Group

21

Reconditioning engine

^^i|

J-T-U

'

Assembly

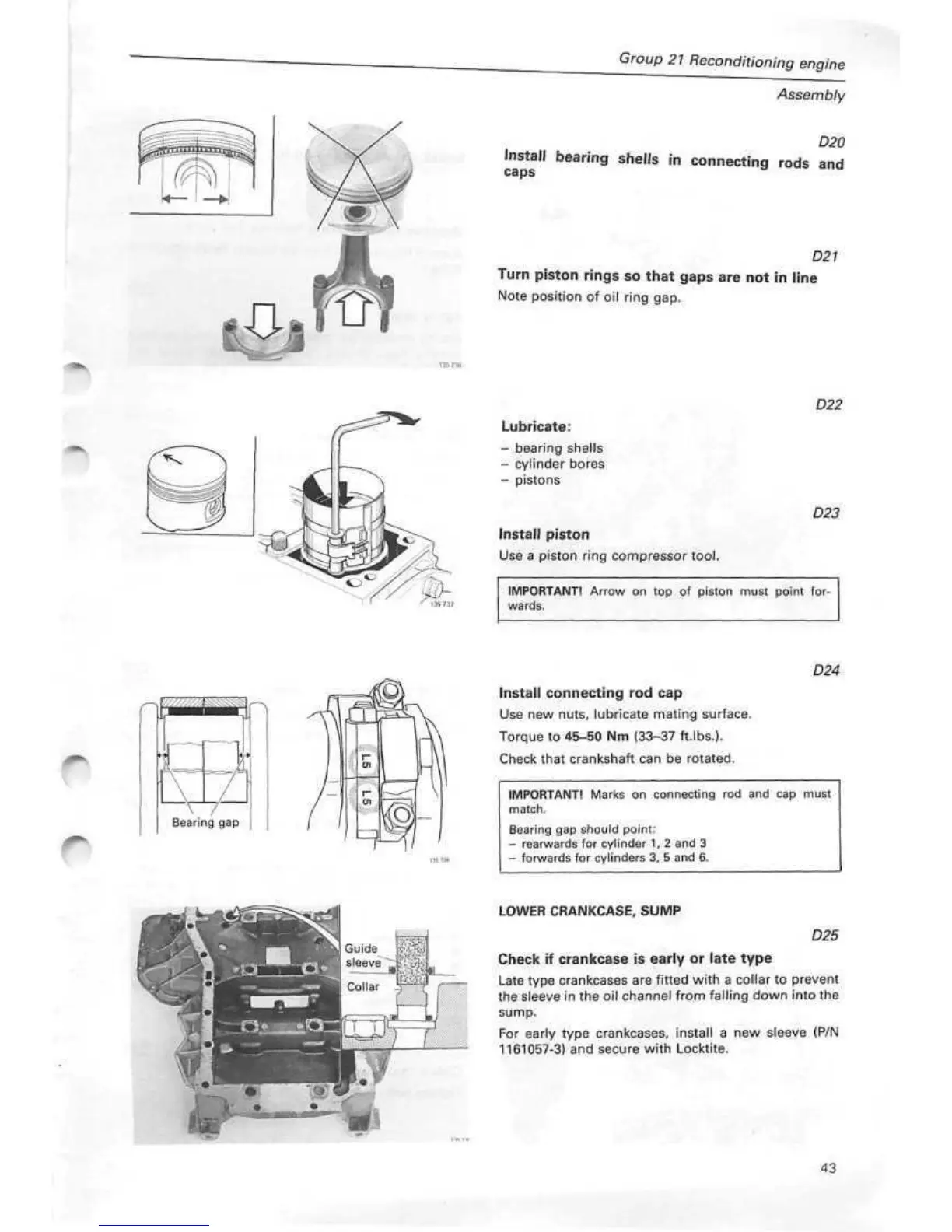

D20

Install bearing shells in connecting rods and

caps

D21

Turn piston rings so that gaps are not in line

Note position of oil ring gap.

D22

Lubricate:

- bearing shells

- cylinder bores

- pistons

Install piston

Use a piston ring compressor

tool.

D23

IMPORTANT! Arrow on top of piston must point for-

wards.

