r

r

Group

21

Reconditioning engine

Cleaning, checking

C11

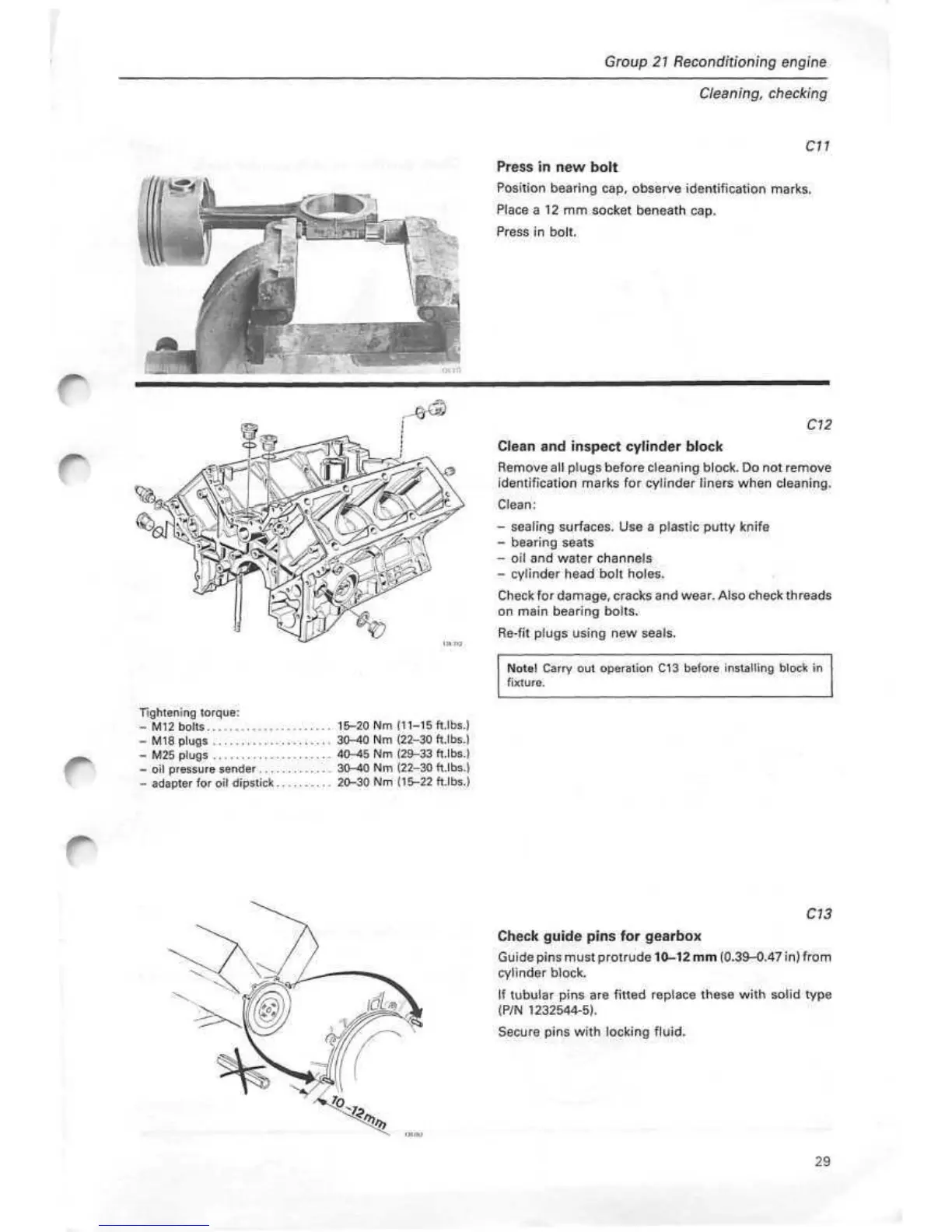

Press in new bolt

Position bearing cap, observe identification marks.

Place a 12 mm socket beneath cap.

Press in bolt.

