9

Measure piston ring gap

Insert piston ring in bore, one at a time. Use an inverted

piston to ensure that rings take up correct position.

Measure gap with ring 15 mm (0.6 in) from lower edge.

Use a feeler gauge.

Piston ring gap, new parts measured in 88 mm (3.4646

in)

(B27)

or 91 mm (3.5826 in) (B 28) cylinder diame-

ter:

- upper and lower compression rings. 0.40-0.58 mm

(0.0157-0.0228 in)

- oil scraper ring

0.38-1.43

mm

(0.0150-0.0563 in)

Replacing damaged connecting rod bolt

Operations

CI0-11

CIO

Hammer out old bolt

Remove bearing cap and shells. Mount connecting rod

in vice protected by soft jaws.

Tap out boltwith a plastic mallet. Hold piston to prevent

damage.

28

Loading...

Loading...