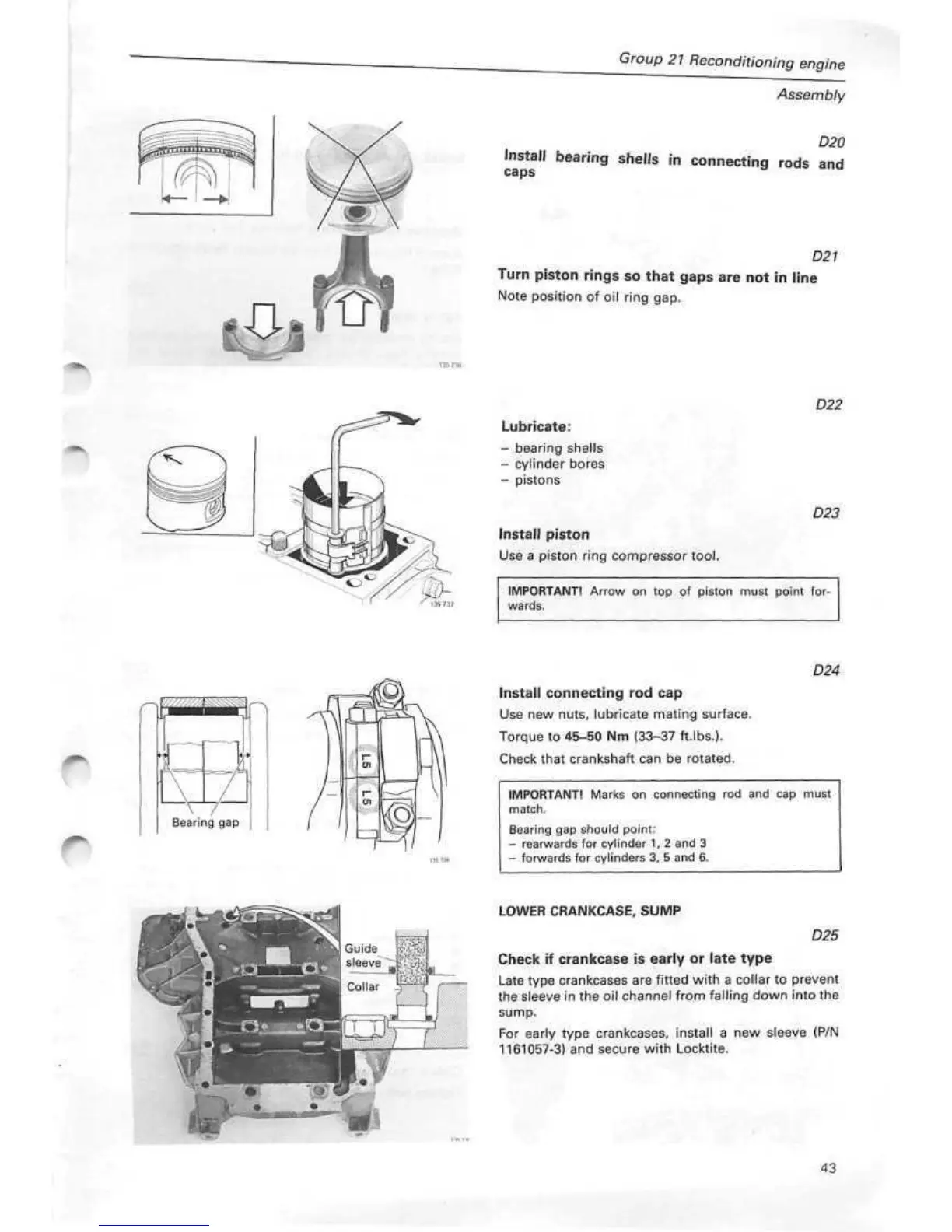

D24

Install connecting rod cap

Use new nuts, lubricate mating surface.

Torque to

45-50 Nm (33-37

ft.lbs.).

Check that crankshaft can be rotated.

IMPORTANT! Marks on connecting rod and cap must

match.

Bearing gap should point:

- rearwards for cylinder 1, 2 and 3

- forwards for cylinders 3, 5 and 6.

LOWER CRANKCASE, SUMP

uide

eeve

Collar

V " r

§

£iJ

J_

i—

j

D25

Check if crankcase is early or late type

Late type crankcases are fitted with a collar to prevent

the sleeve in the oil channel from falling down into the

sump.

For early type crankcases, install a new sleeve (P/N

1161057-3)

and secure with Locktite.

43

Loading...

Loading...