A^

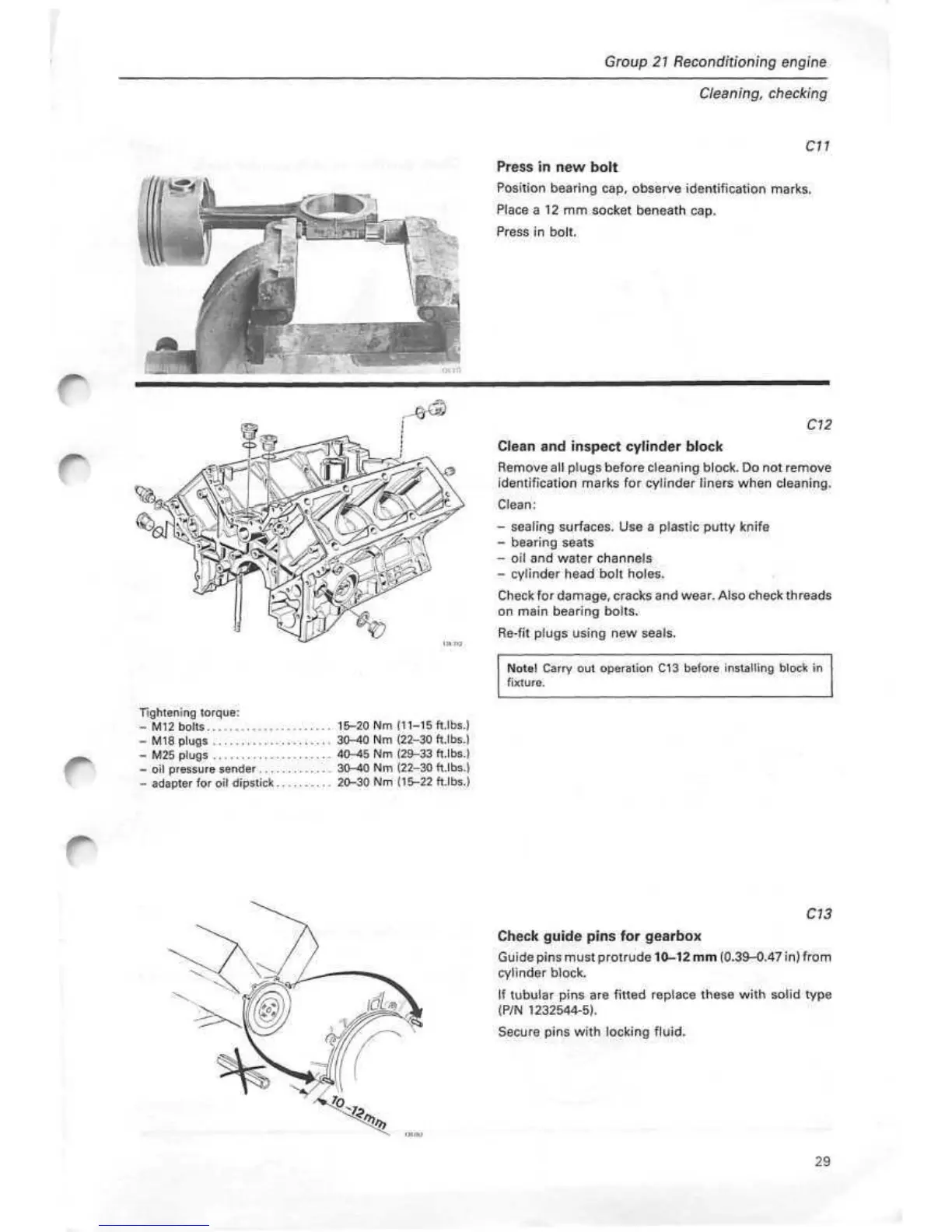

Tightening torque:

- M12 bolts

15-20 Nm (11-15 ft.lbs.)

- M18 plugs

30-40

Nm (22-30 ft.lbs.)

-

M25

plugs

40-45

Nm (29-33 ft.lbs.)

- oil pressure sender

30-40

Nm (22-30 ft.lbs.)

- adapter for oil dipstick

20-30

Nm (15-22 ft.lbs.)

C12

Clean and inspect cylinder block

Remove all plugs before cleaning block. Do not remove

identification marks for cylinder liners when cleaning.

Clean:

- sealing surfaces. Use a plastic putty knife

- bearing seats

- oil and water channels

- cylinder head bolt holes.

Check for damage, cracks and wear. Also check threads

on main bearing bolts.

Re-fit plugs using new seals.

Note!

Carry out operation C13 before installing block in

fixture.

C13

Check guide pins for gearbox

Guide pins must protrude 10-12 mm (0.39-0.47 in) from

cylinder block.

If tubular pins are fitted replace these with solid type

{P/N 1232544-5).

Secure pins with locking

fluid.

29

Loading...

Loading...